3

2. Operation Overview

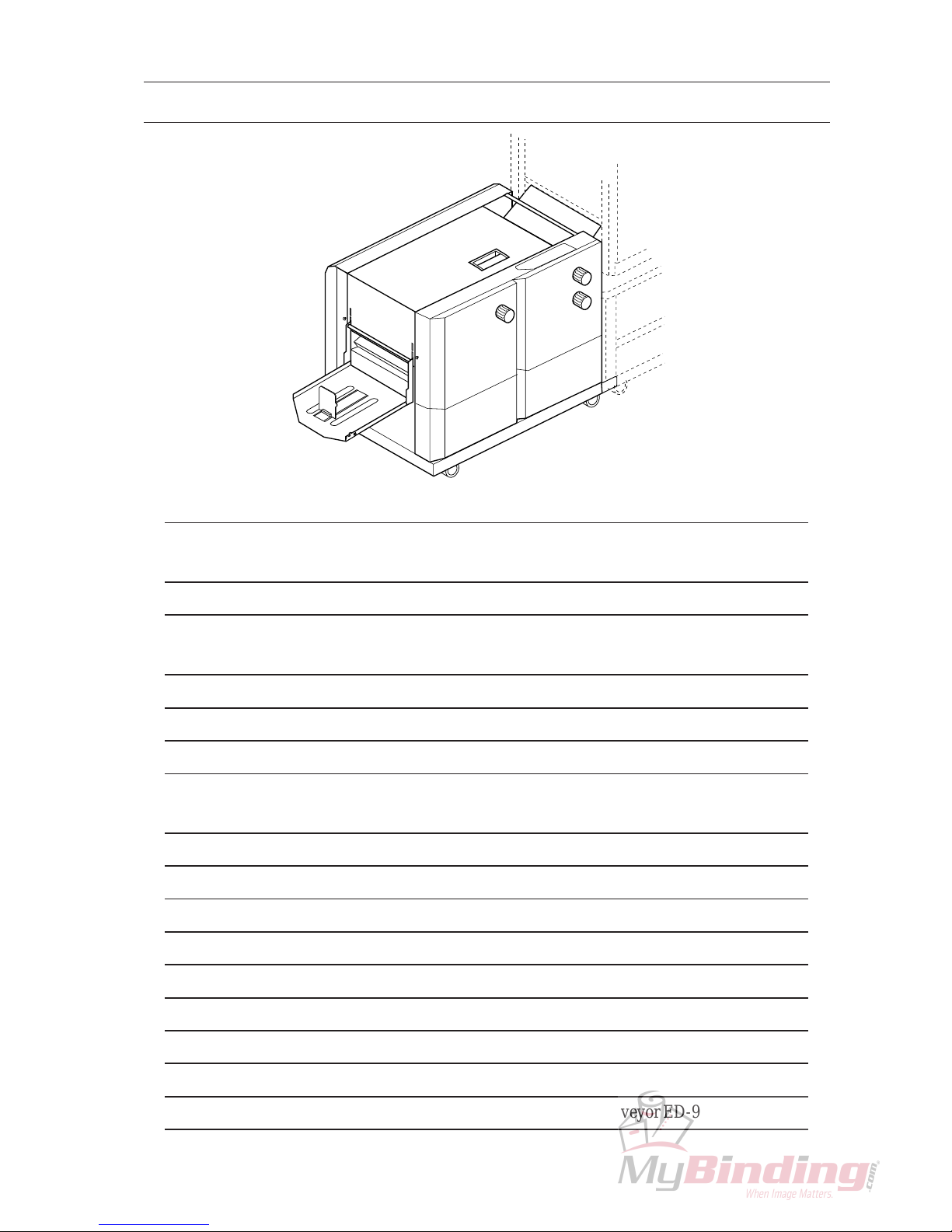

2-1 SPF-9

Connecting cable on SPF-9 is connected to collator.

1. Turn on power switch on SPF-9.

On operation panel,

- automatic mode lamp will illuminate.

- stapling & folding lamp will illuminate.

2. Turn on power switch on collator.

3. Pile sheets into collator and set required set up on SPF-9 following "2-1 Operation Procedure"

procedure 5 to 20 (page15 to 18) in SPF-9 Operation Manual.

4. Select automatic mode with function mode select button.

5. Press start button on collator.

- Sheets delivered from collator will be stapled automatically.

6. Press stop button on collator to stop SPF-9.

SPF-9 will stop without pressing stop button in the following cases.

- Sheet jam, misfeed, and double feed occur in collator. Collator lamp on SPF-9 illuminates.

- Sheets are jammed in SPF-9. Sheet jam lamp on SPF-9 illuminates.

- Sheet jam, misfeed and double feed occur

in collator.

- Sheets are jammed in SPF-9.

- Sheets are jammed in FC-9.

- Upper knife stops at the middle of cutting

process.

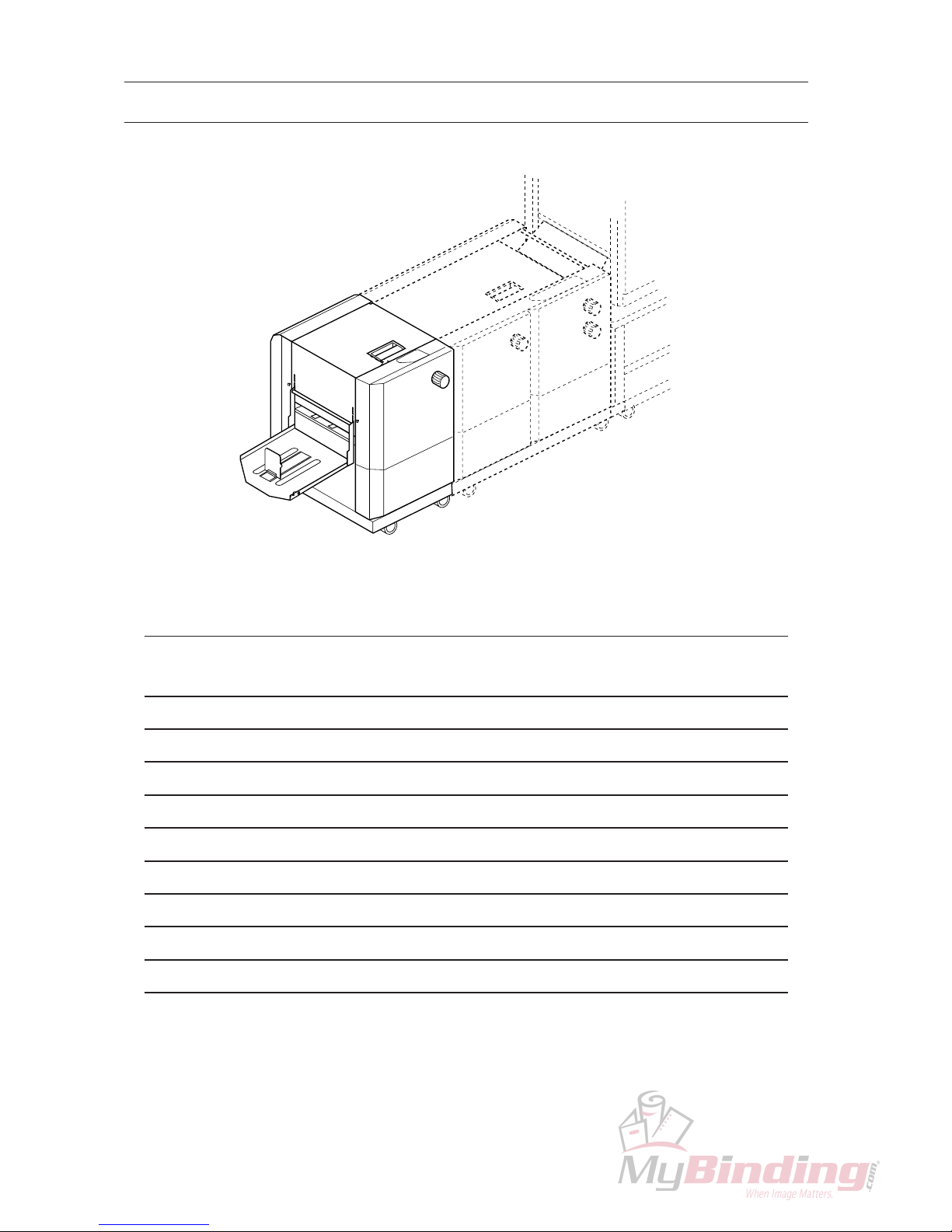

Cable on FC-9 is connected to SPF-9.

1. Turn on power switch on SPF-9.

2. Turn on power switch on collator.

3. Pile sheets into collator and set required set up on SPF-9 and FC-9 following "2-1 Operation

Procedure" 5 to 20 (page 15 to 18) in SPF-9/FC-9 Operation Manual.

4. Select automatic mode with function mode select button.

5. Press start button on collator.

- Sheet delivered from collator will be stapled and folded in SPF-9 and be cut in FC-9 auto-

matically.

6. Press stop button on collator to stop SPF-9.

SPF-9 will stop without pressing stop button in the following cases.

- Collator lamp in SPF-9 will illuminate.

- Sheet jam lamp on SPF-9 will illuminate.

- Jam lamp will illuminate.

- Knife lock lamp will illuminate.

2-2 FC-9