+1 (813) 783-8058

Fax: +1 (813) 783-2407

Wiring Instructions

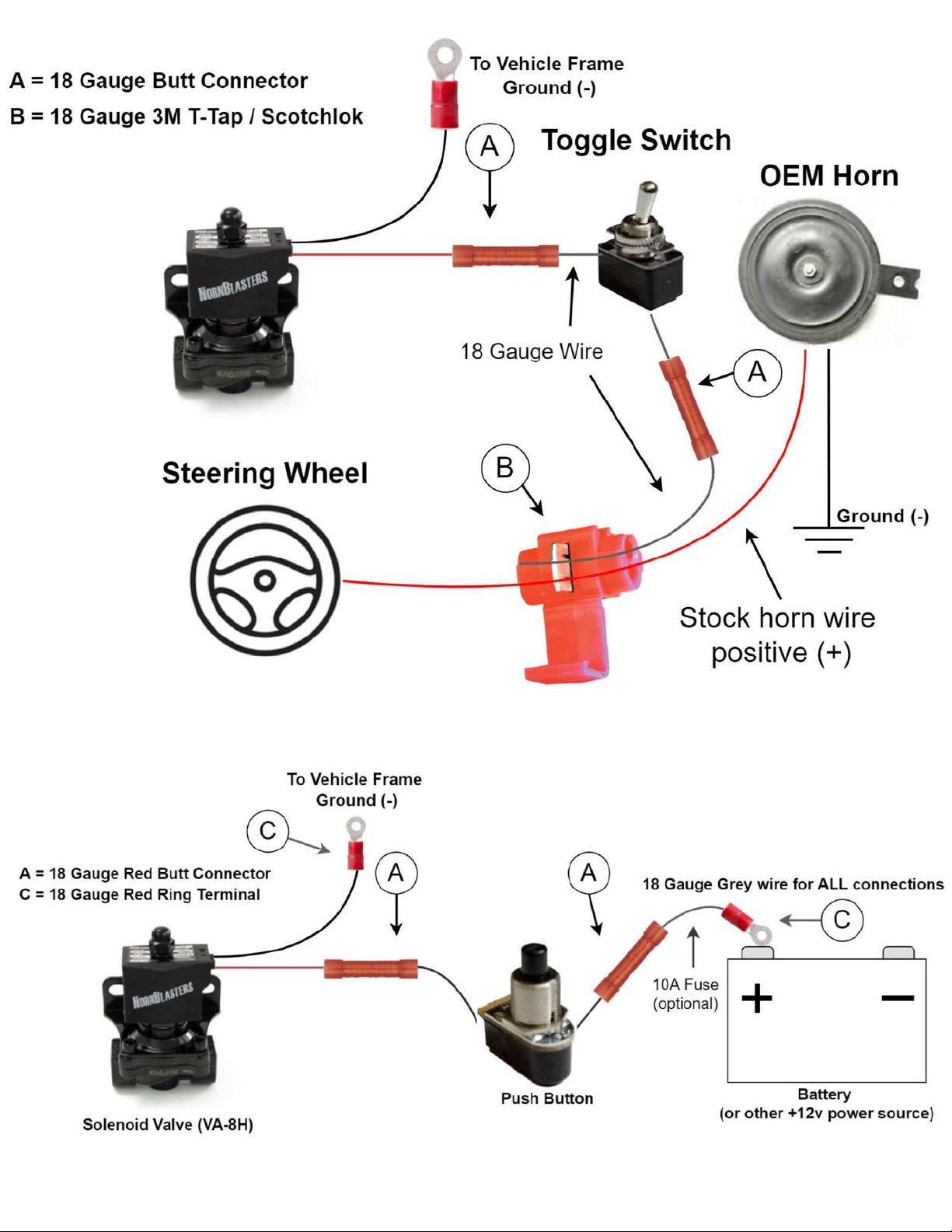

Wiring the Relay

Pin 30: This pin will connect to the battery positive terminal. You MUST use the supplied 10-gauge RED

wire for this connection. Use the supplied tan or green terminal to connect the red wire to this pin. Cut the

fuse holder wire in half at the center point. Connect one end to the battery positive terminal. Connect the

other end to a lead of 10 ga. red power wire that runs back to the relay.

Pin 86: This pin will connect to a key-power source. You are looking to connect this pin to any circuit that is

ONLY ON WHEN THE VEHICLE IS ON. This will prevent your kit from running when the vehicle is off.

Common key-power sources include the cigarette lighter fuse, sunroof, radio, trailer running lights, daytime

running lights, etc. You can use any circuit that is rated for 5A or less. The relay only needs a fraction of an

amp to operate.

Pin 85: Route a lead from this pin to the frame of the vehicle as a ground point. You may use the supplied

Blue or Grey wire for this connection. You can use a wire brush on the frame or bed coating to ensure a

good connection to metal is made.

Pin 87: Take the red lead coming off the compressor/tank combo and connect it directly to this pin.

Your relay is now wired and ready for use. You can use a small lead of wire to connect pins 30 & 86

together to test the relay. If you have this wired correctly, the relay should make a light 'click' sound when

the two pins are connected. This means the relay is turning on and off properly. When you start the

vehicle, it will send power to pin 86 and turn the relay on, which will allow the compressor to run.

Key-Power-Source (Normal Method)

If you're having trouble locating a fuse that is only hot when the vehicle is on, you can go online to https://

fuse-box.info/. You can use a test light to check whether or not the fuses are hot with the key in the off

position. Route the black probe/clip to the battery negative terminal (-) and use the red probe on the metal

contacts of the fuse(s) you want to check. If the light comes on, your fuse is hot. If the light does not turn

on, start the vehicle and check for current. The light should illuminate now that the vehicle is running.

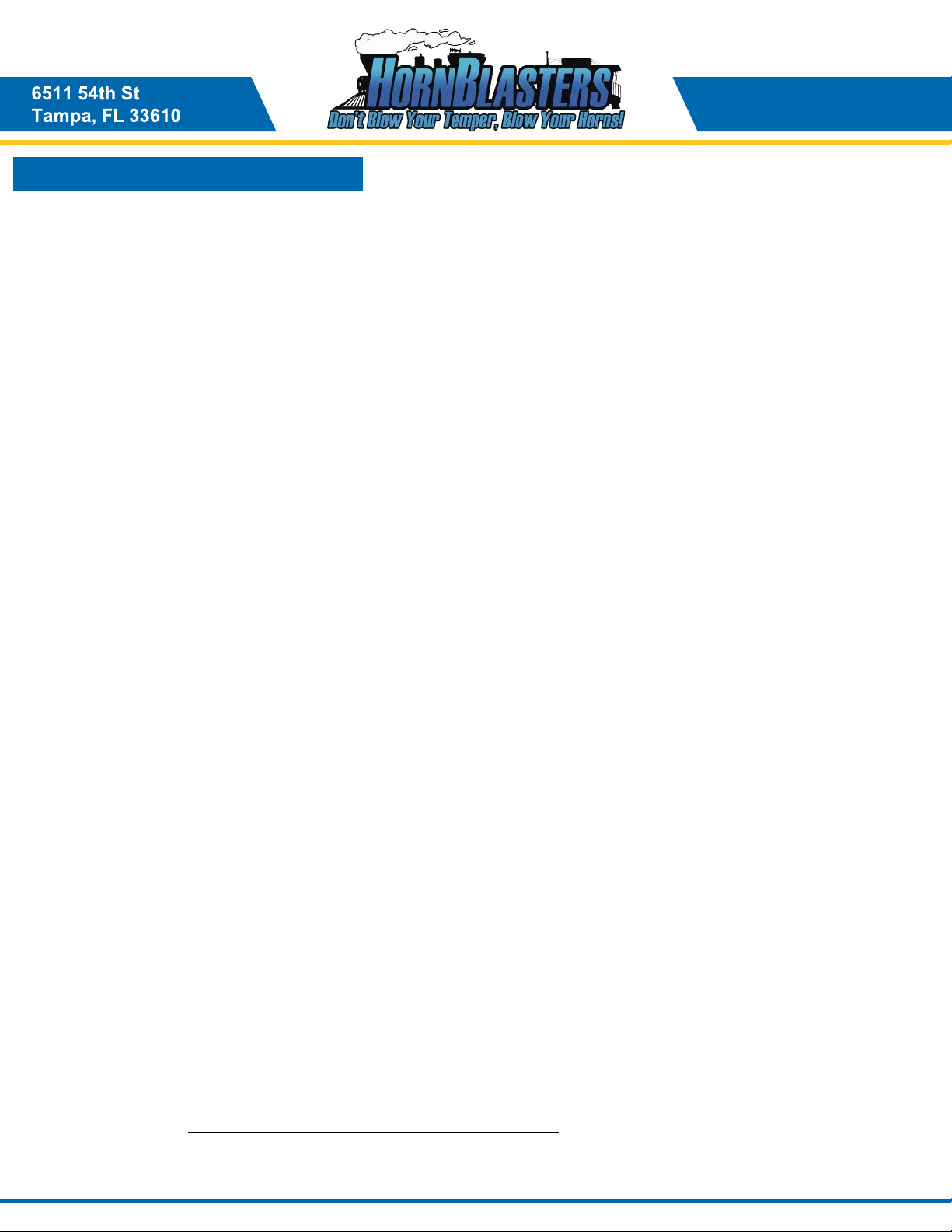

Using A Toggle Switch Instead of a Key Power Source

If you can't find a good key power source, you can use a toggle switch instead to manually stop the

compressor from running. To do this, locate the supplied toggle switch that came with your horn kit. Wire

one lead of the toggle switch to +12v power and take the opposite lead of the toggle switch to pin 86 on the

relay. When you flip the switch on, the relay will switch on and allow the compressor run. Wiring your kit

this way means that you MUST turn the switch off with the vehicle, otherwise the compressor could run

overnight and drain your battery.

6511 54th St

Tampa, FL 33610