2

1.0 General safety precautions

IMPORTANT – Carefully read the entire instruction

manual before mounting and commissioning.

Please keep these instructions in a safe place and

instruct all users in the function and operation of the

energy arm.

Installation and service should only be carried out after

studying section 4 thoroughly.

Avoid detatching any factory-mounted parts, since it

impedes the commissioning of the equipment.

All electrical installations must be carried out by an

authorised electrician.

1.1 Danger

It is potentially deadly to touch the wires under the

Yellow cover shield.

Use extreme caution.

1.2 Area of application

The GEOVENT Energy arm is used where power, point

extraction and compressed air is needed at a

workstation.

The energy arm is NOT for use is areas categorized as

ATEX zones. Use only ATEX approved material.

1.3 Handling

Use protective gloves when transporting and installing

the energy arm.

1.4 Technical data

Power outlet: 1x230V, 13A

Supply: 3x400V, 16A

Compressed air: 2 outlets,

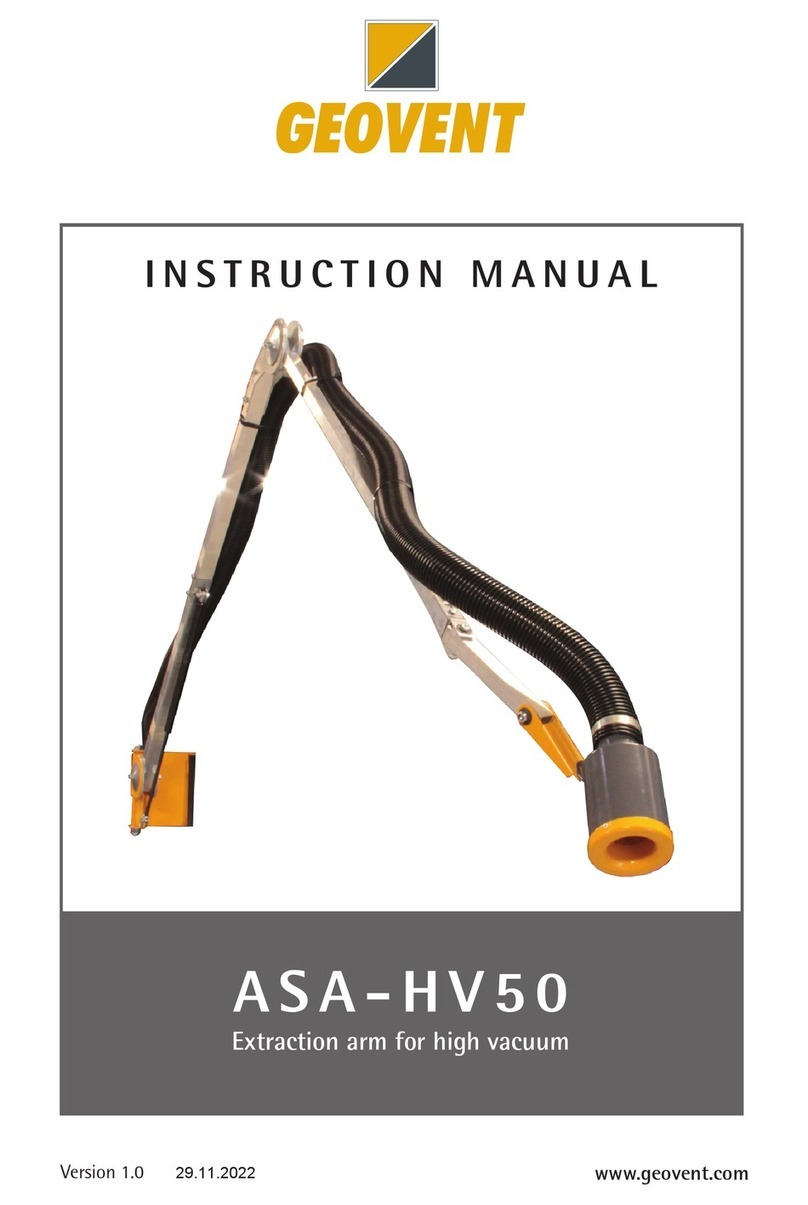

Extraction: High Vacuum with ø50 ap valve.

1.5 Construction

Wall console + arm: Painted steel, 50x100 prole, The

swivel joint of the console pivots up to 270°.

Protective box: Powdercoated, galvanized steel.

Suspension: Balancer and hose (GeoFlex P2A 1000)

for hose- and cables.

Hose for High Vacuum and cables are kept in the spiro-

duct on the arm.

2.0 Installation

The energy arm is supplied un-assembled. Depending

on the model it consists of one arm and spiro duct, one

protective box with outlets, one assembly kit with balan-

cer, bend with suspension and hose with hose clamps

and rubber bands for ducting.

Any ordered alterations will be stated on the order

conrmation/invoice.

Before mounting, please consider:

• Ample space for satisfactory use of the arm.

• Optimum height of installtion.

• Ducting and connections.

• First fasten the wall console of the arm on a

sturdy wall - e.g. a concrete wall.

• Mount arm on console.

• Fit spiro duct on the arm.

• Pass cables and hoses through spiroduct,

exible hose and bend.(Remember to attach

hose clamp and rubber band prior to this.)

• Connect cables and hoses to the satellite.

• Suspend the satellite.

Balancer

Satellite box

with outlets

Bend with

suspension

Support arm

Spiro duct

Table of content

1.0 General safety precautions . . . . . . . . . . . . . . . . . . 2

1.1 Danger ..................................2

1.2 Area of application .........................2

1.3 Handling ................................2

1.4 Technical data.............................2

1.5 Construction .............................2

2.0 Installation ...............................2

2.1 Power connection .........................3

3.0 User instruction............................3

4.0 Maintenance .............................3

5.0 Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.0 Declaration of conformity ....................4