1 Use 3

1.1 Intended use .................................................................. 3

1.2 User group..................................................................... 3

2 Safety 4

2.1 Symbols......................................................................... 4

2.2 Operational safety.......................................................... 4

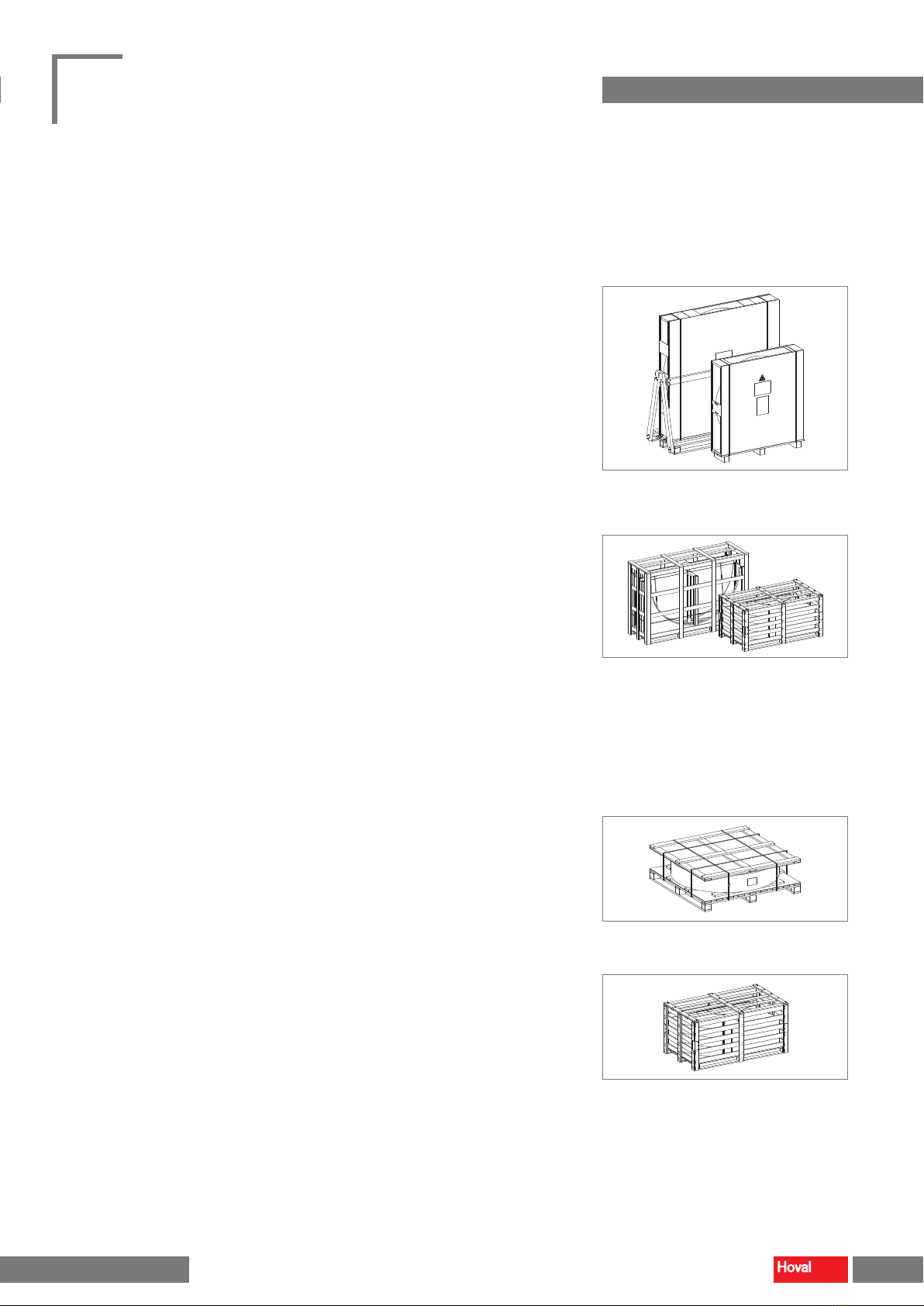

3 Delivery 5

3.1 Scope of delivery ........................................................... 5

3.2 Identication and test..................................................... 6

3.3 Storage .......................................................................... 6

4 Tools and aids 6

5 Lifting the exchanger 7

5.1 Lifting exchangers on pallets.......................................... 7

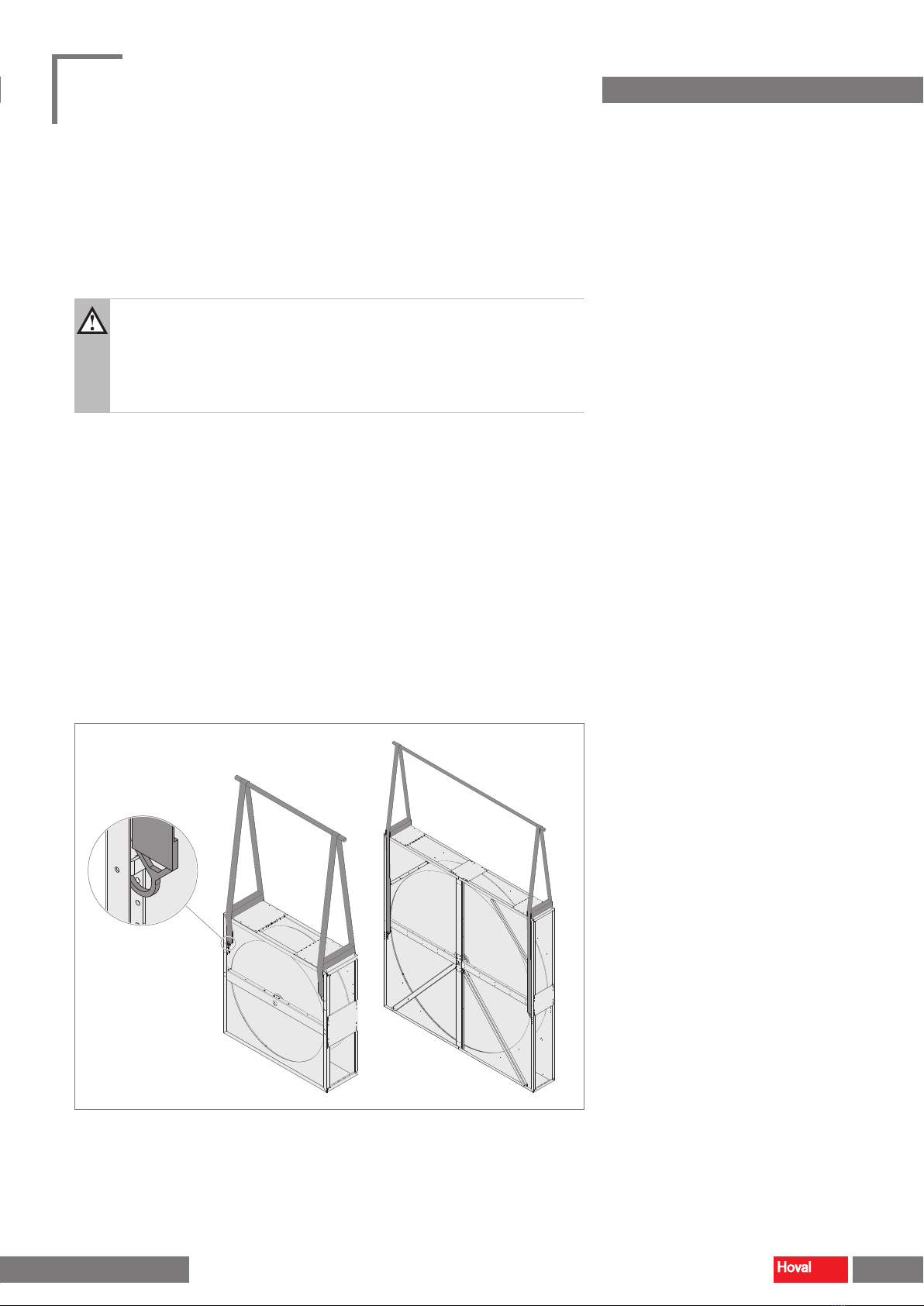

5.2 Lifting exchangers with SM casing................................. 7

5.3 Lifting exchangers with SP casing.................................. 8

5.4 Lifting exchangers with PR casing ................................. 9

5.5 Lifting wheels without casing........................................ 10

6 Installation of segmented exchangers 11

6.1 Casing...........................................................................11

6.2 Radial walls.................................................................. 14

6.3 Storage mass............................................................... 16

6.4 Purge sector ................................................................ 20

6.5 Seal ............................................................................. 22

6.6 Drive system ................................................................ 23

7 Installation in the air handling unit 26

7.1 Requirements for the installation site ........................... 26

7.2 Vertical installation ....................................................... 26

8 Electrical connection 27

9 Commissioning 28

9.1 Checklist ...................................................................... 28

9.2 Monitoring work after 2 weeks...................................... 28

10 Maintenance and repair 29

10.1 Maintenance schedule ............................................... 29

10.2 Cleaning..................................................................... 29

10.3 Spare parts ................................................................ 29

10.4 Replacement of the brush seal................................... 29

10.5 Replacement of the V-belt.......................................... 30

10.6 Repair ........................................................................ 30

2

Rotary heat exchangers

Instructions for installation, commissioning and maintenance

4 219 613-en-00 4 219 613-en-00

Content