0

h

cy

P

Y

4b

4

J

Model

4

12A

2-1.

INTRODUCTION.

SECTION

II

IN

STACLATIO

N

2-2. Tliis section contains instructions necessary for

installation

of

the Model 412AIAR

DC

Vacuum Tube

Voltmeter. Included are initial inspection procedures,

power and grounding requirements, installation

information, and instructions for repackaging for shipment.

2-3.

INITIAL INSPECTION.

2-4.

This

instrument was carefully inspected both

mechanically

and

electrically before shipment. It should be

free

of

mars or scratches, and in perfect electrical order

upon receipt.

To

confirm this, the instrument should be

inspected for physical damage

in

transit.

Also

test the

clcctrical

performance

of

tlic instrument, using the

procedure outlined in Paragraph

5-5.

If

there is damage or

deficiency, see tlic warranty on the inside front cover of

this manual.

2.5.

POWER

REQUIREMENTS.

2-6.

The Model 412AIAR can be operated from any

source

of

115

or

230

volts at

50

or

60

Hz.

The

115/230

V

slide switch

on

the rear panel selects the desired voltage.

Power dissipationis approximately

35

watts.

2-7.

G

R

0

U

N

D

I

NG

REQUl

R

EMENTS.

2-8.

To protect operating personnel, the National

Electrical Manufacturer’s Association

(NEMA)

recommends

that tltc instrument panel and cabinet

be

grounded. This

instrument is equipped with a threeconductor power cable

wluch, when plugged into an appropriate receptacle.

grounds the instrument. The offset pin

on

the connector is

tlie ground wire.

2-9.

To

preserve the protection feature when operating the

instrument from a twocontact outlet, use a threeprong

to

two-prong adapter and connect the green pigtail

on

the

adapter toground.

NOTE

Operating the Model 412A/AR without

grounding the third (power line ground)

wire

of

the power cable will result

in

a

zero offset

of

the meter and oscillation

of

the pointer.

2-1

0.

INSTA

1

LATlON.

Section

I1

2-1

I.

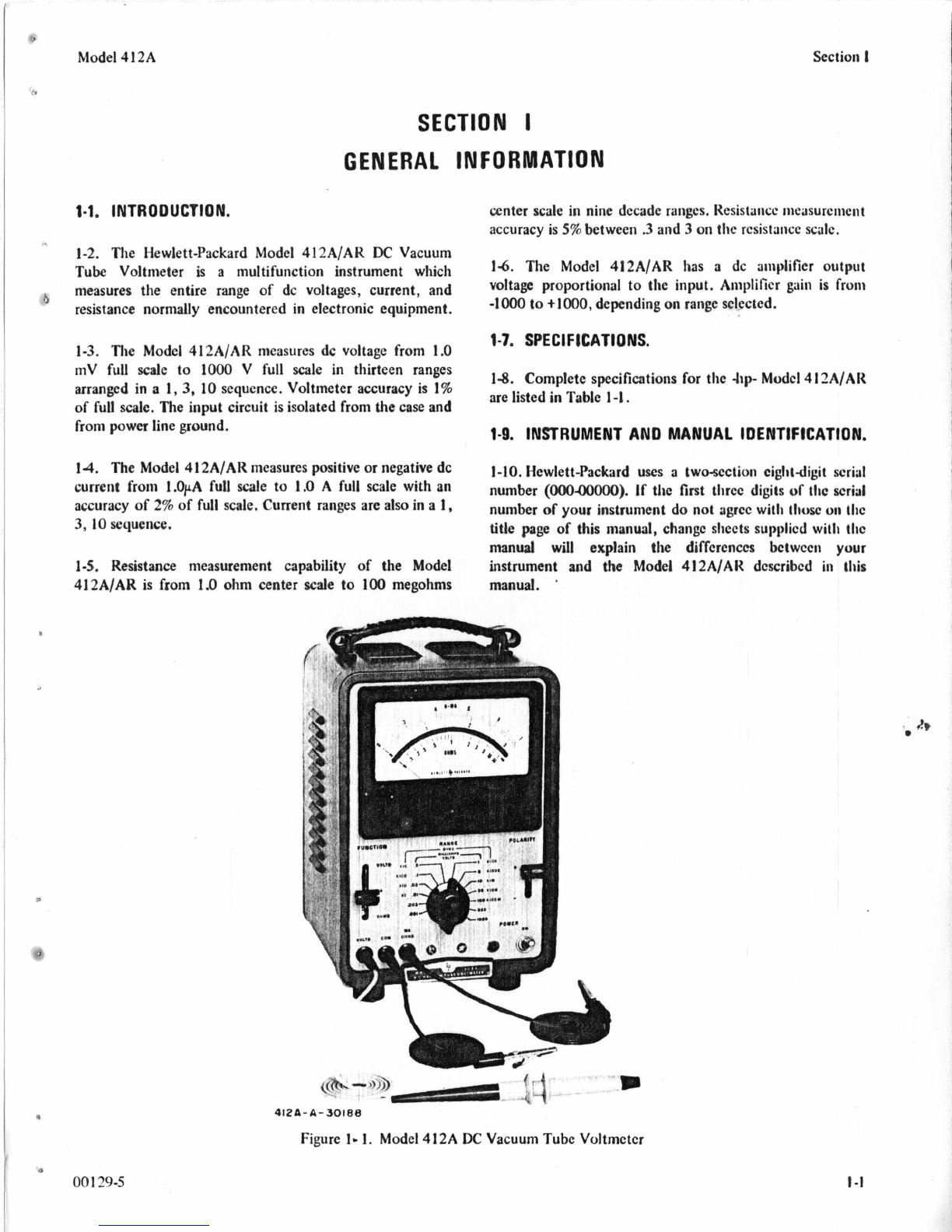

The Model 412A is intended

for

use

as

a

bcncli

instrument, having a top-mounted handle and rubbcr fcct.

2-12. The Model 412AR is intended for rack mounting.

Front panel height

is

5-7/32 inches.

2-13.

REPACKAGING

FOR

SHIPMENT.

2-14.

The following paragraphs contain

a

general guidc for

repackaging

of

tlie instrument. Rcfcr to Paragraph

2-15

if

the original container is

to

be

uscd;

2-16

if

it

is

not.

If

you

have any questions, contact your

local

-lip-

Salcs

and

Service Office. (SCCAppendix

B

for office locatiwis.)

NOTE

If

the instrumcnt is to be sliippcd

to

I

Icwlctt-i’ackard for scrvicc

or

repair.

attach a tag to tlic instrumcnt idcntifying

the owncr and indicating tlic scrvicc

or

repair

to

be accomplislicd. lncludc tlic

model number

of

tltc instrumcnt.

In

any

corrcspondcnce, identify tlic instrumcnt

by modcl numbcr, scrial numbcr prcfix,

and scrial numbcr.

2-15. Place the instrumcnt

in

original conhincr with

suitable packing material and

scat

wcll

with strong tapc

or

metal bands.

If

original containcr

is

not aviilablc, onc

CBR

be

purchased from your ncarcst

hp

Salcs

and

Scrvicc

Office.

2-16.lf original container

is

not to hc uscd, procccd

as

follows:

a. Wrap instrument

in

hcavy

papcr or plastic hcfurc

placing in an inncr containcr.

b.

Place packing material around a11

sidcs

of

instrumcnt and protcct panel facc

with

cardhturd

strips

.

c. Place instrument and inncr containcr

in

a hcavy

carton

or

wooden box and scal wcll with strong

tapc

or

metal hands.

d. Mark shipping containcr

“DI~LICATE

INSTIWMENT,”

“FRAGILE,” ctc.

00

1

29-5

2-1