Model 5254C Section III

SECTION III

OPERATION

3-1. INTRODUCTION.

3-2. The Model 5254C Frequency Converter increases

the range of an HP Electronic Counter to. 15 through

3. 0GHz (150 through 3000 MHz). As ageneral rule

to measure frequency, always start with the Mixing

Frequency Control below .2GHz and tune upward in

frequency to obtain first response and tune for a

maximum reading in the green portion of the meter

scale. The input frequency is the sum of the counter

reading and the dial frequency reading. This proce-

dure will be valid whether there are responses in 1,

2, or 3consecutive harmonic reference frequencies;

see Figure 3-1. If the input signal level to the con-

verter is high, the second, third and other harmonics

of this signal may be generated. Therefore, tuning

Mixing Frequency Control from the low end upward

will enable the input fundamental frequency to be de-

tected before its harmonics. In the 5254C, harmonics

of the reference-frequency signals are held to such a

low level that regardless of input signal level, their

mixing effects are not observable, avoiding possible

ambiguity. Figure 3-1 provides astep-by-step pro-

cedure to be used for measurement of frequencies from

.15 to 3. 0GHz (150 MHz to 3000 MHz). The only ex-

ception is if the first response occurs at •15 GHz or

.25 GHz. To avoid possible ambiguity in these cases,

start from above .45 GHz and tune downward in fre-

quency for the first response and subtract the counter

reading from the dial frequency for the frequency of

the input signal.

Note

If the input frequency is known approximately,

the Mixing Frequency Control can be set a

hundred megahertz below the input signal. Tune

up for the first response and add the counter

reading to the dial frequency.

3-3. CONTROLS AND INPUT.

3-4. GENERAL. The function of the front panel con-

trol, meter, connectors, and retaining screws are

discussed in Paragraphs 3-5 through 3-8.

3-5. INPUT CONNECTOR. Signal input, 50 ohms in-

put impedance, 50 mV (-13 dBm in 50 ohms) to 1V

rms (+13 dBm in 50 ohms) into Type Nfemale

connector.

3-6. MIXING FREQUENCY SELECTOR. Calibrated

from .2to 3. 0GHz (200 MHz to 3000 MHz), this con-

trol tunes the internal cavity to select aharmonic of

50 MHz to be heterodyned with the INPUT signal.

3-7. LEVEL INDICATOR METER. The meter circuit

continuously monitors the level of the difference fre-

quency output of the converter to the counter. When

meter reads in the green portion of its scale, INPUT

signal amplitude is adequate for accurate frequency

measurement.

3-8. AUX OUT CONNECTOR. The 1MHz to 50 MHz

video amplifier output appears at AUX OUT BNC type

connector.

3-9. MAXIMUM INPUT VOLTAGES.

3-10. Damage to the converter may result if an ac

signal greater than +20 dBm in 50 ohms (2.2 Vrms)

or adc voltage greater than 100V is applied to the

converter INPUT connector.

3-11. FREQUENCY MEASUREMENT WITH

AMPLITUDE LESS THAN 50 MV RMS.

3-12. The front panel level indicator meter indicates

in the green portion of its scale only when converter

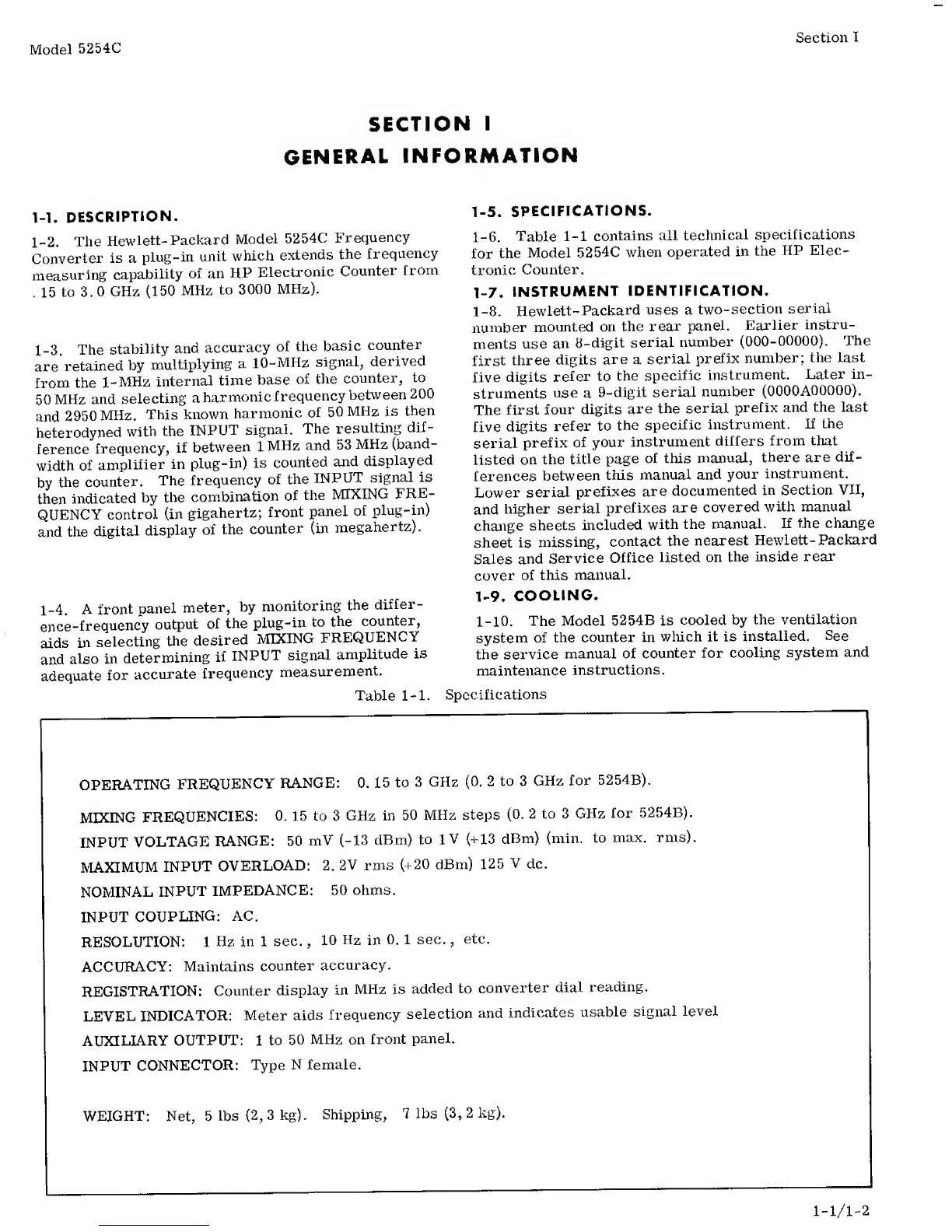

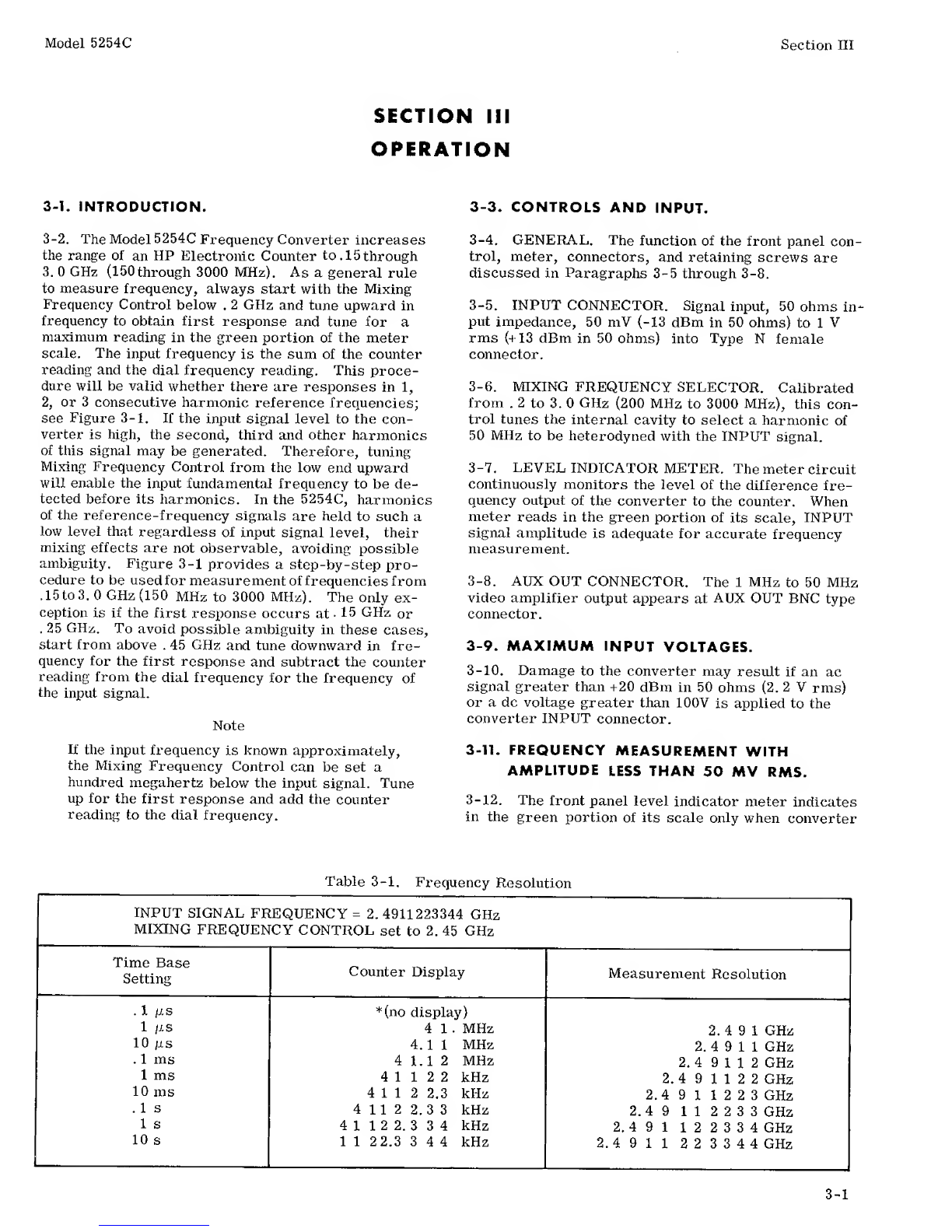

Table 3-1. Frequency Resolution

INPUT SIGNAL FREQUENCY =2.4911223344 GHz

MIXING FREQUENCY CONTROL set to 2. 45 GHz

Time Base

Setting Counter Display Measurement Resolution

.1 jl s*(no display)

1/IS 41.MHz 2. 491GHz

10 /is 4.11 MHz 2. 491 1 GHz

.1ms 41.1 2MHz 2. 49112 GHz

1ms 41122 kHz 2. 491122GHz

10 ms 41 1 22.3 kHz 2.4 911223GHz

.1s41122.3 3kHz 2. 491 1 2 2 33GHz

1s41122. 334kHz 2. 491 122334 GHz

10 s1 1 22.3 344kHz 2.491 1223344 GHz

3-1