I

554A

Model

654A Section

II

SECTION

II

INSTALLATION

2-1.

INTRODUCTION.

2-2.

This section contains information and instructions

necessary for installing and shipping the Model 654A Test

Oscillator. Included are initial inspection procedures, power

and grounding requirements, environmental information,

installation instructions and instructions for repackaging for

shipment.

2·3.

INITIAL

INSPECTION.

2-4.

This instrument

was

carefully inspected both

mechanically and electrically before shipment. It should be

physically free

of

mars or scratches and

in

perfect electrical

order upon receipt. To confirm this, the instrument should

be

inspected for physical damage

in

transi t. Also. check for

supplied accessories, and test the electrical performance

of

the instrument using the proced

ure

outlined

in

Section

Vof

this manual. If there

is

damage or deficiency, see the

warranty on

Page

ii

of

this manual.

2·5.

POWER

REQUIREMENTS.

kHz, 2·6. This instrument

will

operate from either 115 or

230 V ac,

48

Hz

to 66

Hz.

The instrument can easily be

the position

of

the slide switch located

on

the rear panel, so

that the designation appearing on the switch matches the

nominal voltage

of

the power source.

the

o

dB

than

Be/ore applying primary power to the 654A

be slire it is set for the proper

fine

voltage

as

olltlined

in

Paragraph

3-8.

Inda-

2-7.

Power

Cords.

Inda-

2-8.

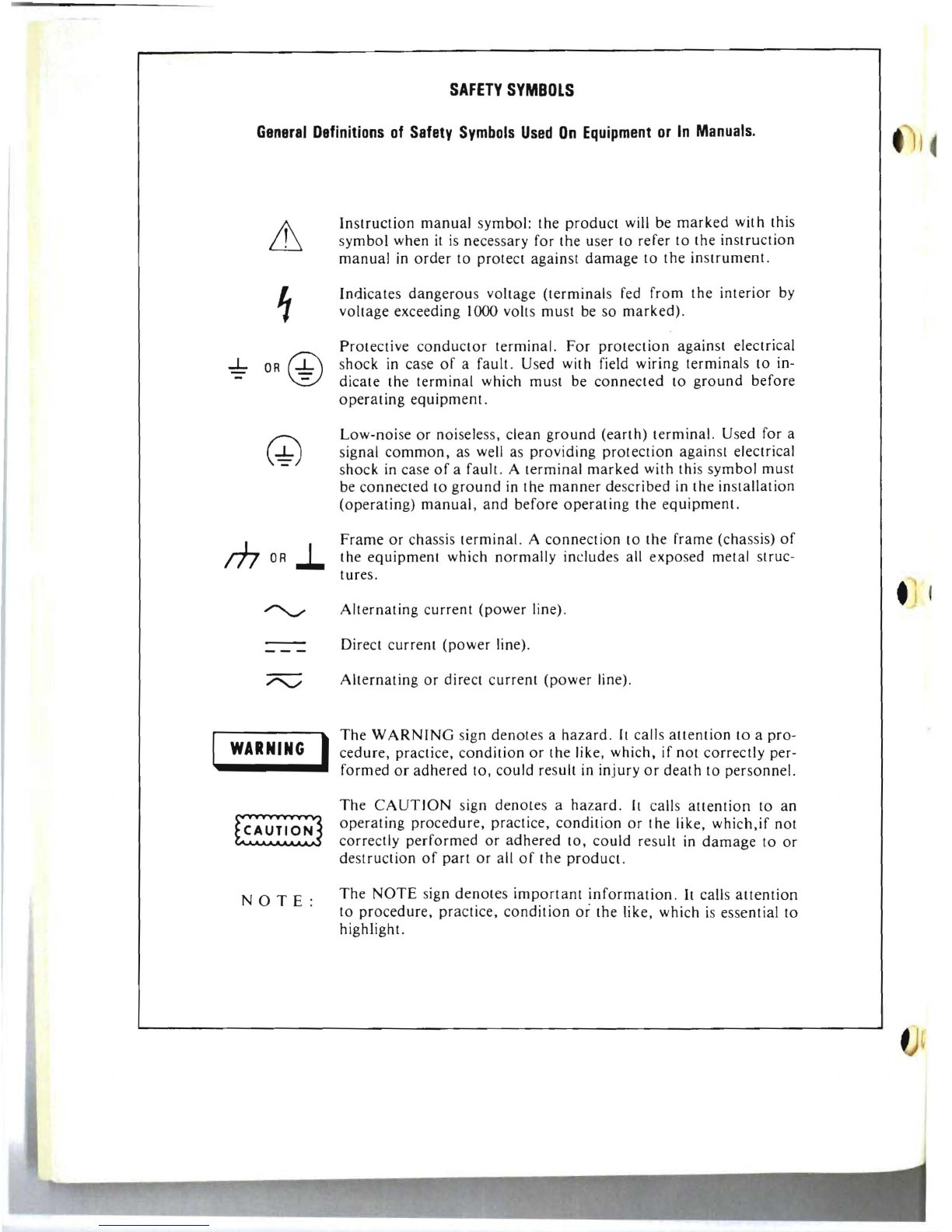

Figure

2-J

illustrates the standard power plug config-

urations that are

used

throughout the United States and

in

tput. other countries. The

-hp-

part number directly below each

drawing

is

the part number for a 654A power cord

equipped with a power plug

of

1hat configuration. If the

appropriate power cord

is

not included with the instru-

ment , notify the nearest -hp- Sales and Service Office and a

replacement cord will be provided.

2-9.

GROUNDING

REQUIREMENTS.

2-10.

To protect operating personnel, the National Electri-

cal

Manufacturer's Association (NEMA) recommends that

the instrument panel and cabinet

be

grounded. The Model

654A

is

equipped with a three-conductor power cord

which , when plugged into an appropriate receptacle,

grounds the instrument. The offset pin

on

the power plug

is

the ground connection.

8120-1351

8120-1369

8120-1689

STO·8-419~

'UL

LISTED FOR

USE

IN THE UNITED STATES

OF

AMERICA

Figure 2-1.

Power

Cords.

2-11.

INSTALLATION.

2-12. This instrument

is

fully transistorized: therefore no

special cooling

is

required. However, the instrument should

not

be

operated where the ambient temperature

is

outside

the limits specifed

in

Table 1·2.

2-13.

RACK/BENCH

INSTALLATION.

2-14. This instrument

is

initially shipped

as

a bench-type

instrument (unless ordered specifically

as

a rack-type) with

plastic feet and tilt stand

in

place. Conversion

to

a rack-

mounted inst rument can

be

accomplished

by

using the

rack-mounting kit and instruction furnished with

YOUl

inst rumen t.

2-15_

REPACKAGING

FOR

SHIPMENT.

2-16. The following

is

a general guide for repackaging for

shipment. If you have any question, contact your local

-hp-

Sales and Service Office_(See Appendix

at

the back

of

this

manual for office location.)

NOTE

If

the instrument is

to

be shipped to Hewlett-

Packard

for

service or repair, attach a

tag

to

the instrument identifying the owner and

indicating the service

or

repair to be accom-

plished; include the model number and full

serial

number

of

the instrument. In any corre-

spondence, identify the instrument

by

model

number

and serial number.

a.

Place instrument

in

original container if avail-

able. If original container

is

not available, a suit-

able one can

be

purchased from your nearest -hp-

Sales and Service Office.

2-1