proprietary and confidential page 2 of 3

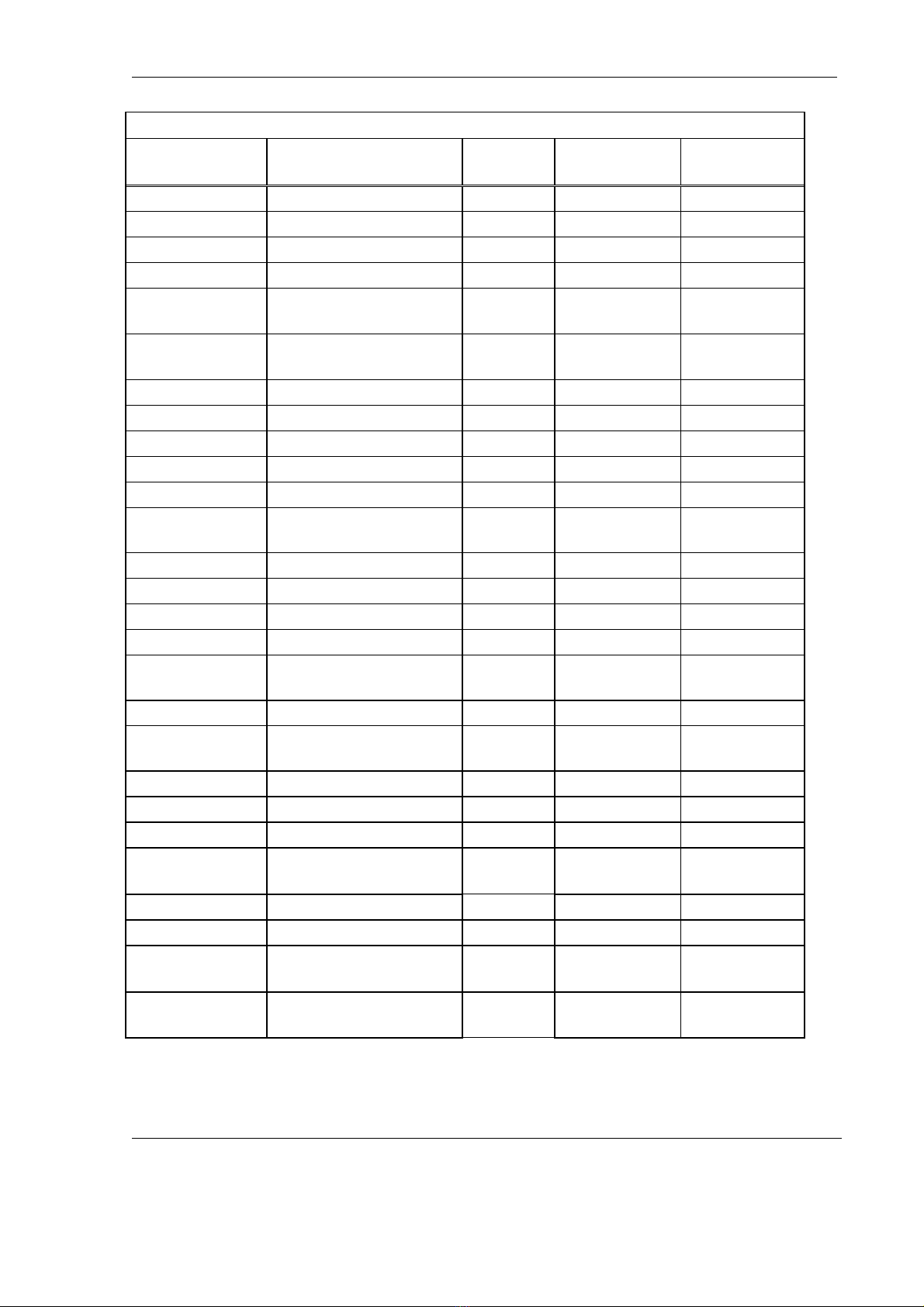

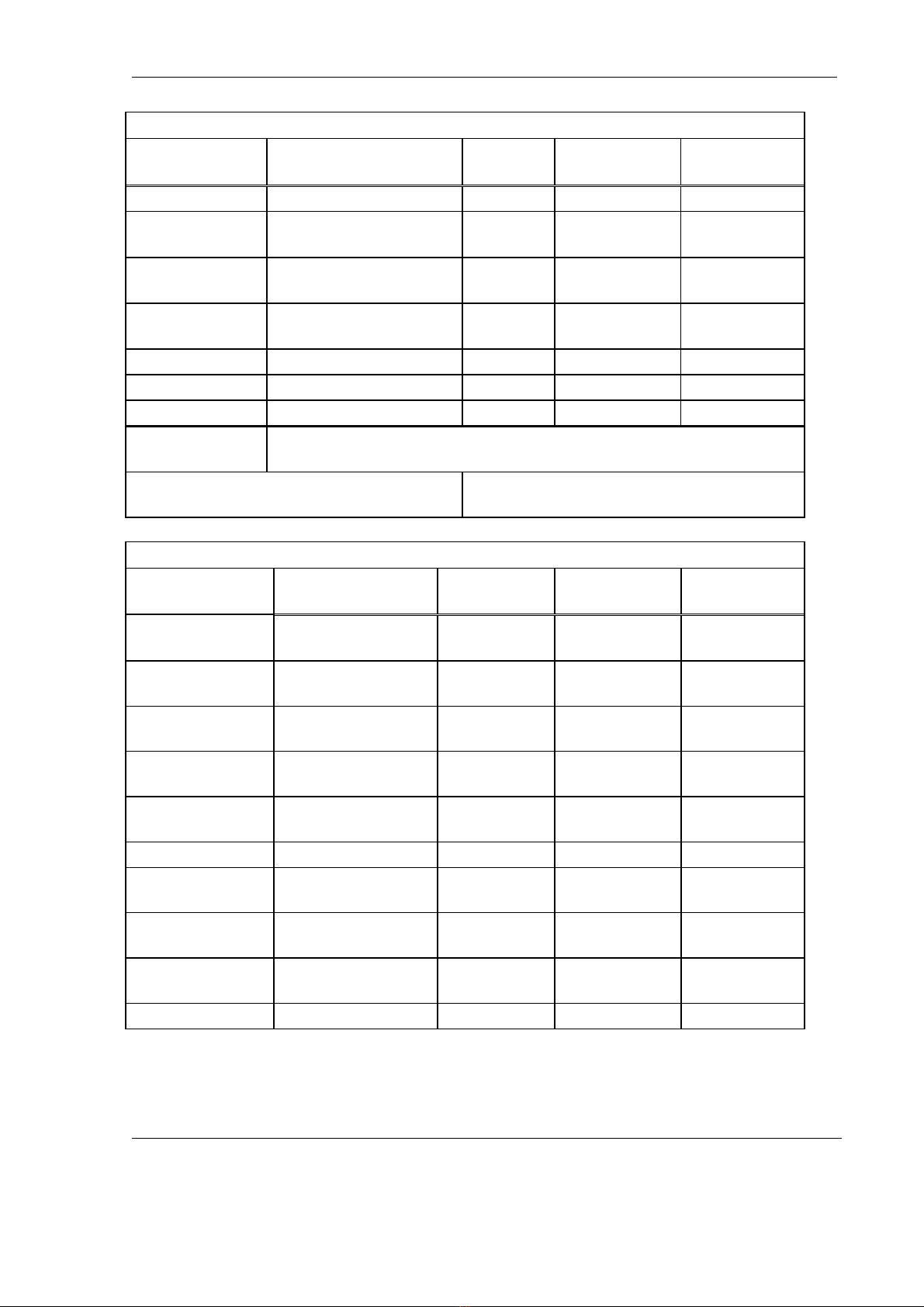

•hp x2100 Pentium IV PC with software version 5.0 (P/N

EAS-1471-51), for press S/N 11200803 and up:

The software includes hp indigo RIP version 5.0, hp indigo yours truly

designer version 5.0, and hp indigo yours truly express version 5.0.

The software currently supports IndigoServe version 1.0.

The HP 2100 computer does not have an ISA slot; Therefore the

POPCORN cannot be mounted on this computer.

An EPU (the replacement of the UCB) was designed to allow the

mounting of a POPI II (the replacement of POPCORN) in the press.

The POPI II communicates with the computer via the on board Ethernet

port on the motherboard.

The VCORN I does not fit in the new HP 2100 computer. A new

modified VCORN I was designed to fit in the computer.

The hp indigo press arrives with a new hp monitor. This monitor includes

a new external power supply.

An ORB media 2.2 GB replaces the old Jaz drive.

For more details Refer to T/N #595

•1 HP vacuum pump motor (P/N MMA-0101-05):

This improvement will eliminate overheating of the vacuum pump motor.

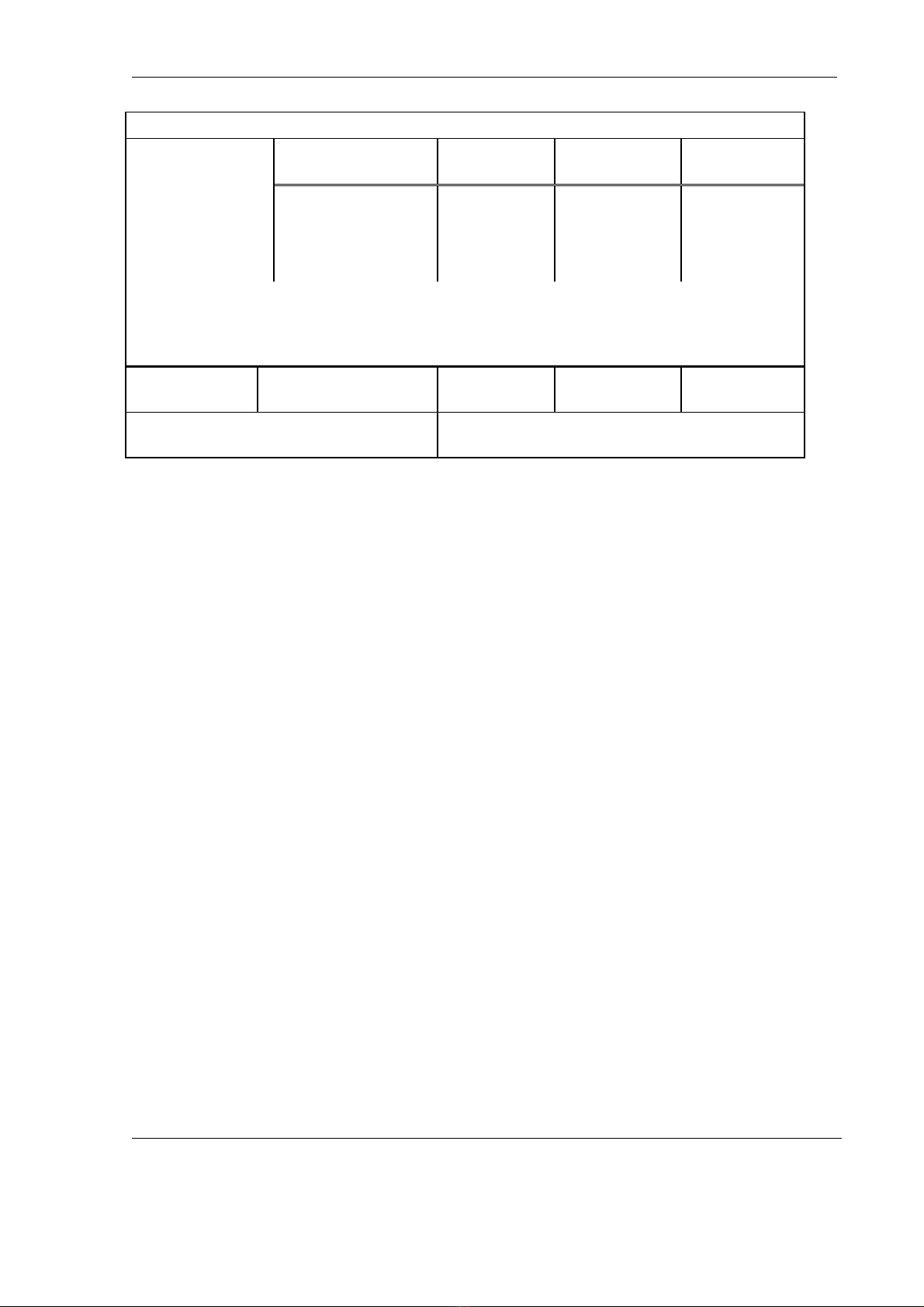

•New pulley for 60HZ presses:

The new vacuum pump pulley is part of the accessory kit and will be

installed in presses operating at 60Hz frequency. This pulley is

compatible to 60 Hz cycle and enable the vacuum pump motor to work

efficiently. This kit should be discarded in any other case. Refer to the

attached document for the installation procedure.

3. Instructions

The following are press installation important notes:

•The new vacuum pump pulley installation kit (P/N MKT-0102-01) should

be used in presses operating at 60Hz frequency.

•The HP monitor is supplied with an external power supply that should be

installed during the press installation.

4. Prerequisites

N/A