Model 182C General Information

SECTION I

GENERAL INFORMATION

1-1. INTRODUCTION.

1-2. This manual provides operating and servicing infor-

mation for the Hewlett-Packard Model 182C Oscilloscope.

The manual is divided into eight sections, each covering

aspecific topic or aspect of the instrument. All schematics

are located at the rear of the manual and can be unfolded

and used for reference while reading any part of the

manual

1-3. This section contains complete instrument specifi

cations {Table 1-1), adescription of features, warranty in-

formation, data for manual and instrument identification,

and information regarding accessories available for use

with the instrument. Table 1-2 lists and describes the

abbreviations used in this manual.

1-4. INSTRUMENT DESCRIPTION.

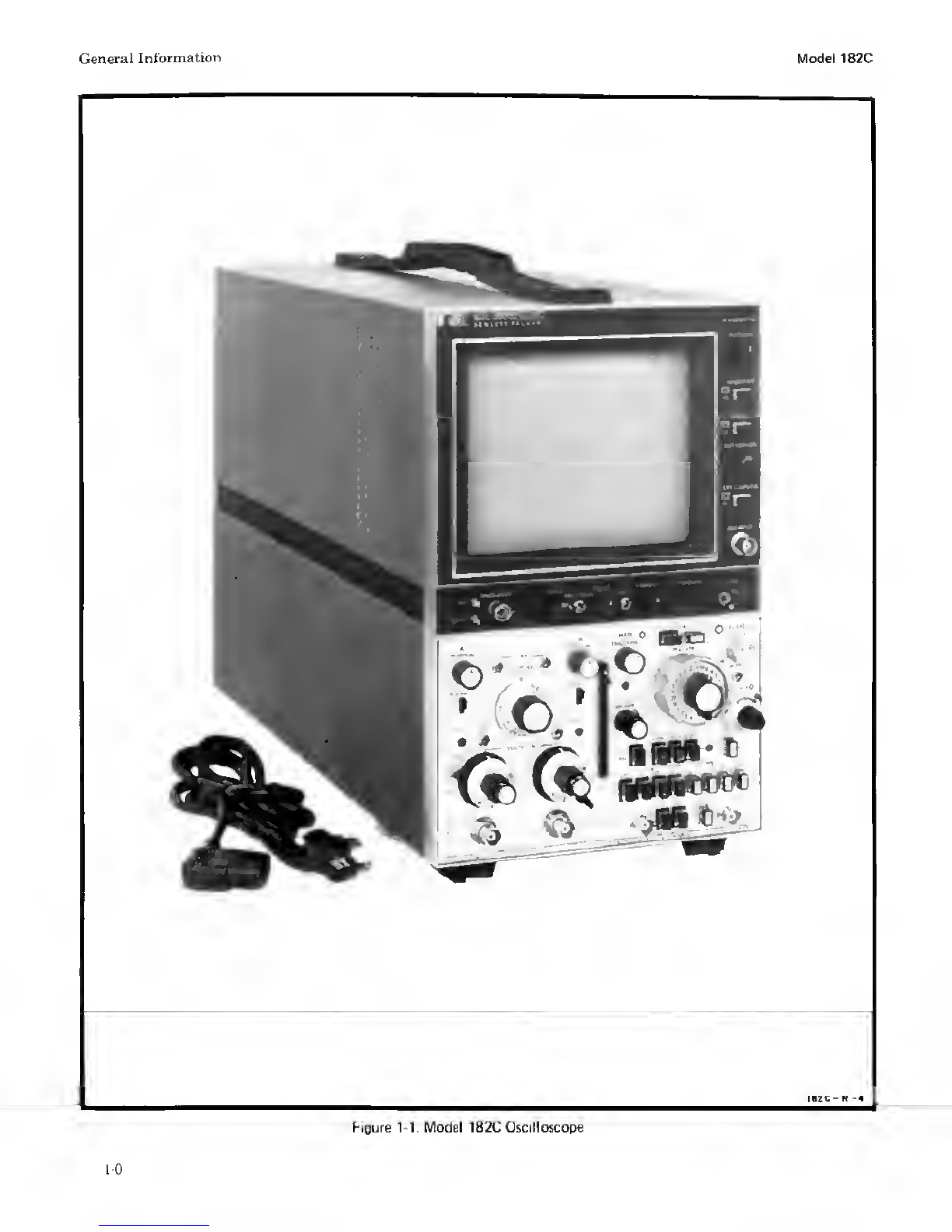

1-5. The Model 182C (Figure 1-1) is asolid-state, light-

weight laboratory and general-purpose oscilloscope with

plug-in capabilities. It is designed to display complex high

frequency waveforms and to measure alternating- and

direct-current voltages. Complete specifications are given

in Table 1-1.

1-6. The Model 182C is acabinet type instrument with a

built-in tilt stand, convenient carrying harrdle on top, and

feet mounted on both bottom and rear for either bench or

upright operation. Controls are arranged and located to

simplify operation.

1-7. For minimum size and weight with maximum reli-

ability. the Model 182C has solid-state circuitry through-

out except for the CRT. Power consumption, with plug ins,

is less than 120 watts at normal line voltage. The instru-

ment is convection cooled and designed to operate within

specifications at temperatures between 0° Cand 55° C

with up to 95% relative humidity at 40° C.

1-8. Alt power supplies, adual output calibrator, ahori-

zontal amplifier, agate amplifier and the CRT are

contained in this instrument. Operation at either 115V or

230V ac is selectable by aswitch located on the rear panel

of the oscilloscope. Located on the rear panel are

connectors for main and delayed gate, and main and

delayed sweep output signals. Connection for input of an

external signal for intensity modulation (Z-axis input) is

provided at the rear panel. An input signal of approx-

imately -I-2V having apulse width of greater than about

50 ns will blank atrace of normal intensity.

1-9. The Model 182C is designed to operate with a

number of different plug-in vertical amplifiers and time

bases. Presently available plug-ins provide awide choice

of operating capabilities such as wide bandwidth, sensi-

tivities, dual or four-channel operation, single or delayed

sweeps, sampling and time-domain reflectometer oper-

ation.

1-10. Modular type construction has been used through-

out the instrument. This makes it easy and simple to

remove units for quick maintenance. Assemblies are

constructed with interconnecting plugs and jacks and

each assembly can be removed without unsoldering

connections.

1-11. Acalibrator provides asquare-wave signal of

approximately 1kHz with arisetime of less than 3fxsec.

The calibrator output is available at the front panel at

amplitudes of 250 mV and 10V p-p with an accuracy

of ±1%. The signal may be used to check horizontal and

vertical deflection factors and to compensate divider

probes.

1-12. The oscilloscope horizontal amplifier accepts sweep

signals from the time base plug-in or an external signal.

Bandwidth is dc to 5MHz. dc-coupled, and 5Hz to 5MHz

with capacitive coupling. Two deflection factor ranges are

front panel selectable: 1V/div (XI), and 0.1 V/div ±5%

(X10). In addition, avernier control provides continuous

adjustment between ranges, The maximum external input

level is 3(X) Vdc, ac-coupled. with adynamic range of

+20V.

1-13. Abeam finder pushbutton control assists the oper-

ator in rapidly bringing adisplaced beam on screen. Its

use increases intensity and reduces vertical and horizontal

amplifier gain to quickly locate trace position.

1-14. CATHODE-RAY TUBE.

1-15. The Model 182C uses apost-accelerator aluminized

CRT with alarge eight by ten division display area of

133 cm^. Each division is 1.29 cm with 0.2-div sub-

divisions provided on the major axes. The graticule is

internal to the CRT, eliminating display parallax. Option

01 1instruments are provided with aP11 phosphor CRT.

The display intensity will not Increase when FIND BEAM

is depressed. This prevents phosphor burn.

1-16. The standard CRT supplied with this instrument

has aP31 aluminized phosphor, P2. P7 and P1 1phosphors

are also available as options.

1-1