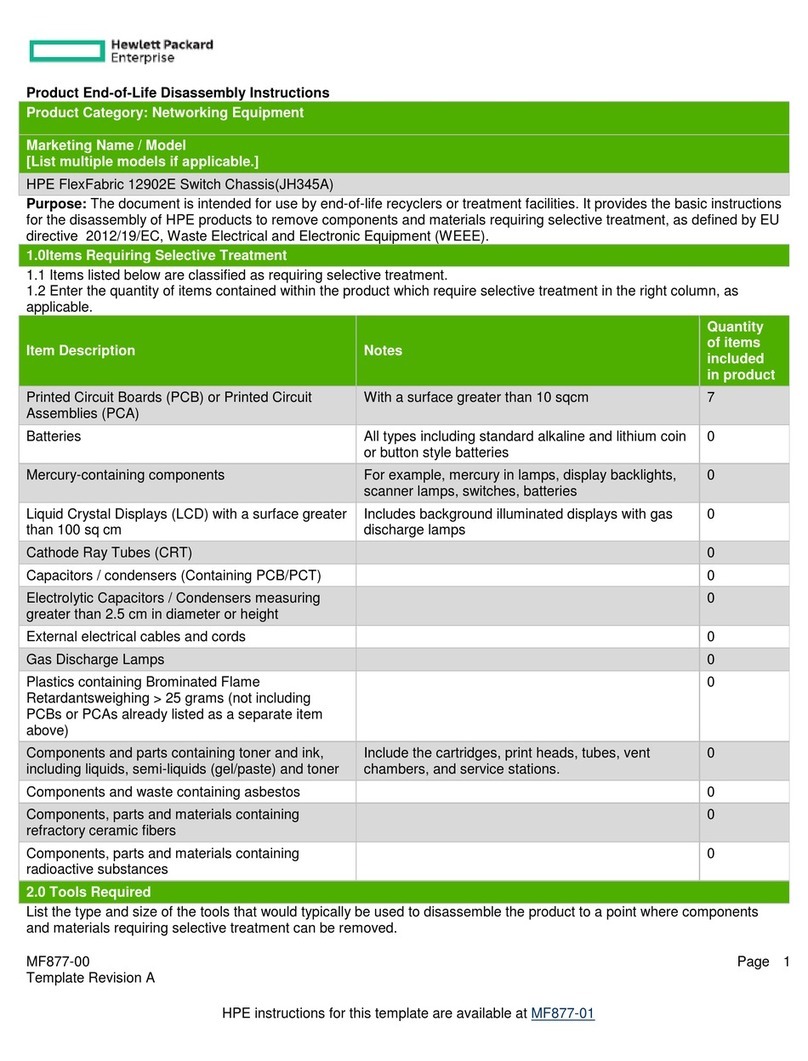

MF877-00 Page 3

Template Revision A

HPE instructions for this template are available at MF877-01

8. Remove the vertical busbar

1. Using a #2 screwdriver, remove the 8 screws attaching the top and bottom vertical busbar retainer.

2. Using a #6 nut spinner screwdriver, remove the nuts and washers attaching the cable on the vertical busbar.

3. Remove the vertical busbar and retainer.

9. Remove the busbar assembly

1. Using a #2 screwdriver, remove the 6 screws attaching the right and left busbar retainer.

2. Remove the busbar assembly and retainer.

3. Using a #2 screwdriver, remove the 6 nylon screws attaching the busbar assembly.

4. Separate the busbar assembly into two busbar and one mylar.

10. Remove the backplane cable and PDU cable

1. Using a #6 nut spinner screwdriver, remove the 2 nuts attaching the cable.

2. Remove the washers.

3. Repeat for the other 7 backplane cables.

4. Remove the two PDU cables.

11. Remove the whisper cable

1. Using a torx screwdriver, loose the 20 screws attaching the whisper cable.

2. Remove the whisper cable.

3. Repeat for the other whisper cable.

12. Separate the whisper cable

1. Using a #2 screwdriver, remove the 34 screws attaching the whisper cable.

2. Using a 5mm nut spinner screwdriver, remove the 7 spacers attaching the whisper cable.

3. Separate the whisper cable into 10 brackets,10 blocks ,34 screws,7spacers and 4 cables.

4. Repeat for the other whisper cable.

13. Remove the backplane

1. Using a #2 screwdriver, remove the 18 screws attaching the backplane.

2. Remove the backplane.

3. Repeat for the other backplane.

14. Remove the side cover

1. Using a #1 screwdriver, remove the 8 screws attaching the side cover.

2. Remove the side cover.

3. Repeat for the other three side cover.

15. Remove the top cover

1. Using a #1 screwdriver, remove the 2 screws attaching the top cover inside the chassis.

2. Using a #1 screwdriver, remove the 42 screws around the top cover outside the chassis.

3. Remove the top cover.