Page 2 of 14

B15

• Pen / Marker • Die Grinder & multi tool • Soapy water solution

• Centre Punch • Masking Tape • Allen Key set (Metric)

• Drill & Drill bits • Scissors & Knife

• Phillips head screwdriver • Ruler

• Caulking Gun • Spanner & Socket

• Silicon - Non Acetic • Tape measure

• Read Instructions fully before commencing installation.

• Clean Tonneau Cover with a mild detergent and water solution

• Do not use abrasive cleaners or solvents

• Refer to manufactures instructions applicable to power drill.

• Protect Tub floor against scratches during installation process.

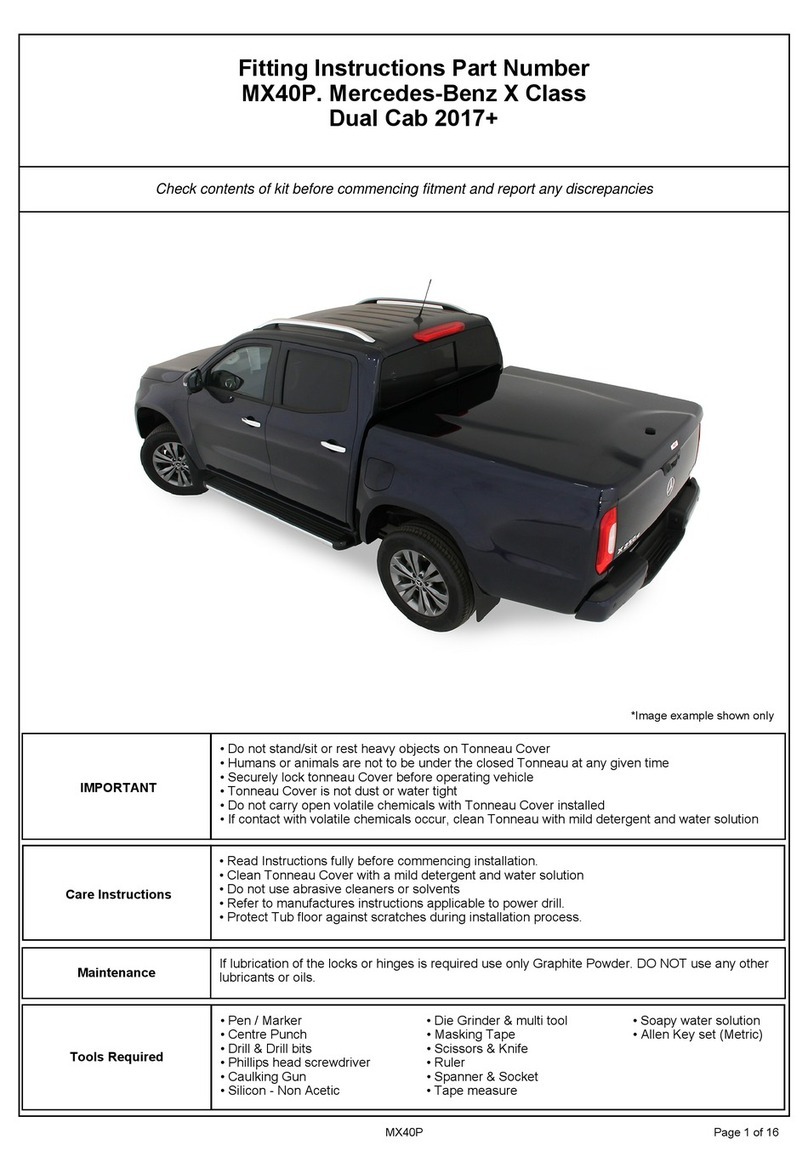

Check contents of kit before commencing fitment and report any discrepancies

Fitting Instructions Part Number B15

Mazda BT-50 Dual Cab 2011+

To suit Sports Bars

If lubrication of the locks or hinges is required use only Graphite Powder. DO NOT use any other

lubricants or oils.

• Do not stand/sit or rest heavy objects on Tonneau Cover

• Humans or animals are not to be under the closed Tonneau at any given time

• Securely lock tonneau Cover before operating vehicle

• Tonneau Cover is not dust or water tight

• Do not carry open volatile chemicals with Tonneau Cover installed

• If contact with volatile chemicals occur, clean Tonneau with mild detergent and water solution

Tools Required

Maintenance

Care Instructions

IMPORTANT

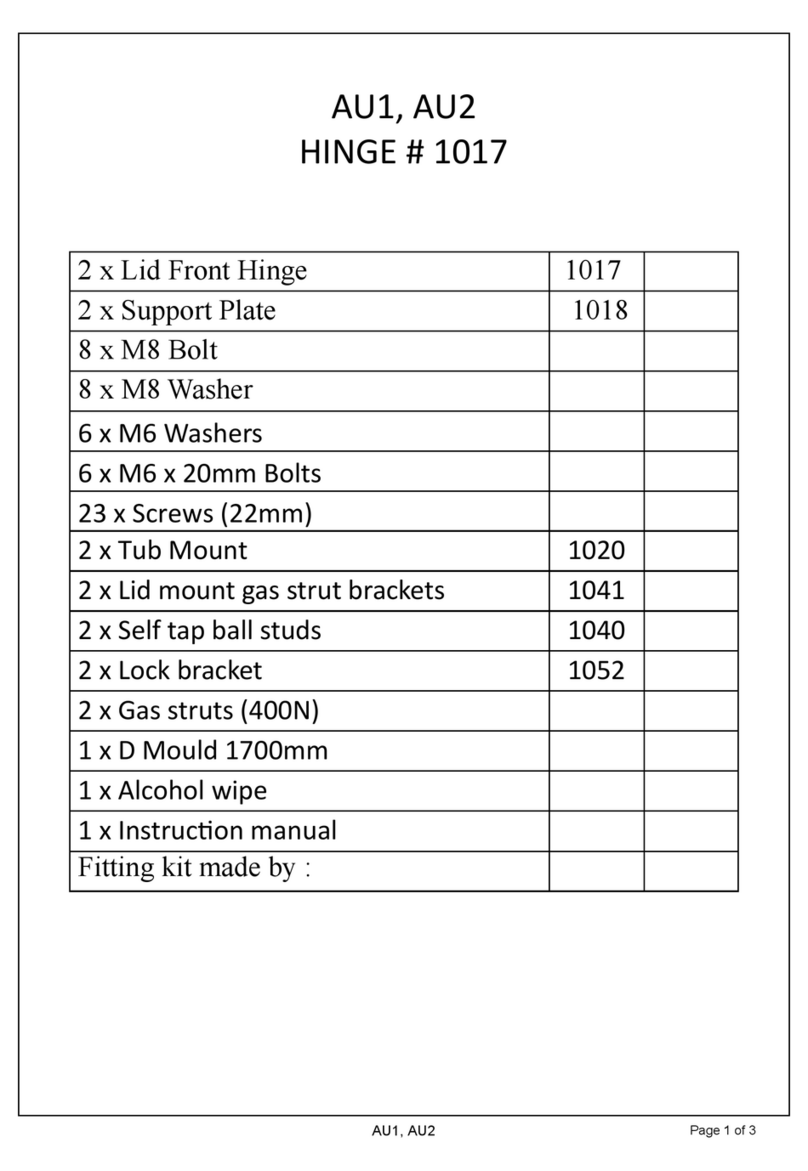

Parts List Qty Pre-Fitted

Hard Tonneau Cover 1

Infill Panel 2

Gas Struts (250N) 2

Front Hinge 2

Hinge Support Plate 2

M8 Washer 8

M8 Bolt 8

Lock Bracket 2

Self Drilling Screw 13

Lid Strut Bracket 2

M6 Bolt 6

M6 Washer 6

Front Body attach bracket 2

Lock Set 2

Tonneau corner pieces 2

Cleanseal 1

*Image example shown only