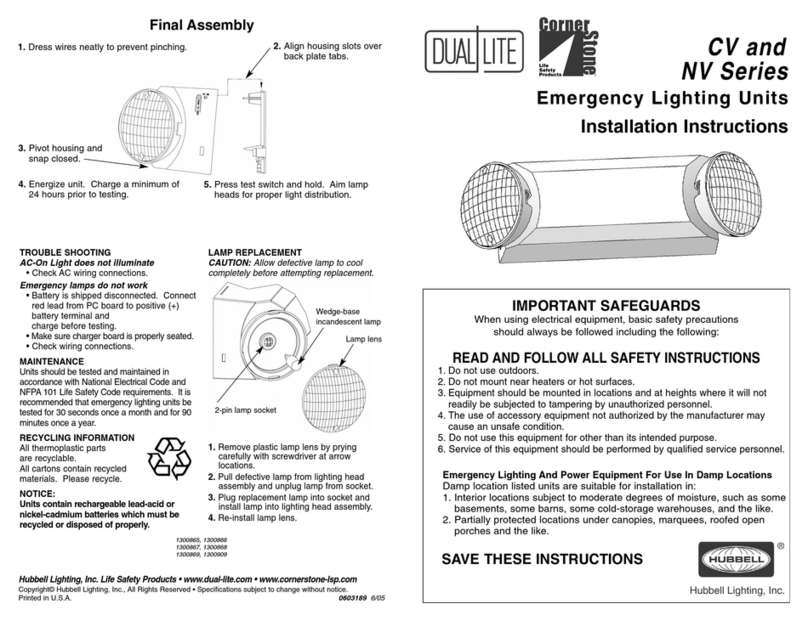

Cover Retaining

Screw

“AC-ON” LED

Test Button

GENERAL INSTRUCTIONS

This unit is designed for surface mounting on a wall or other sold surface (building support structure, column, etc.) using the

fourholesprovidedonthehousingmountingnges.Unitmustbemountedhighenoughtomaximizeilluminatedareaunder

anticipated conditions of use. Be sure to allow ample clearance for mounting and aiming the lighting heads.

Provideeachunitwithasingleunswitchedpowersupplyfroma120or277VACbranchcircuitusedfornormallightinginthesame

area. The wiring should be permanent installation, using appropriate size wire.

Note: De-energize AC circuit to unit during initial installation, and during servicing or relamping operations.

PLACING THE UNIT IN SERVICE

1. Fasten enclosure to wall surface using appropriate hardware (not provided).

2. Removetheve(5)coverretainingscrewsandopenunit.

3. Connect remote lamps (if used) to blue (+, fused) and yellow (–) leads (Fig. 1).

4. Connect120or277VACinputconnectionstotransformer(Fig.1).Connectgreenwiretobuildingground.

Note: insulate the unused transformer lead to prevent potential shock hazard.

UNITS SUPPLIED WITH LEAD-CALCIUM BATTERIES

5. Determineproperbatteryandwiringconguration(Seeinsidecoverlabelforbatteryandwirecongurations).

6. Connect positive (+, red) and negative (–, yellow) battery harness leads from printed circuit board to corresponding battery

terminals(Seeinsidecoverlabelforbatteryandwirecongurations).

7. Check all wiring for loose or missing connections.

8. Replace cover. Tighten retaining screws. Adjust lighting heads to desired position.

9. EnergizeunitwithACpower.Pressandholdthe“TEST”button(seeFig.1for“TEST”buttonlocation)toconrm

illuminationandproperaimingofemergencylamps.(“ACON”indicatorLEDshouldgooff).Releasethe“TEST”button;

emergencylampsshouldextinguish.Normaloperationbegins.

10. NormalOperation:withpowersupplied,“ACON”LEDindicatorisilluminatedandemergencylampsareoff.

ROUTINE TEST CYCLING

1. Everythree(3)months:Iftherehasbeennopowerfailure,pressandholdthe“TEST”buttonforatleastthirty(30)seconds

to conrmemergencylampoperation.Release“TEST”buttontoreturntobatterychargingmode.

2. Onceayear:Performafullbatteryconditioningcyclebyde-energizingtheACcircuittowhichtheunitisconnected,and

allow the unit to operate for ninety (90) minutes on battery power. Following successful test, energize AC circuit to begin

battery charging cycle.

REPLACING EMERGENCY LAMPS AND BATTERIES

General

1. De-energize the AC power supply to the unit.

2. Remove cover screws and open unit.

3. Disconnect positive (+, red) battery lead.

• Replacing Unit Emergency Lamp • Replacing Unit Battery

1. Remove diffuser lens from 1. Remove defective battery. Recycle responsibly.

lamp housing by prying lens Replace with genuine Dual-Lite battery.

adjacent to tab slot (see Fig.2) 2. Placenewbatteryinenclosure.Make

2. Remove and replace lamp. connections following steps outlined above.

(refer to unit product label 3. Test unit.

forspeciclamptype)

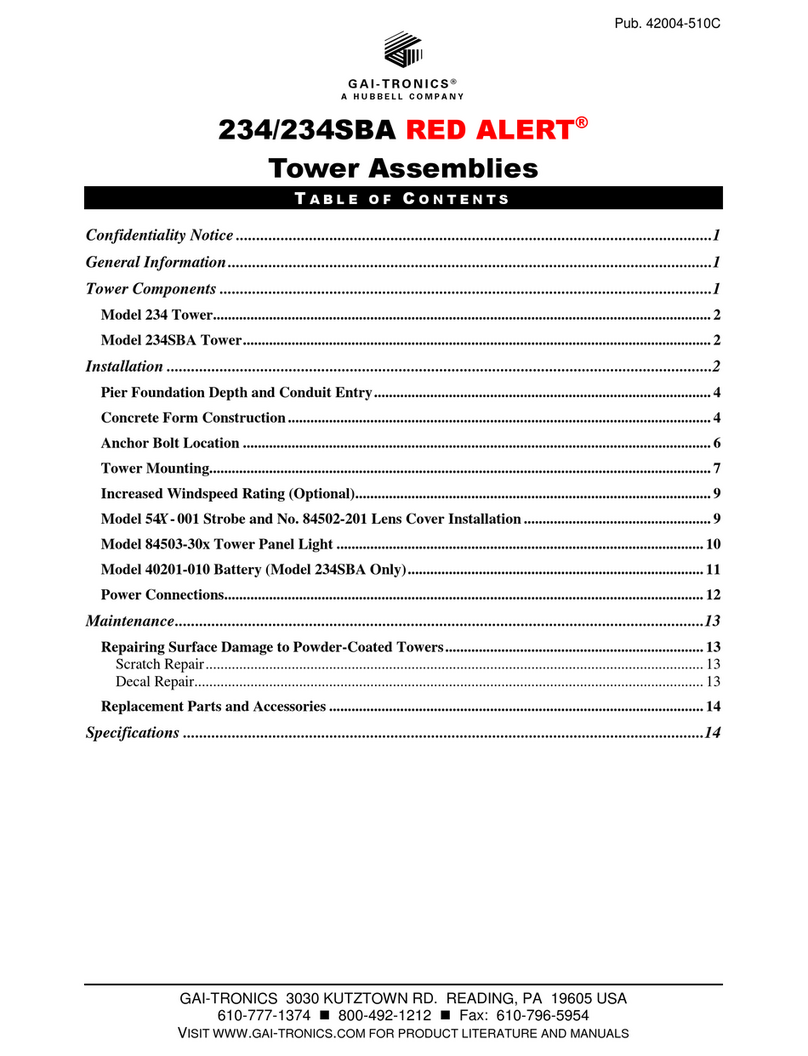

Instruction Label

Battery Location and Wire Connections

Yellow Negative (–)

Battery Lead Red Positive (+)

Battery Lead Remote DC Lamps

Positive (+) Lead with

“On-Board” Fuse

Remote DC Lamps

Negative (–) Lead

Transformer Ground

Wire (Green)

Transformer

120VAC – White and Black

277VAC – White and Red

Note: Potential Shock Hazard –

Insulate Unused Lead

Fig.2

Fig.1