Hubbell Industrial Controls, Inc.

4220

INSTALLATION & MAINTENANCE INSTRUCTIONS

POWER LIMIT SWITCHES

EUCLID™ SIZE 2, 3, 4, 5, 6, & 6A

General

The EULCID™ Power Limit Switch is a device well

suited for crane hoist overtravel protection in repeti-

tively worked applications and under severe environ-

mental conditions. Maintenance requirements obvi-

ously will vary with service conditions. Even though

the device has been carefully designed to minimize

maintenance due to wear and adverse environmental

conditions, a periodic inspection and maintenance

program is mandatory in the interests of insuring

maximum protection.

The following sections treat various components of

the limit switch with suggested installation and main-

tenance practice.

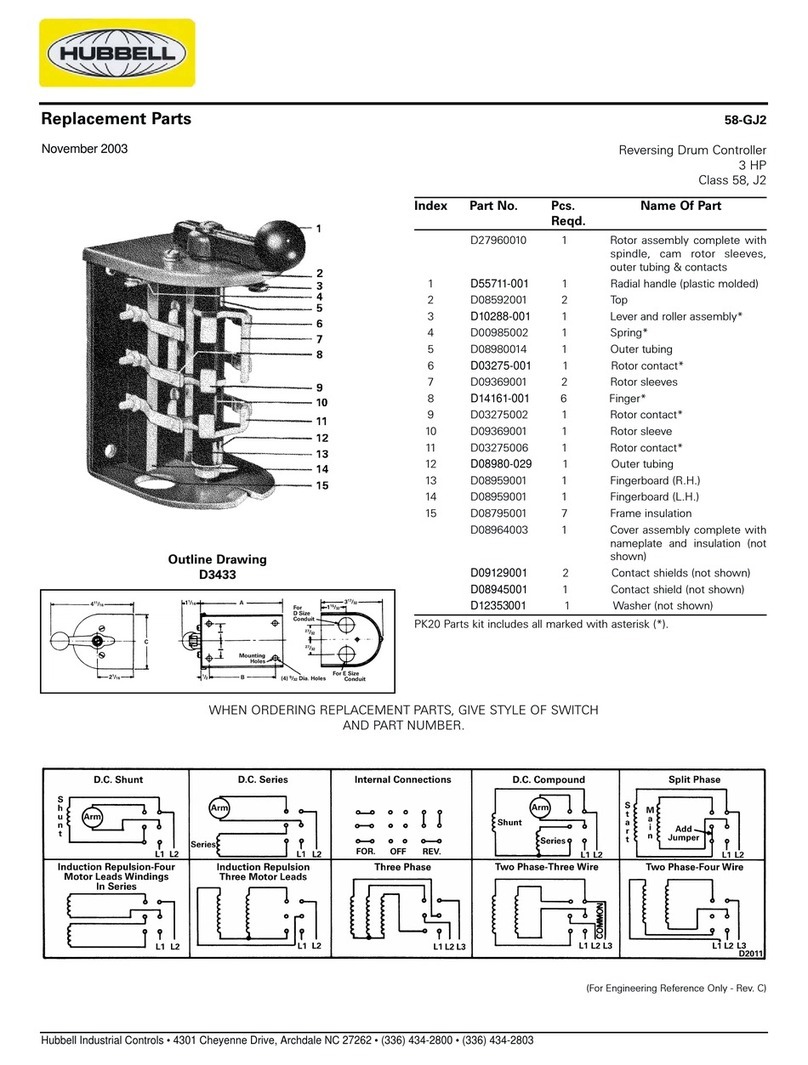

Installation

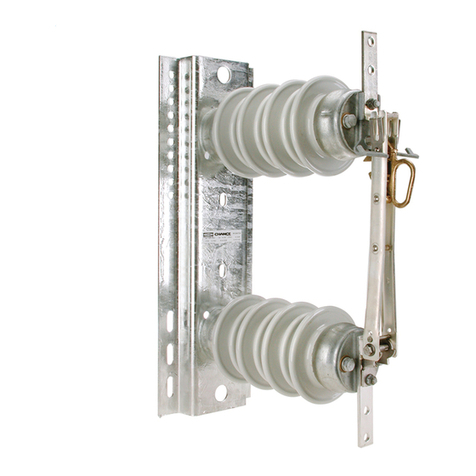

EUCLID™ Power Limit Switches must always be

mounted with shaft in horizontal position with mount-

ing feet down. Under no circumstances attempt to

mount up side down. Provide adequate support under

each of the three mounting feet.

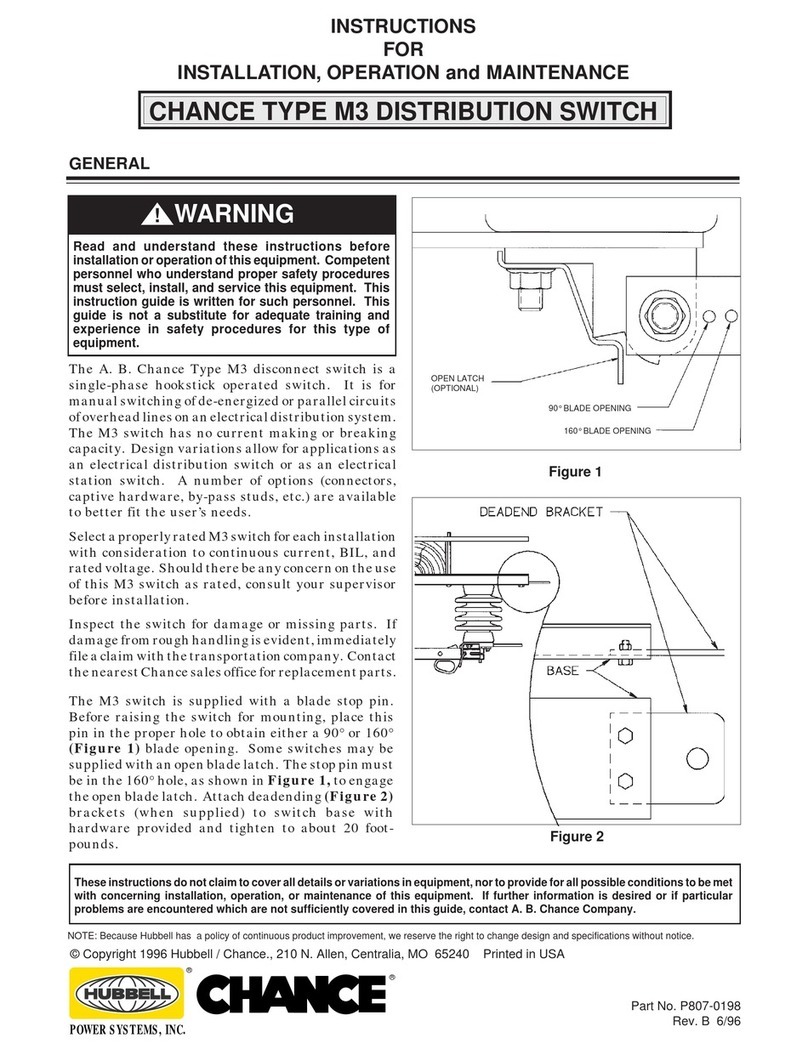

Install the split-sleeve reset weight guide around the

dead-ended cable, see Fig. 1. A bracket or striker

plate may be attached to the hook block, if necessary,

to lift the suspended weight when hoisting. Be sure

that the reset weight is positively engaged by the hook

block during hoisting under all conditions of hook

swing. Add additional guiding means to reset weight if

necessary to insure engagement by hook block.

Provide clearance or opening in Trolley platform so

that tripping weight cannot be prevented from drop-

ping slightly below level of mounting feet. This clear-

ance, or opening for the trip weight insures positive

switch action by preventing dirt buildup. Avoid the use

of sheave wheels or lever systems which can intro-

duce friction in reset weight cable assembly and re-

tard free action of tripping weight.

Right hand operation as shown, is furnished unless

otherwise specified. Field changing from right hand to

left hand operation is accomplished by turning trip arm

around and making proper electrical connections.

Terminal markings only are involved by this change.

Refer to wiring diagram for proper connections.

Maintenance

Periodic inspection for contact wear should be per-

formed. The size 3 and 6A contacts have a silver in-

lay. When the silver inlay is worn, both sets of con-

tacts should be renewed, see Fig. 5 for allowable

wear. Size 2, 4, 5 & 6 switches have solid copper

contacts as standard. Both sets of contacts should be

renewed when the contacts are worn, see Fig. 5 for

allowable wear. It is recommended that both the

movable and stationary contacts be renewed at the

same time.

Contact renewal steps are outlined in the following

procedure.