Pub. 42004-338J

G A I - T R O N I C S

®

A H U B B E L L C O M P A N Y

Rugged Analog Auto-Dial Telephones

TA B L E O F CO N T E N T S

GAI-TRONICS 3030 KUTZTOWN RD. READING, PA 19605 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

VISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Confidentiality Notice.....................................................................................................................1

General Information.......................................................................................................................1

Operation.........................................................................................................................................1

Installation ......................................................................................................................................2

Safety Guidelines.....................................................................................................................................2

Security Hardware..................................................................................................................................2

Conduit Installation Details (Applicable to Models 247-001 and 257-001)........................................2

Model 227-001.........................................................................................................................................4

Model 247-001.........................................................................................................................................6

Model 257-001.........................................................................................................................................8

Model 277-001.......................................................................................................................................10

Flush-Mount Installation.....................................................................................................................10

Surface-Mount Installation using a 236-00x Series or Model 238-001 Enclosure............................. 11

Models 277-001BH and 277-001BHAC...............................................................................................12

Flush-Mount Installation.....................................................................................................................12

Surface-Mount Installation using the No. 238-001FS Enclosure .......................................................13

Programming Auto-Dial Numbers......................................................................................................14

Ringdown Operation ............................................................................................................................14

Maintenance..................................................................................................................................15

Service....................................................................................................................................................15

Preventive Maintenance for Models 277-001/-001BH/-001BHAC...................................................15

Cleaning.............................................................................................................................................. 15

Prevention...........................................................................................................................................15

Volume Control Jumper Setting..........................................................................................................16

Auxiliary Output...................................................................................................................................16

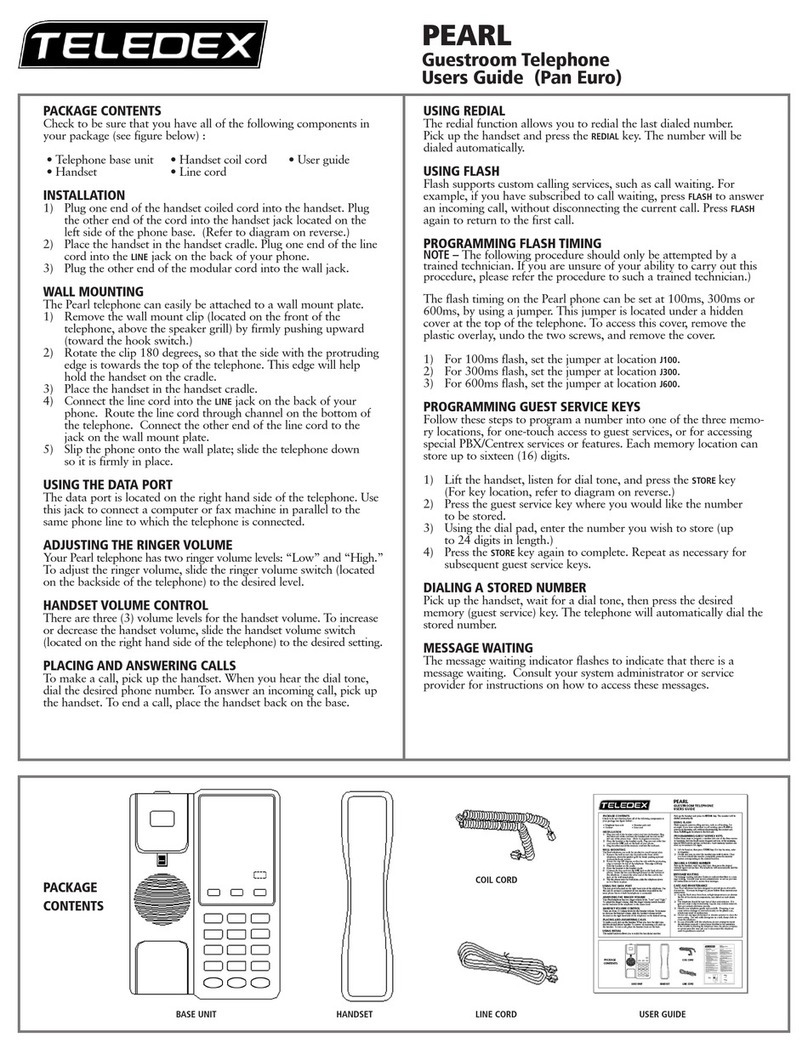

Replacement Parts and Accessories.............................................................................................17

Specifications ................................................................................................................................19

Electrical (Typical)................................................................................................................................19

Environmental.......................................................................................................................................19

Mechanical.............................................................................................................................................19

Model 227-001.......................................................................................................................................19

Models 247-001 and 257-001................................................................................................................19