Pub. 42004-455C

GAI-TRONICS

®

A HUBBELL COMPANY

Division 1 SMART Telephones

GAI-Tronics Corporation 3030 Kutztown Road, Reading, PA 19605 USA

610-777-1374 800-492-1212 Fax 610-796-5954

V

ISIT WWW

.

HUBBELL

.

COM

/

GAI

-

TRONICS

/

EN FOR PRODUCT LITERATURE AND MANUALS

Confidentiality Notice

This installation, operation, and maintenance manual contains sensitive business and technical

information that is confidential and proprietary to GAI-Tronics. GAI-Tronics retains all intellectual

property and other rights in or to the information contained herein. Use this information only in

connection with the operation of your GAI-Tronics product or system. Do not disclose this manual in any

form, in whole or in part, directly or indirectly, to any third party.

General Information

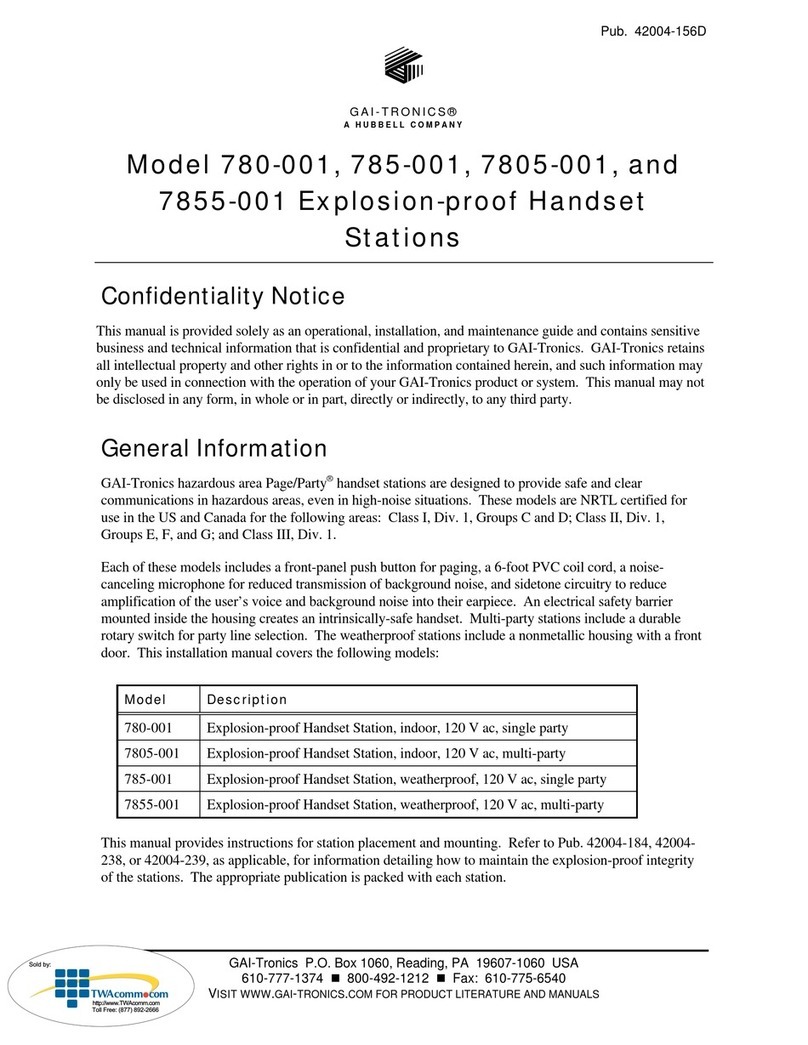

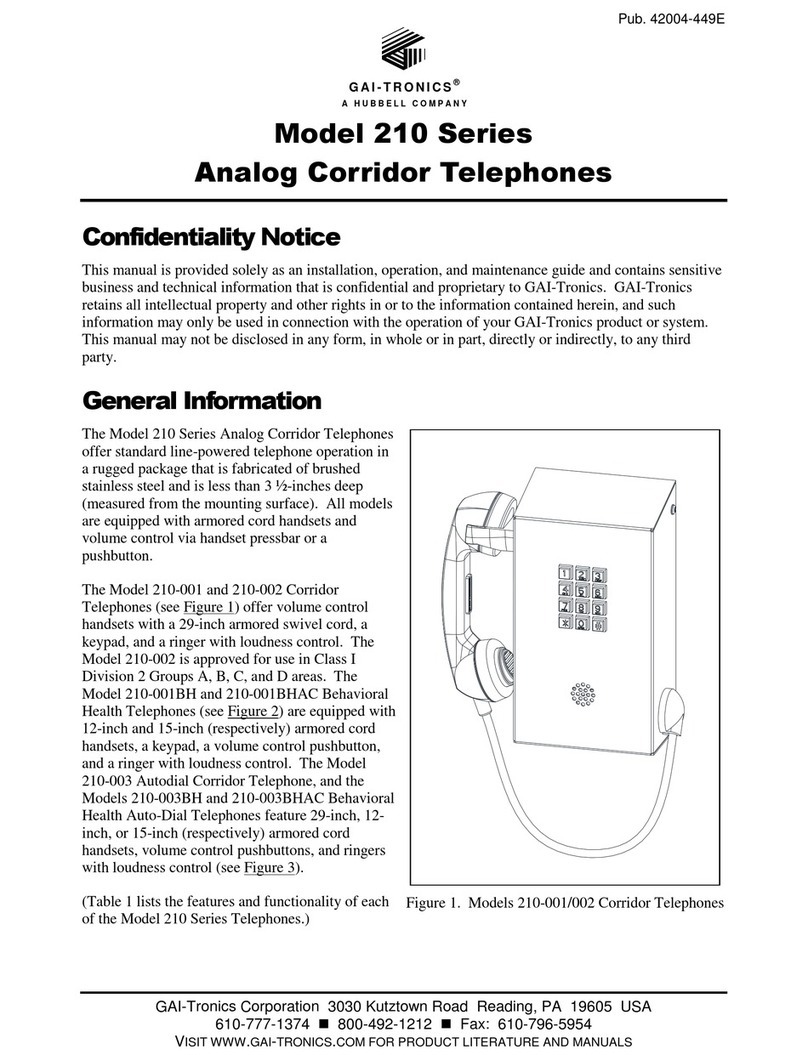

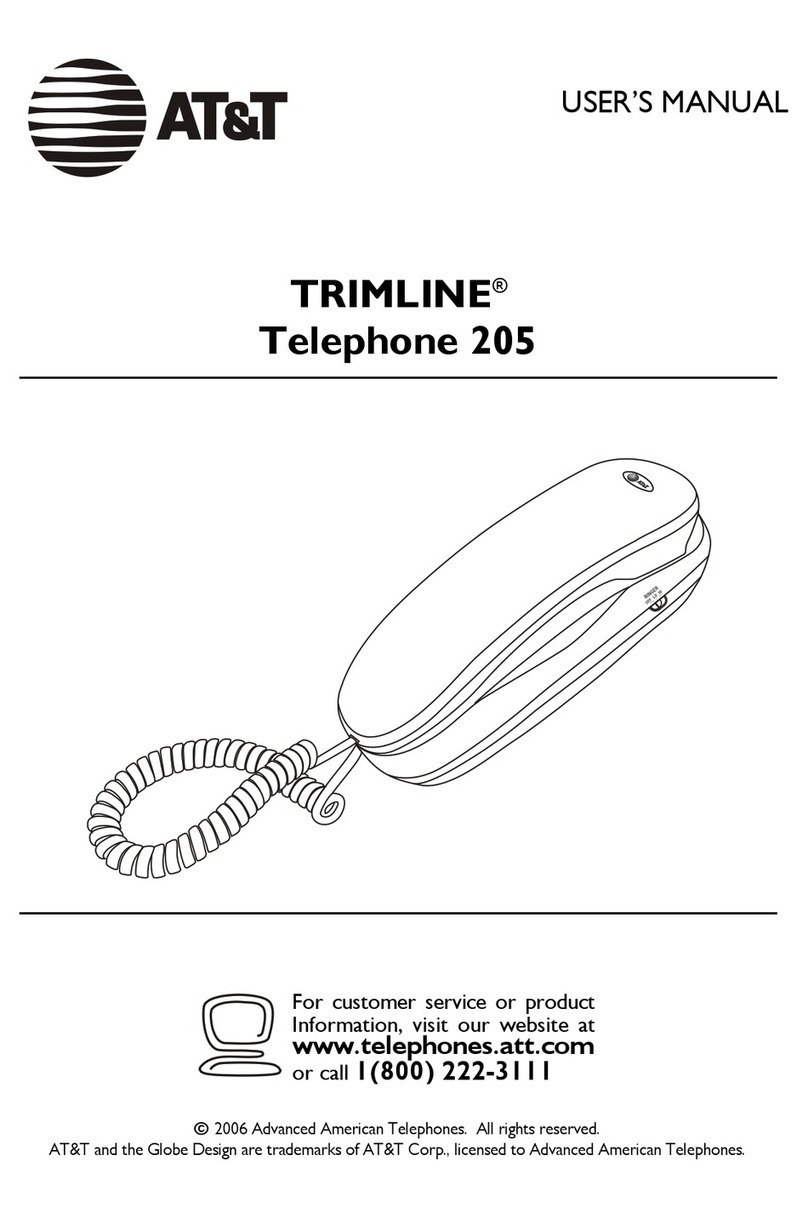

GAI-Tronics’ Class I, Division 1 SMART Hazardous

Area telephones are constructed of cast aluminum and

are weatherproof and corrosion resistant. They combine

standard telephone operation with GAI-Tronics’

SMART (self-monitoring and reporting telephone)

technology to provide optimum performance and

flexibility.

Using GAI-Tronics’ TMA (Telephone Management

application) (purchased separately) provides status

monitoring and reporting for each telephone. For

complete details, please refer to the TMA’s on-line

help.

This manual applies to the following models:

•Model 352-101—Division 1 SMART Hazardous

Area Telephone

•Model 352-102—Division 1 SMART Hazardous

Area Telephone with Ring Relay

•Model 352-103—Division 1 SMART Hazardous

Area Telephone with Headset

•Model 352-104—Division 1 SMART Hazardous Area Telephone with Ring Relay and Headset

GAI-Tronics’ SMART telephone product line provides flexibility to address a diverse range of

applications. Altering the configuration data, in the telephone’s non-volatile memory, achieves a wide

variety of functions. The configuration options include:

•call progress detection, control, and call logging,

•auto-calling, auto-answering, and auto-dialing facilities,

•function inhibiting (e.g., tone pad and manual keypad dialing), and

•maximum call duration.

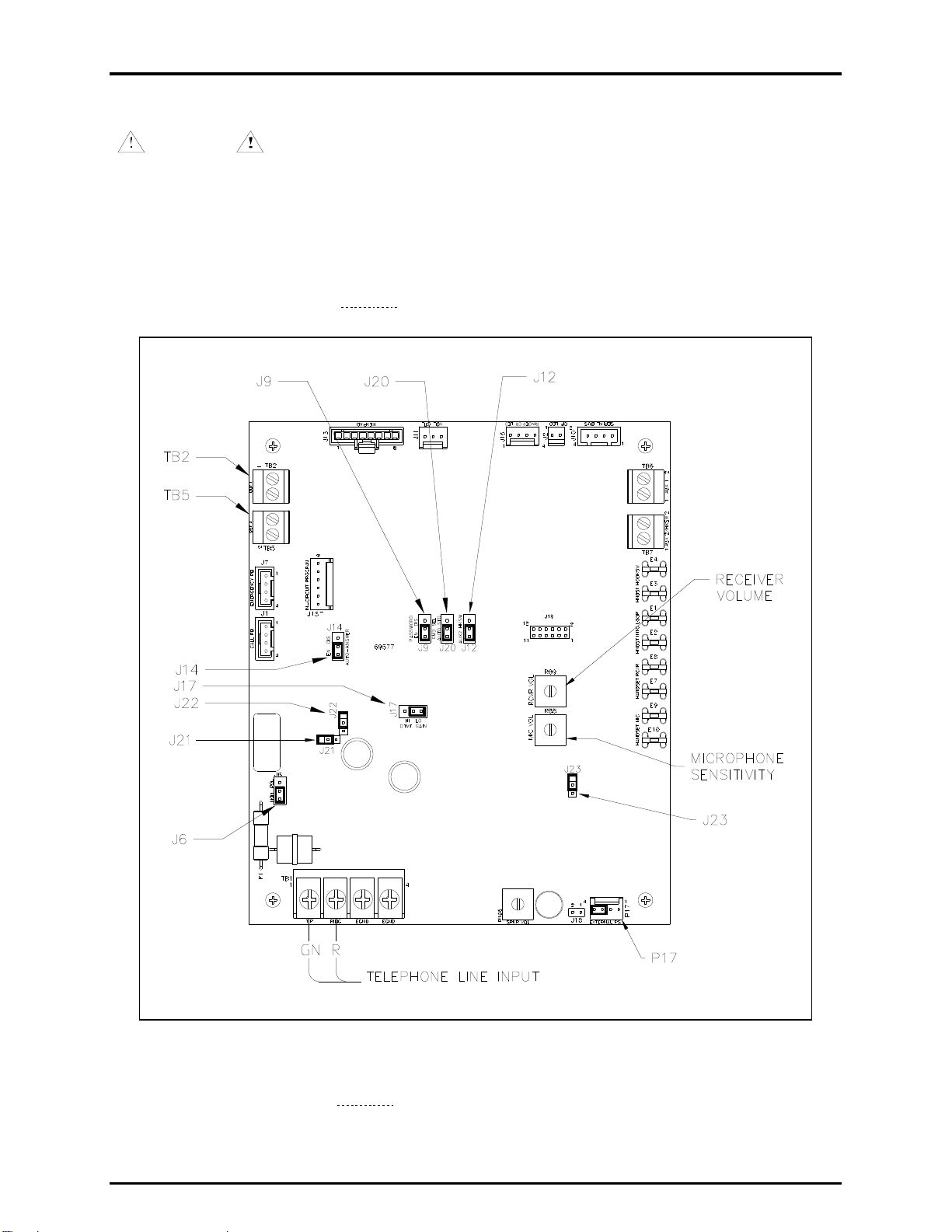

Figure 1. Model 352-101 Division 1

SMART Hazardous Area Telephone