MODEL 913H POWERIG® HYDRAULIC UNIT Alcoa Fastening Systems

8

MAINTENANCE (CONT.)

PREVENTIVE MAINTENANCE

An effective preventive maintenance program

includes scheduled inspections to detect and

correct minor troubles.

1. Verify that hydraulic hose fittings and

electrical connections are secure.

2. Inspect hoses for signs of damage.

REPLACE HOSES IF DAMAGE IS

DETECTED. Use of a defective hose may

result in Severe personal injury and

damage to the tool .

3. Inspect components during operation to

detect any abnormal heating, leakage,

vibration, or wear.

4. Inspect oil filter periodically. If necessary,

clean according to instruction tag.

5. Inspect hydraulic fluid periodically. Replace

if any evidence of impurities is detected.

6. Keep all exterior surfaces clean.

Perform the following maintenance on the

engine:

1. Check oil every five operating hours, and

each time before using Hydraulic Unit.

2. Change crankcase oil after first two hours of

operation. Thereafter, change crankcase oil

every 25 hours of operation. If power

source is operated in extremely dusty or

dirty environment, change oil every eight

hours of operation.

Unscrew oil drain plug (Figure 3 - Item 18),

tip engine toward oil drain hole and drain

completely. Replace oil drain plug and refill.

3. The air-cooled engine operates most

efficiently when cooling fins are kept clean.

Remove all dust and dirt from cylinder fins

and underside of housing, as required.

4. A dirty or clogged air cleaner results in

noticeable loss of engine power. Clean the

reusable-type air cleaner each 10 operating

hours, or more frequently if unit is operating

in dusty or dirty environment. To clean,

remove air cleaner (Figure 3 - Item 19) and

dip in gasoline.

5. Remove and inspect spark plug (Figure 2 -

Item 16) at each oil change. Keep

electrodes clean and free of carbon. Adjust

electrode gap to .030 inch. If electrodes are

pitted or burned or ceramic insulator is

cracked, replace spark plug. Before

installing a spark plug, coat threads lightly

with graphite grease.

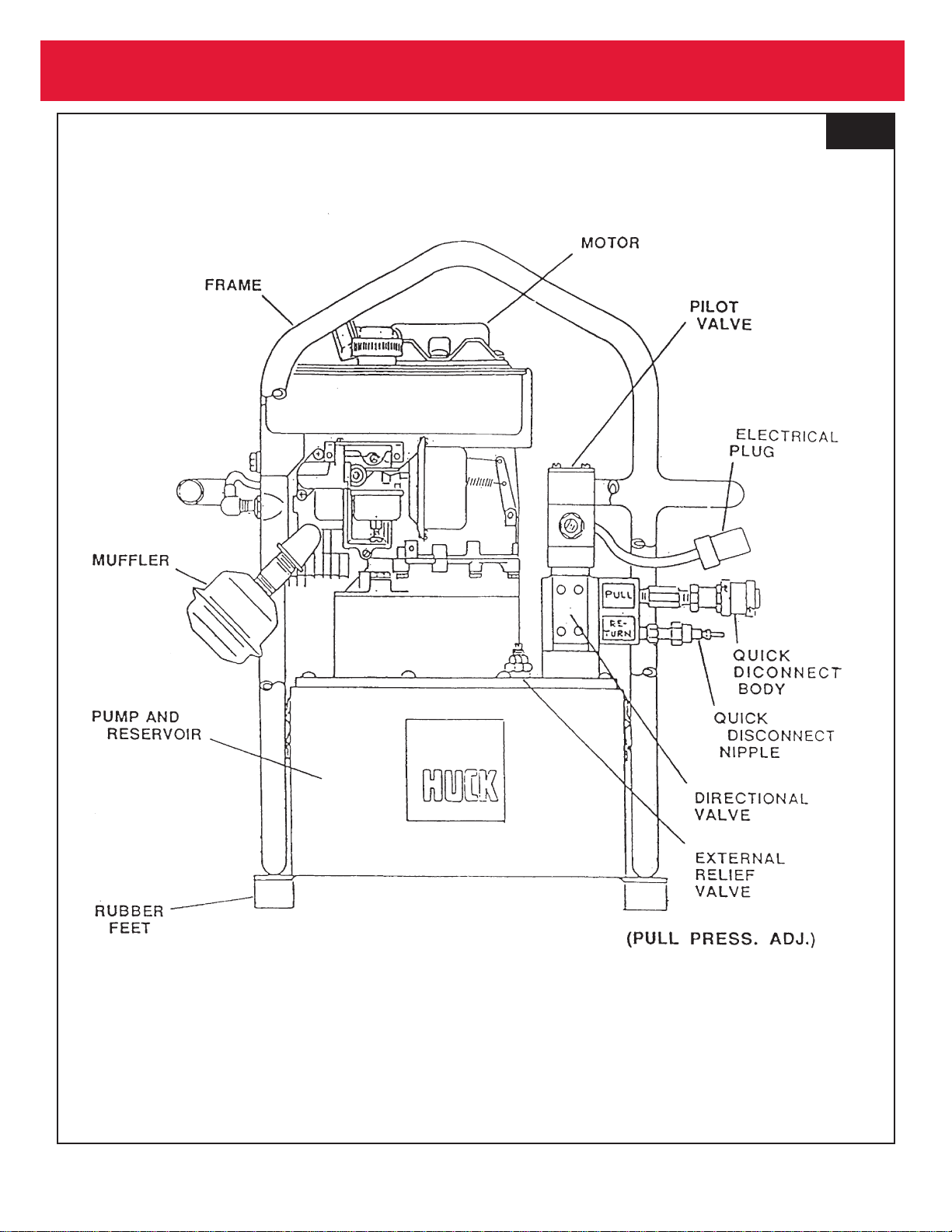

PRESSURE ADJUSTMENTS

NOTE: Do not adjust PULL or RETURN

pressure unless a T-10280 (earlier

model) or T-124833 Pressure Gauge is

on hand. Follow instructions supplied

with pressure gauge for proper pressure

checking and adjusting.

PULL pressure adjustment:

Refer to Figure 1.

1. Loosen jam nut on relief valve

2. Turn adjustment clockwise to increase

PULL pressure -- counter-clockwise

decreases pressure.

3. Tighten jam nut.

RETURN pressure adjustment:

Refer to Figure 3.

Same procedure as PULL adjustment.

NOTE: Relief valve jam nut must always

be tightened all the way clockwise once

pressure is set. Tightening will assure

settings won't "drift" while the hydraulic

unit is operating.