5

10

15

20

25

30

35

40

45

"t--

s -..... <

...

Parts

Li

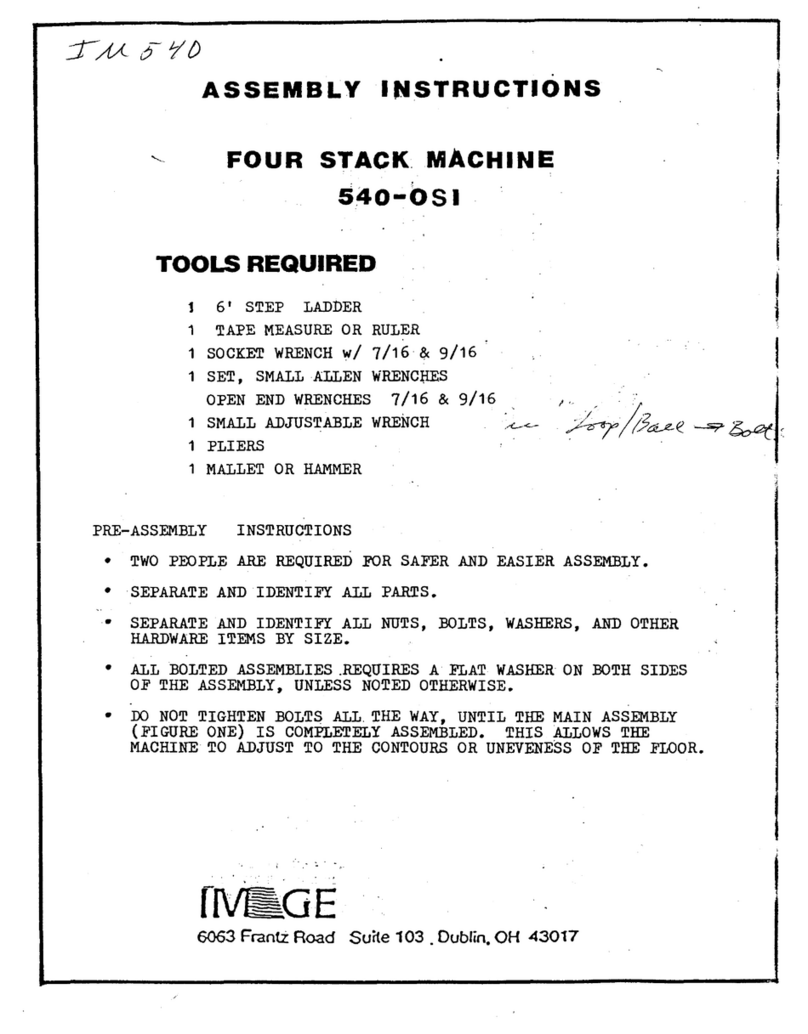

NOTE: SOME OF THESE PARTS MAY COME PRE-INSTALLED

i

I

Item No. Description Qty Item No. Description Qty

1 Weight Stack Frame 1

50

Plastic Tube Guide 2

2 Seat Pad Frame 1

51

Hand Cushion 1

3 Curl Arm Adjustment,Assy 1 52 Grip

<1>30*<1>22*270

2

4 Extension

Arm

Adjustment,Assy 1 53 Plug RT 40*80 3

Cable

Cam

1

54

Separate Cap

<1>17*10.5

3

6 Guide Rod 2 55 Socket Head Cap Screw M8*20 3

7 Front Frame 1 56 Hex Head Bolt M10*115 4

8 Bottom Cross Brace 1 57 Hex Head Bolt M10*110 6

9 Rear Brace 1 58 Hex Head Bolt M10*105 4

Adjustable Plate 1 59 Hex Head Bolt M10*25 4

11

Adjustable Plate 1 60 Hex Head Bolt M10*20 2

12 Ext/Curl Arm 1

61

Hex Head Bolt M10*45 1

13 Ankle Roller Frame 1 62

Hex

Head Bolt M10*50 8

14 Side Frame 1 63 Hex Head Bolt M10*65 8

Handle 1 64 Button Head Cap Screw M10*25 2

16 Back Pad 1 65 Flat Head Cap Screw M10*25 2

17 Big Washer<1>63.5*4 2 66 Pan Head Phillips Screw M8*55 1

18 Seat Pad 1 67 Hex Head Bolt M8*40 2

19 Weight Stack Base 2 68 Socket Head

Cap

Screw M8*25 1

Adjustable Support 1 69 Flat Head Cap Screw M5*10 1

21

Adjustment Bush 1 70 Pan Head Phillips Screw M5*15 8

22 Back Pad Frame 1

71

Nylon lock Nut M10 27

23 Lid

Plate<1>38*<1>10.5*4

4

72

Nylon lock Nut M8 5 •

24 Pin

For

Extension/ Curl 1 73

Washer

<1>11

*<1>20*1.5

70

Pin For Thigh Pad

Assy

1 74 Washer

<1>18*<1>9*1.5

8

26 Pop Pin 1 75 M12*40 Hex Head Bolt

2:

27 Thigh Pad Frame

Assy

1 76 FOAM 2

28 Pin Link Plate 4 77 Bush

of

Rolling Pad 4

29

Long Adjustment Bush 1 78 Hex Head Bolt M12*80 2

Pulley Prevent Bracket 1 79 Socket Head Cap Screw M5*20 4

31

Top Plate 1 80

Washer

<1>5.5*<1>10*1

8

32 Spring 1

81

Nylon lock Nut

M5

4

33 Selector Pin W/Coil 1 82 Nylon lock

Nut

M12 4

34 Pillow Block BearlngUCFL205-25 2 83 Washer

<1>13*<1>24*2

8

Plug RT50*100 1 84 Socket Set Screw 10-32*3.2 8

36 Bottom Front Shroud 1 85 Plug RT 30*70 3

37 Bottom Rear Shroud 1 86

<1>25.4

Ring 2

38 Top Front Shroud 1 87

<1>25.4

End

Cap

2

39 Top Rear Shroud 1 88 Oval Fixed Plate 3

Guide Rubber

Bumper<1>25*<1>21

*28 4 89 Bushing

<1>10*<1>14*20

1

41

Yellow

Grip<1>19*<1>

14*70 2

90

Spacer

<1>16*<1>12.2*12.5

4

42

M10*55 Hex Head Bolt 2

91

U-Style Tapped Hole Nut M5 4

43

4.5" Pulley 5

92

Hex Head Bolt M10*135 1

44

3.5" Pulley 1 93 Hex Head Bolt M10*190 1

Cable 1 94 Hex Head Bolt M10*50(Whole Screw) 2

46

Bushing

<1>38*<1>25.4*18

6

95

Hex Key S=6 1

47

Bushing<1>16*

<1>

12*8 4 96 Hex Key

S=4

1

48 Weight Rubber Bumper 2 97 Lube 1

49

Foot Pad

5·

! There are two configuration of weights: 250LBS(sixteen 15LBS Weight Plate)

and 170LBS(sixteen 10LBS Weight Plate), please see following form for details.

-5-