SAFETY INSTR

UCTIONS

English

–

7

Mac

hine

′

s safety equipment

This section descr

ibes the machine

′

s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

Emer

gency stop

The emergency stop at the machine breaks the mains

power supply.

T

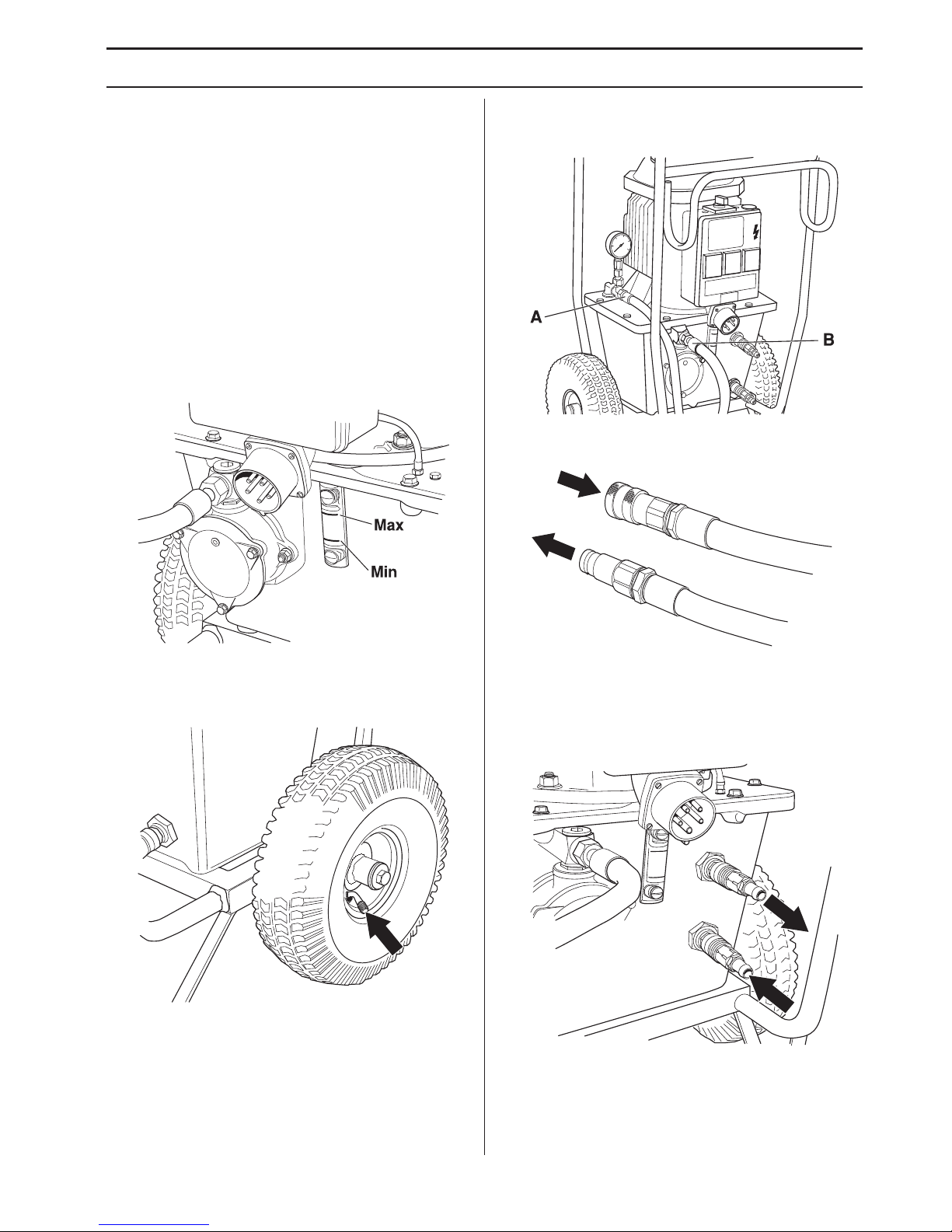

esting the emergency stop

•

Make sure that the hydraulic hoses are connected to

each other.

• Start the machine.

• Press the emergency stop and check that the engine

stops.

General saf

ety precautions

Do not use the machine without fi

rst reading and

understanding the contents of this Operator’s Manual.

• Never use the machine if you are tired, if you have

drunk alcohol, or if you are taking medication that

could affect your vision, your judgement or your co-

ordination.

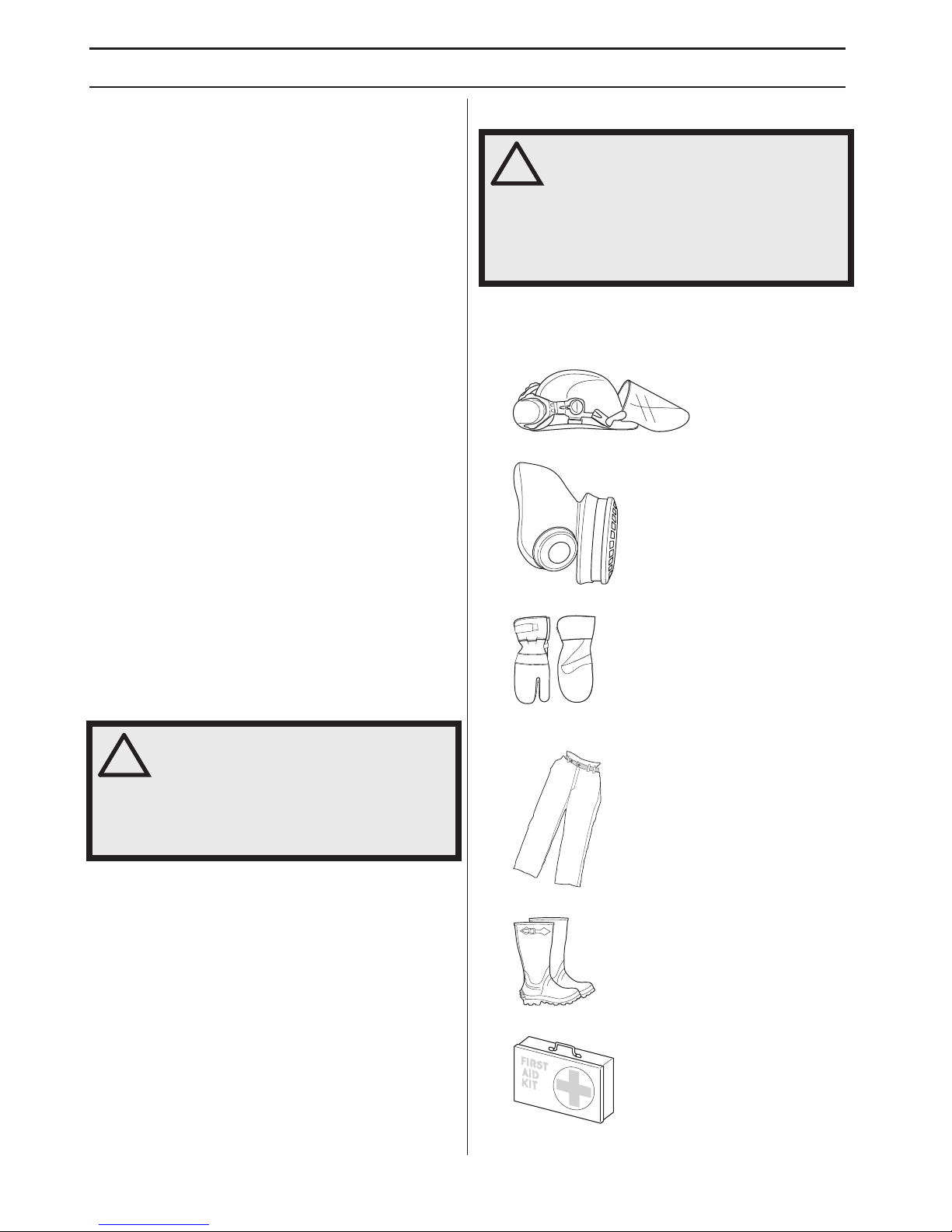

• Wear personal protective equipment.See instructions

under the heading ”Personal protective equipment”.

• Never pull out the plug by pulling the cord.

• Regularly check that the battery charger connection

wire is intact and that there are no cracks in it. Keep

all cables and extension leads away from water, oil

and sharp edges. Make sure the cable is not jammed

in doors, fences or the like.Otherwise it can cause the

charger to become live.

• Check that the cord and extension cord are intact and

in good condition.

• Never use the machine if the cord is damaged, hand

it in to an authorized service workshop for repair.

• To avoid overheating do not use the extension cord

while it is rolled up.

• The machine should be connected to an earthed

outlet socket.

• Check that the mains voltage corresponds with that

stated on the rating plate on the machine.

• Always switch off the power to the hydraulic unit and

pull out the electric cable before moving the

equipment.

• Keep all parts in good working order and ensure that

all fixtures are properly tightened.

• Never use a machine that is faulty. Carry out the safety

checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained and

qualified specialists. See instructions under the

heading Maintenance.

• Do not modify safety equipment. Check regularly that

they function as they should. The machine must not

be run with defective or disassembled safety

equipment.

• Never allow anyone else to use the machine without

first ensuring that they have read and understood the

contents of the operator’s manual.

• People and animals can distract you causing you to

lose control of the machine. For this reason, always

remain concentrated and focused on the task.

• Make sure no unauthorised persons are in the

working area, otherwise there is a risk of serious

personal injury.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• Observe care when lifting.You are handling heavy

parts, which imply the risk of pinch injuries or other

injuries.

T

ransport and storage

•

Always switch off the power to the hydraulic unit and

pull out the electric cable before moving the

equipment.

• If there is a risk of freezing, the machine must be

drained of any remaining water coolant.

• The power pack is constructed as a wheeled cart with

the possibility of hanging hydraulic hoses for simple

transportation at the workplace.

• For transportation between workplaces, the power

pack should be stored in vertical position with the

distribution box facing upwards.

• Store the equipment in a lockable area so that it is out

of reach of children and unauthorized persons.

!

W

ARNING! Never use a machine that has

faulty safety equipment!

All servicing and repair work on the

machine requires special training.This is

especially true of the machine

′

s safety

equipment. If your machine fails any of

the checks described below you must

contact your service agent.When you

buy any of our products we guarantee

the availability of professional repairs

and service. If the retailer who sells your

machine is not a servicing dealer, ask

him for the address of your nearest

service agent.

!

W

ARNING! There is always a risk of

shocks from electrically powered

machines. Avoid unfavourable weather

conditions and body contact with

lightning conductors and metal objects.

Always follow the instructions in the

Operator’s manual to avoid damage.