English – 9

OPERATING

Always use common sense

It is not possible to cover every conceivable situation you can

face. Always exercise care and use your common sense. If

you get into a situation where you feel unsafe, stop and

seek expert advice. Contact Discount-equipment. Do not

attempt any task that you feel unsure of!

Work safety

Work area safety

•Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• The safety distance is 4 meters (15 ft) from the machine.

• Always check and mark out where gas pipes are routed.

Cutting close to gas pipes always entails danger. Make

sure that sparks are not caused when cutting in view of the

risk of explosion. Remain concentrated and focused on

the task. Carelessness can result in serious personal

injury or death.

• Do not use the machine in environments where there is a

risk of explosion.

• Make sure that no pipes or electrical wires are routed in

the work piece or in the working area.

• Make sure that electrical cables within the working area

are not live.

• Observe your surroundings to ensure that nothing can

affect your control of the machine.

• Do not use the machine in bad weather, such as dense

fog, heavy rain, strong wind, intense cold, etc. Working in

bad weather is tiring and can lead to dangerous

conditions, e.g. slippery surfaces.

• Do not use the machine in wet or humid surroundings,

close to water, in the rain or snow.

• Never start to work with the machine before the working

area is clear and you have a firm foothold.

Electrical safety

• Always connect the machine through an ground fault

circuit interrupter with personal protection, i.e. an ground

fault circuit interrupter that trips at an ground fault of 30

mA.

• The machine should be connected to an earthed outlet

socket.

• Check that the mains voltage corresponds with that stated

on the rating plate on the machine.

• Check that the cord and extension cord are intact and in

good condition. Always use extension cables that are

approved for outdoor use.

• Never use the machine if any cable or plug is damaged,

but hand it in to an authorized service workshop for repair.

• To avoid overheating do not use the extension cord while

it is rolled up.

•Never drag the machine by means of the cord and never

pull out the plug by pulling the cord.

•Keep all cables and extension leads away from water, oil

and sharp edges. Make sure the cable is not jammed in

doors, fences or the like. Otherwise it can cause the

charger to become live.

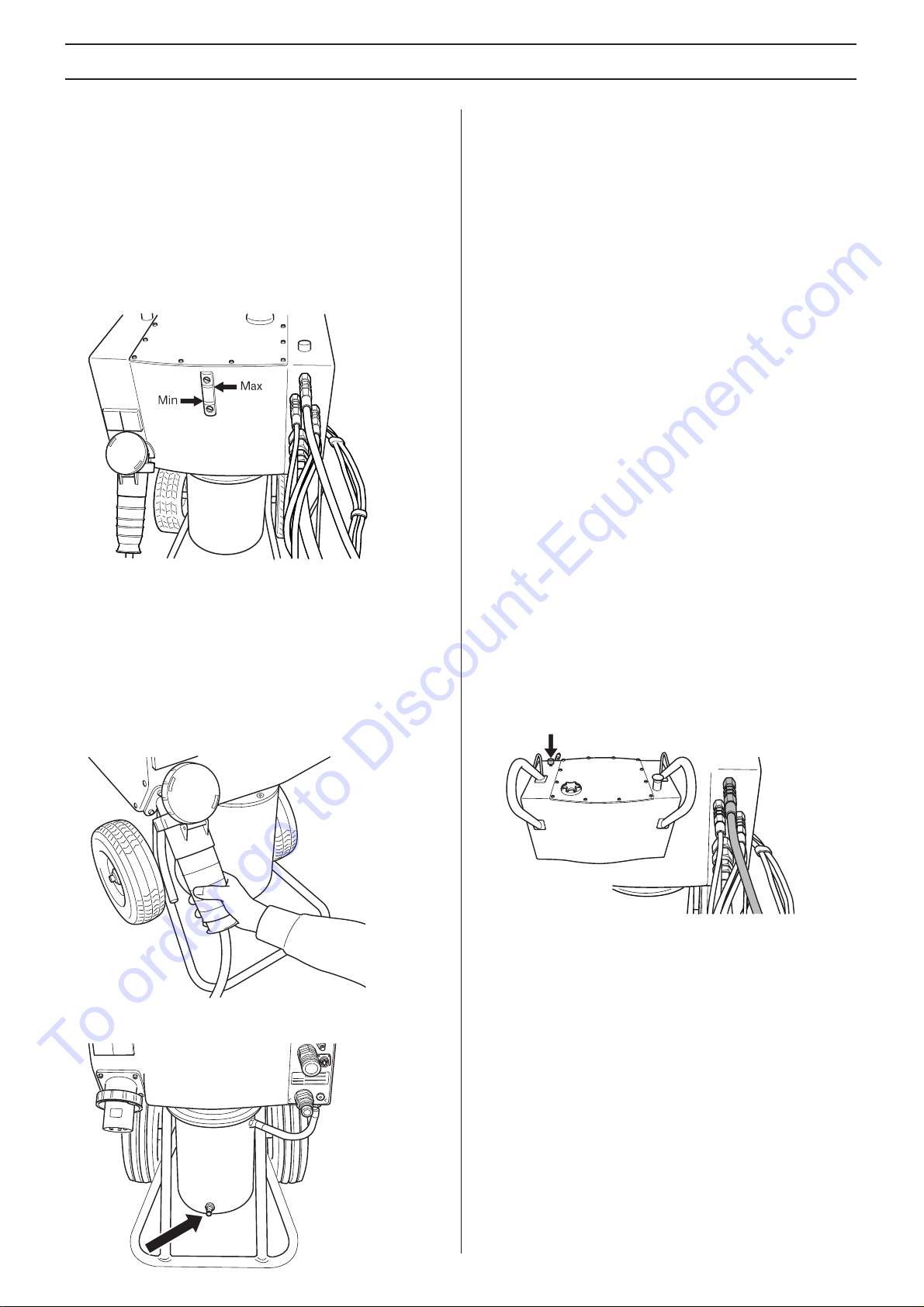

Hydraulic safety

•Check that all couplings, connections and hydraulic hoses

are in full working order.

• Keep the hydraulic hoses and couplings free from dirt.

• Do not misuse hoses.

• Do not use hoses that are distorted, worn or damaged.

• Check that the hoses are connected correctly to the

machine and that the hydraulic couplings lock as intended

before pressurising the hydraulic system. The couplings

are locked by turning the outer sleeve on the female

coupling so that the slot moves away from the ball.

The pressure hoses in the system must always be

connected to the tool’s intake. The return hoses in the

system must always go to the tool’s outlet. Confusing the

connections can cause the tool to work in reverse, which

can result in personal injury.

• Never use the hydraulic hoses to lift the machine.

• Check the machine, couplings and hydraulic hoses daily

for leakage. A rupture or leak can cause a ”hydraulic oil

injection” in the body or result in other serious physical

injury.

• Never disconnect the hydraulic hoses without first shutting

off and disconnecting the hydraulic unit and ensuring the

motors have stopped completely. If despite all precautions

an emergency situation should arise, press the red

emergency stop button on the top of the unit or press the

green start/stop button on the remote control.

• Do not exceed the specified hydraulic oil flow or pressure

for the tool being used. Excessive pressure or flow can

result in rupturing.

• Do not check for leakage with your hands. Contact with

the leak can result in serious personal injury caused by

the high pressure in the hydraulic system.

• Hoses that are marked and approved as electrically non

conductive must be used when using hydraulic tools on or

in the vicinity of electrical cables.The use of other types of

hoses can result in serious physical injury or even death.

• When replacing hoses, hoses marked 'non-conducting

dielectric” must be used. The hoses must be regularly

checked for their electrical conductive insulation in

accordance with special instructions.

• Run the hydraulic system until it reaches its operation

temperature of 30°C before starting to saw, to reduce

return pressure and other wear.

!

WARNING! There is always a risk of shocks

from electrically powered machines. Avoid

unfavourable weather conditions and body

contact with lightning conductors and metal

objects. Always follow the instructions in the

Operator’s manual to avoid damage.

!

WARNING! Do not wash the machine with

water, as water can enter the electrical

system or the engine and cause damage to

the machine or short circuit.

To order go to Discount-Equipment.com