ENGLISH

1.3.4 During operation

•If any persons or vehicles approach the danger area (10 m radius), stop the attachment

immediately.

•Never leave the operator console while moving.

•Only leave the operator console when the tools on the attachment have come to a standstill.

•Do not make any adjustments to the attachment during operation as this results in a risk of

accidents.

•Carrying persons or objects is prohibited.

•If the attachment has picked up a foreign body, for example, and is blocked, turn off the

auxiliary power unit, stop the motor and remove the ignition key. The attachment can then be

cleared of foreign bodies with a suitable tool. Work must be carried out carefully and

observantly, as the components may be braced against one another and could slip abruptly.

•In case of damage, stop the attachment and have the damage repaired.

•If the attachment is vibrating excessively, stop the machine immediately and have the fault

repaired by a specialist engineer. Do not continue working under any circumstances.

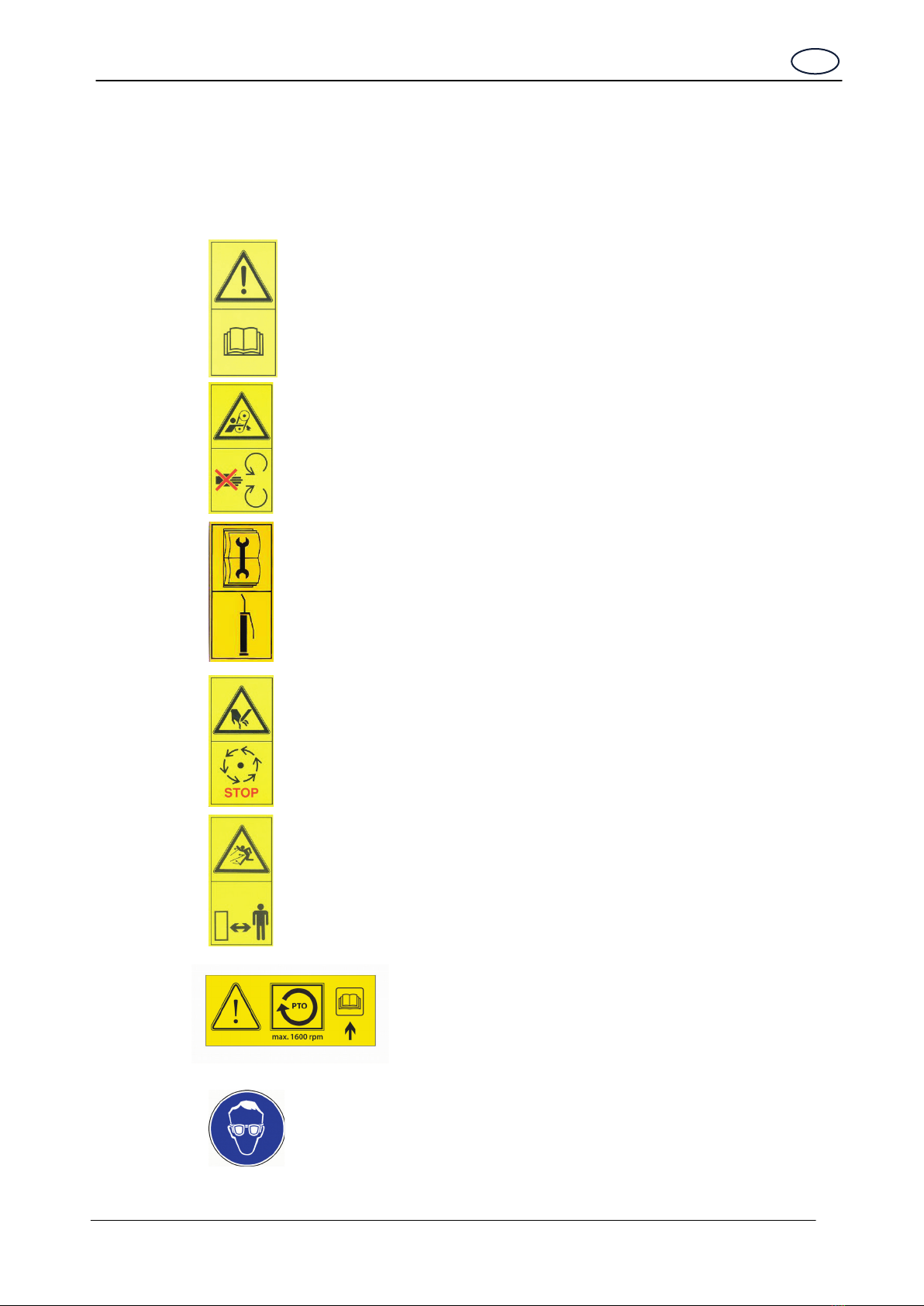

1.3.5 Maintenance, cleaning and repair work

•Only the work described in this operating manual may be carried out to care for and maintain

the weed brush.

•Perform maintenance and cleaning work only with the drive turned off and when the motor is

stopped.

•If protective equipment and working tools are subject to wear, they must be checked regularly

and replaced if necessary.

•Damaged brush sections must be replaced.

•When replacing brush sections, use appropriate tools and wear protective gloves.

•Only use genuine spare parts from the manufacturer, as they comply with the technical

requirements and thus minimize the risk of accidents.

•Carry out cleaning work with a high-pressure cleaner, ensuring that the water jet is not aimed

directly at bearings, rotating parts, lubricating nipples, shaft sealing rings, wheel hubs, etc.

After every clean with the high-pressure cleaner, the lubricating points must be regreased.

Failure to comply with this requirement voids all warranty entitlements.

•Check the moving parts for free movement and regrease as required.

•After maintenance and cleaning work, always re-install the safety equipment and set it to

safety position.

•Keep the machine clean to reduce the risk of fire.

•Regularly check that nuts and bolts are tightly fitted and tighten if necessary.

•For maintenance, cleaning and repair work on a raised unit, always use appropriate supports

to ensure safety.

•Before repair work, make sure that the hydraulic system is depressurized as pressurized fluid

can penetrate the skin and cause serious injuries. If injuries of this kind occur, seek medical

attention immediately as there is a risk of infection.

•Repairs may only be carried out by specialist personnel.

•Inspect hydraulic hoses for damage and aging at regular intervals and replace if necessary.

Replace all hoses after a maximum of 6 years of operation. The date of manufacture is

embossed on the hose.

9