Hussmann IMPACT ED1 User manual

Other Hussmann Merchandiser manuals

Hussmann

Hussmann GSVM User manual

Hussmann

Hussmann NRCV User manual

Hussmann

Hussmann D5XEE Instruction Manual

Hussmann

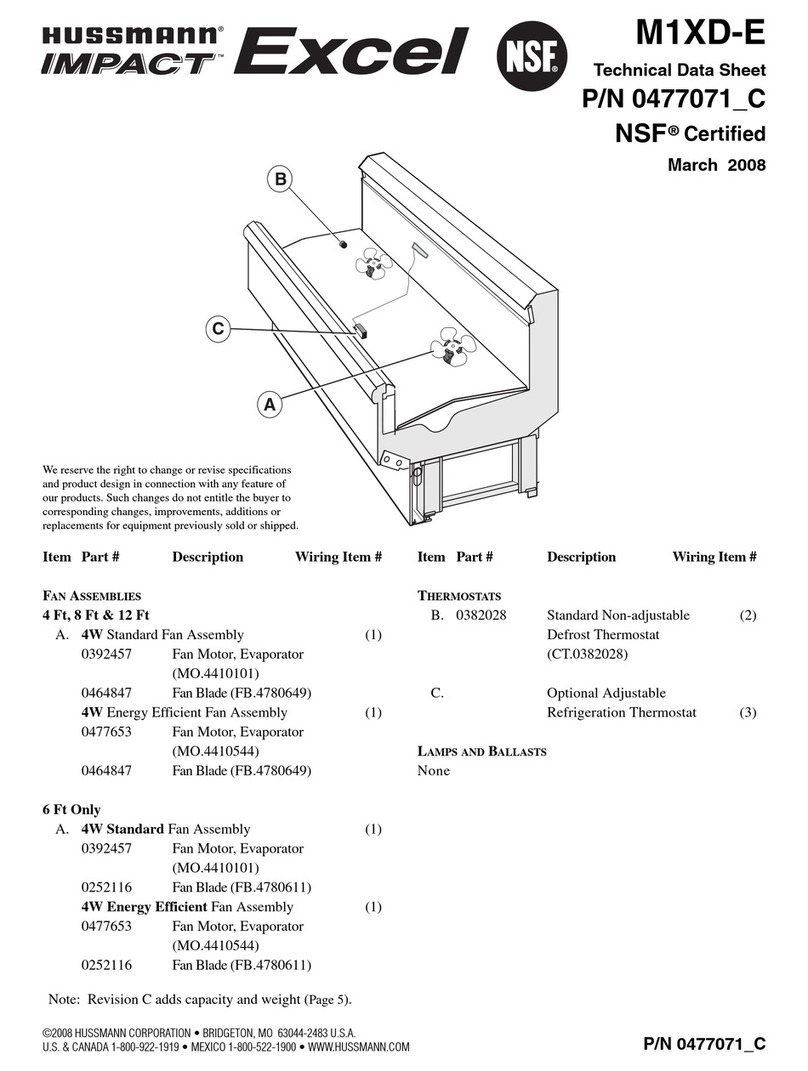

Hussmann M1XD-E Instruction Manual

Hussmann

Hussmann DSIO3-Y Operating instructions

Hussmann

Hussmann Q1-SS Instruction Manual

Hussmann

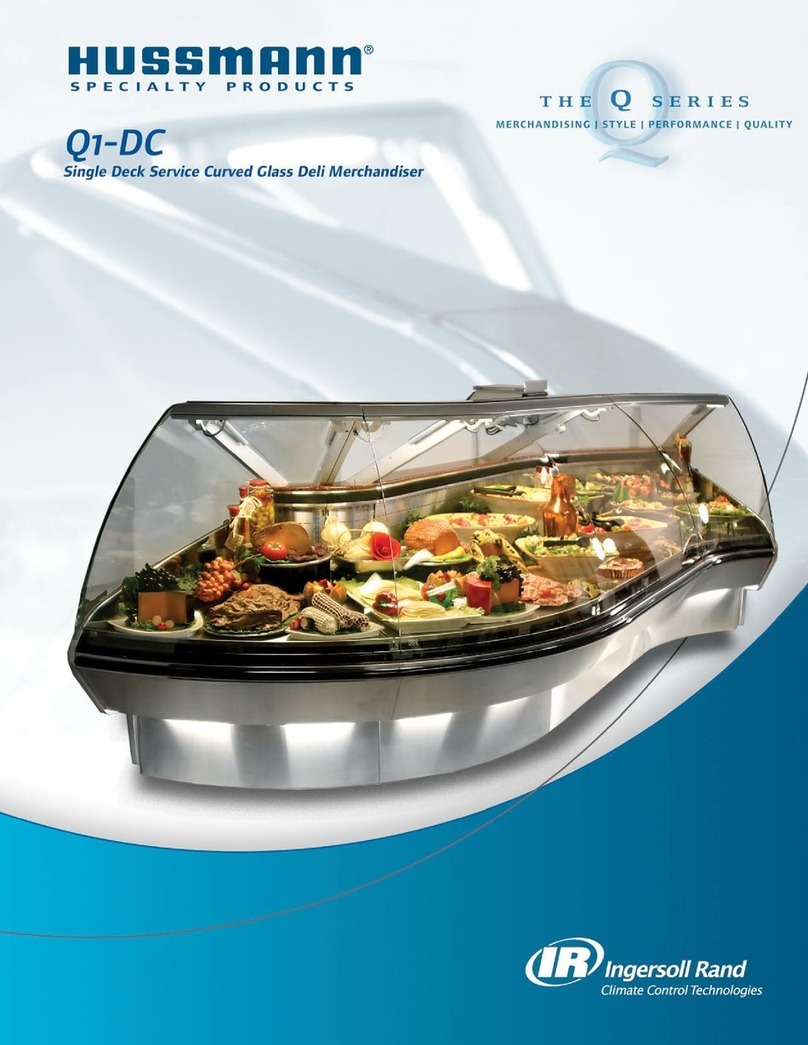

Hussmann Q1-DC Wedge User manual

Hussmann

Hussmann FG Manual

Hussmann

Hussmann SHVSS-C Operating instructions

Hussmann

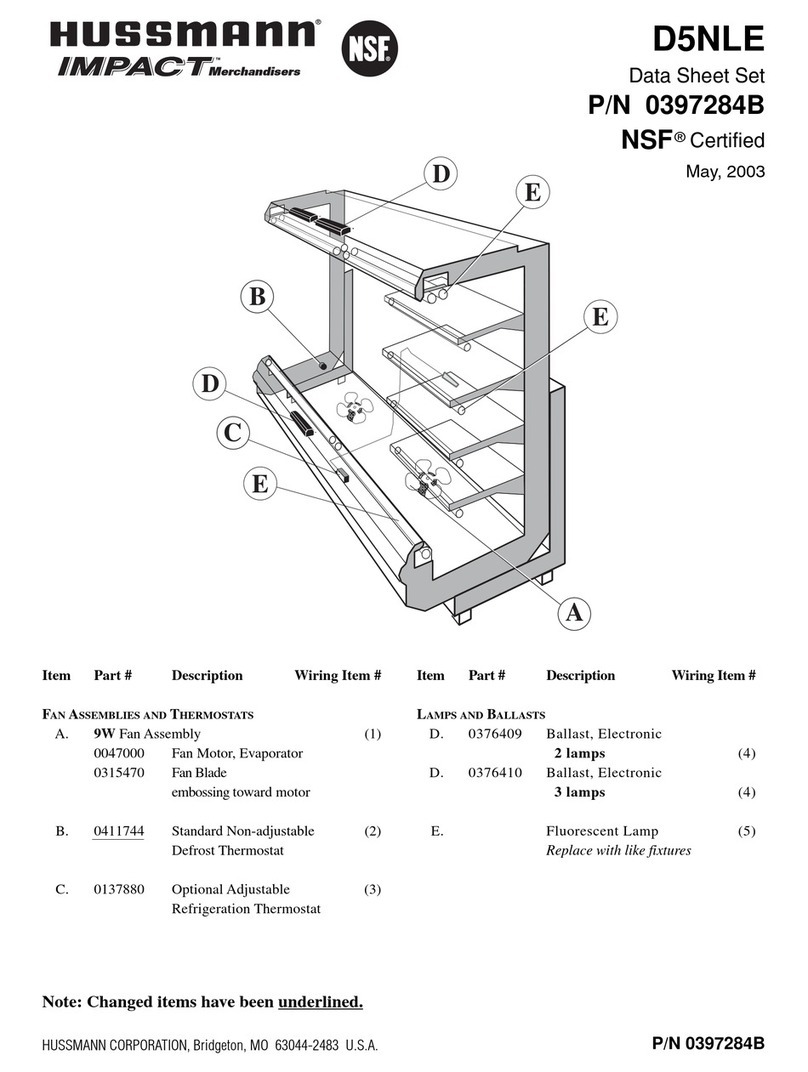

Hussmann IMPACT D5NLE User manual

Hussmann

Hussmann Impact C2-E User manual

Hussmann

Hussmann FW User manual

Hussmann

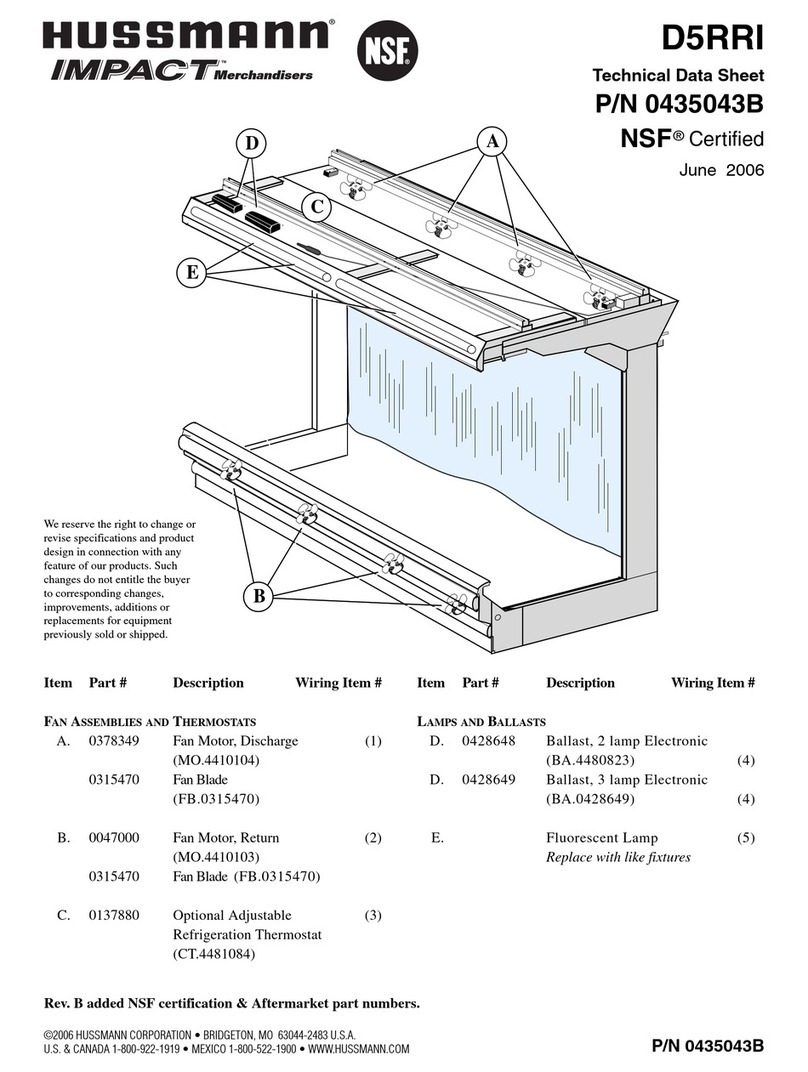

Hussmann IMPACT D5RRI Instruction Manual

Hussmann

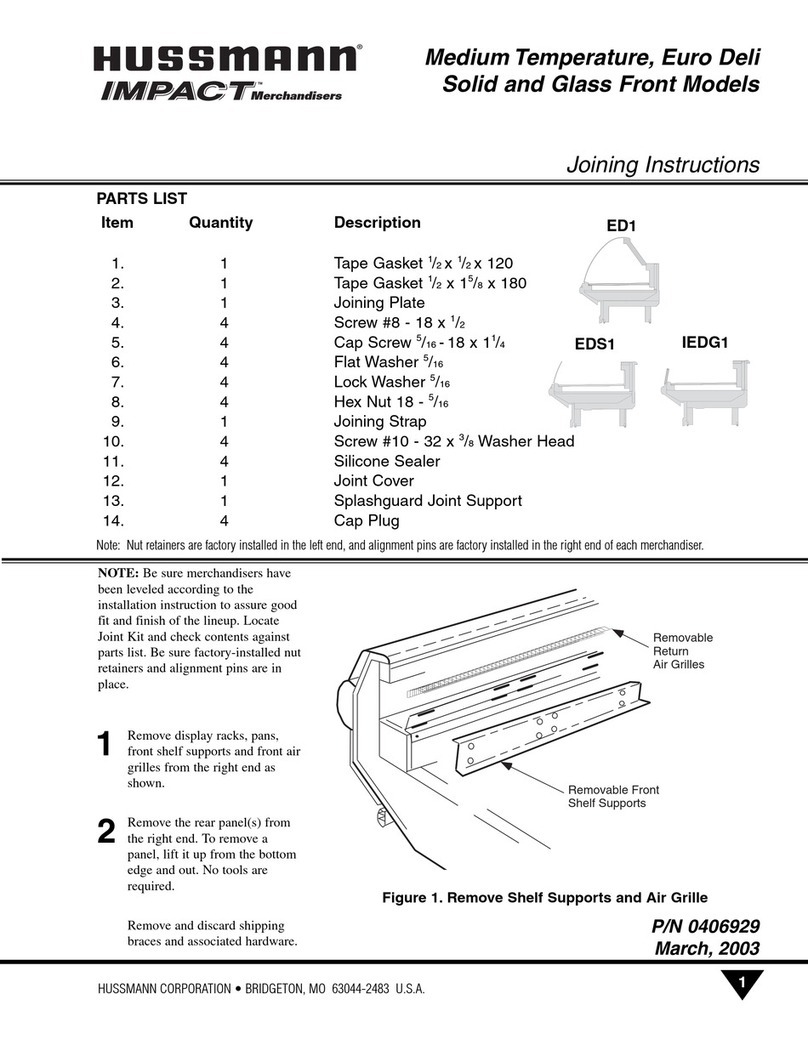

Hussmann IMPACT ED1 User manual

Hussmann

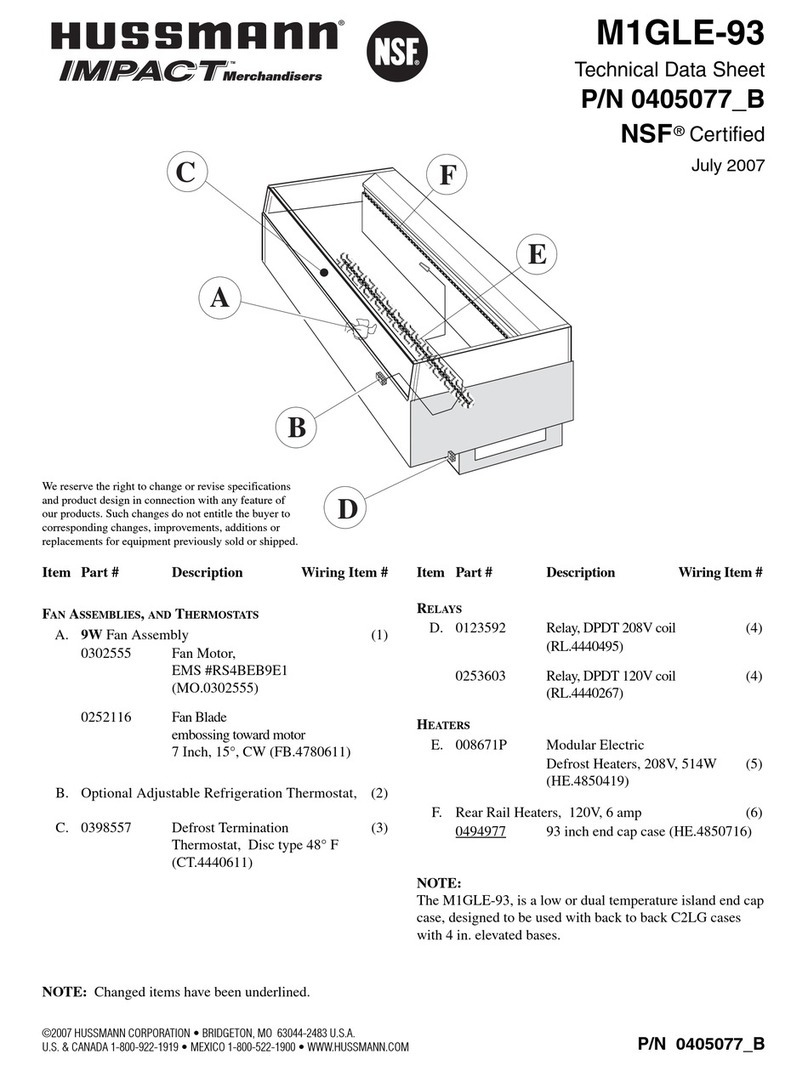

Hussmann Impact M1GLE-93 Instruction Manual

Hussmann

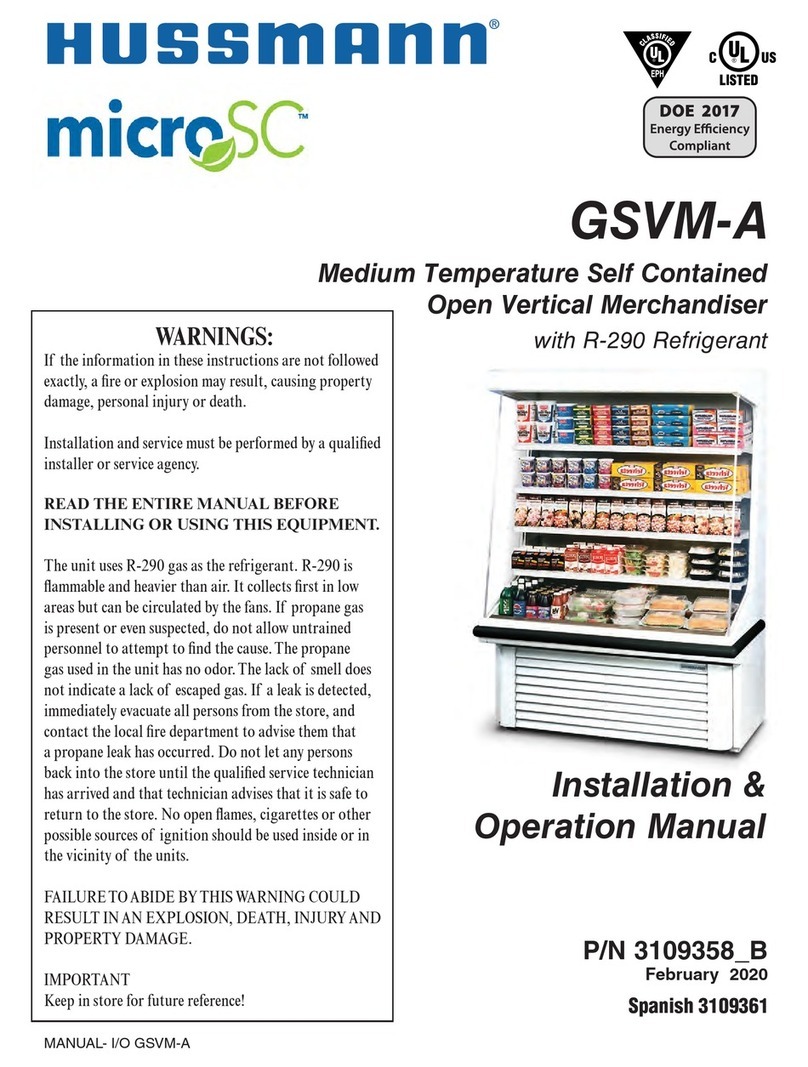

Hussmann microSC GSVM A Series User manual

Hussmann

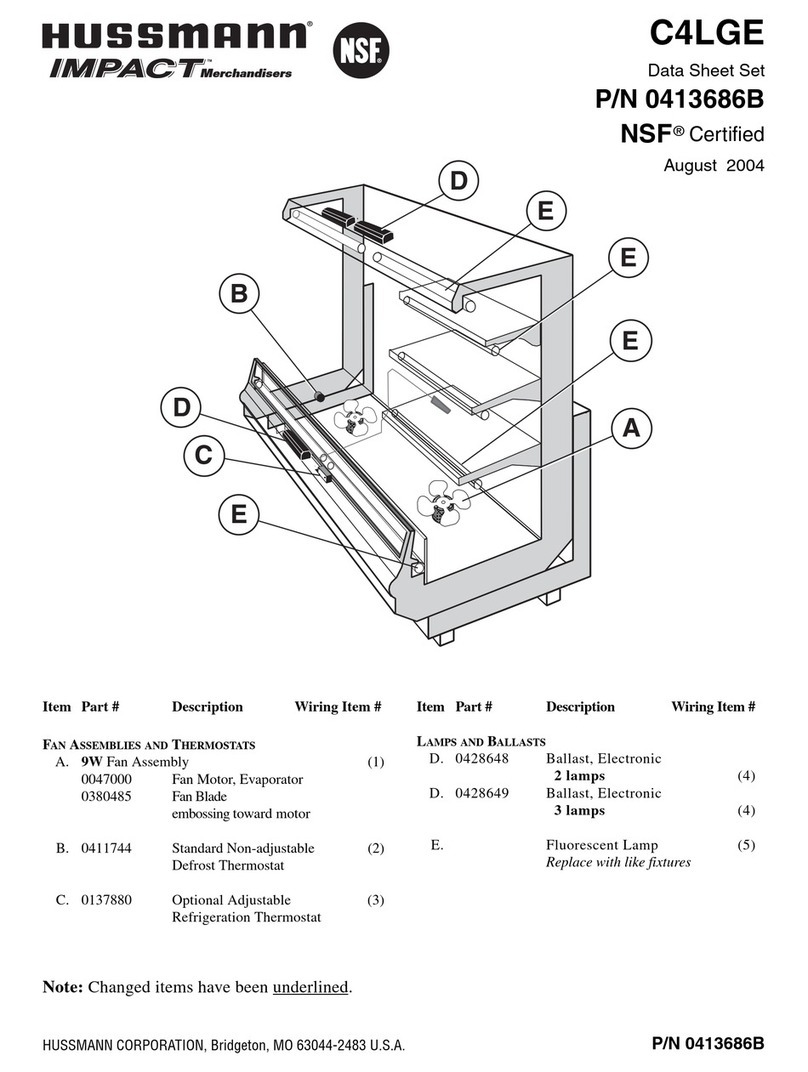

Hussmann impact C4LGE User manual

Hussmann

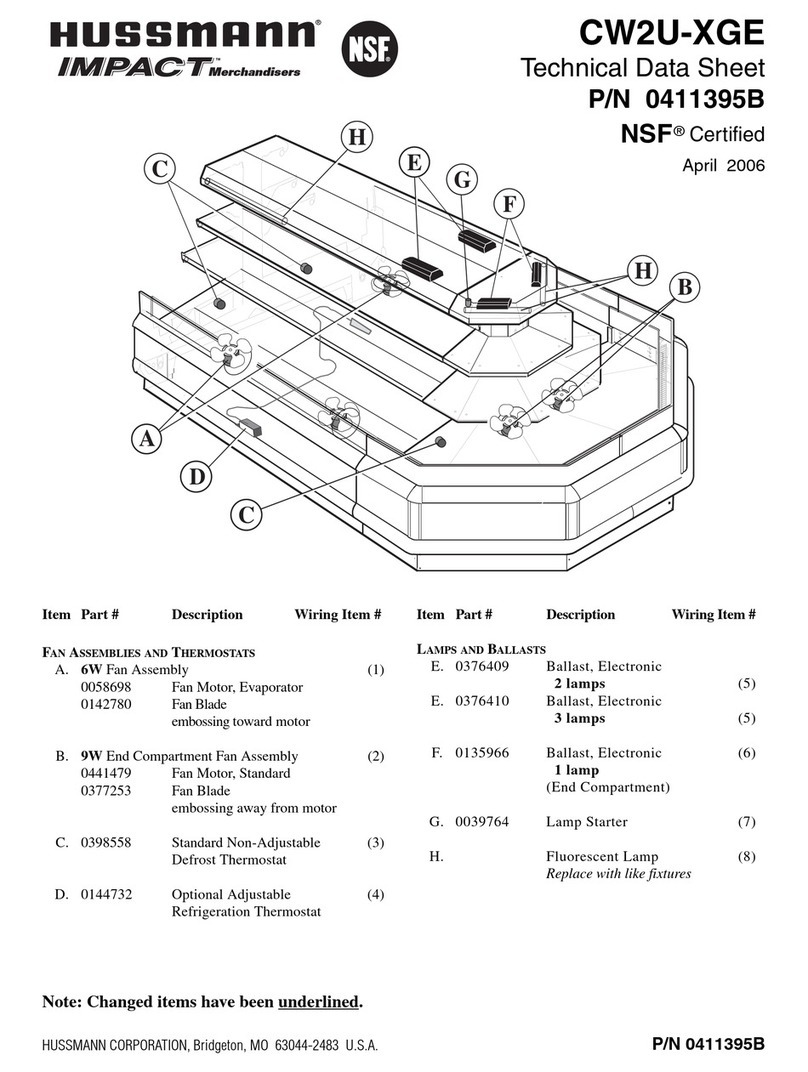

Hussmann IMPACT CW2U-XGE Instruction Manual

Hussmann

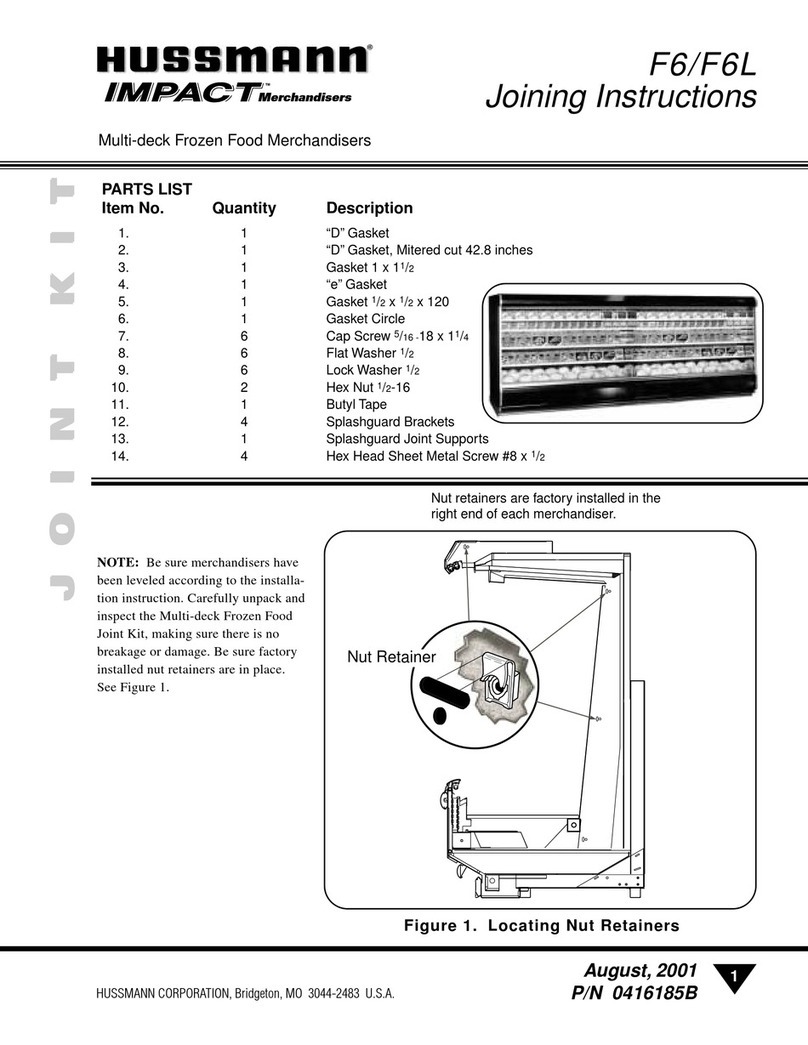

Hussmann Impact F6 User manual

Hussmann

Hussmann IMPACT D6 User manual

Popular Merchandiser manuals by other brands

FRIGOGLASS

FRIGOGLASS Flex 20 HC user manual

EPTA

EPTA COSTAN RHINO MULTI User instructions

CASCO

CASCO Nano Cube owner's manual

True

True GDIM-26 installation manual

Structural Concepts

Structural Concepts Oasis Mobile Series Installation & operating manual

Haussmann

Haussmann RL Installation & operation manual

Howard McCray

Howard McCray R-CDS32E-4 Specifications

EPTA

EPTA iarp Cool Emotions Delight Lite User instructions

VALERA

VALERA BC 85 datasheet

HL Display

HL Display 3eBin Assembly instructions

Dixie Narco

Dixie Narco DNCB 501E Technical manual

APW Wyott

APW Wyott Racer DMXD-30H Installation and operating instructions

Hoshizaki

Hoshizaki KD-90C Service manual

Summit

Summit SCR1006 instruction manual

Delfield

Delfield Shelleyspeed SPM-28E Specifications

EPTA

EPTA iarp Cool Emotions GLEE 40 User instructions

Kysor/Warren

Kysor/Warren GranBering KW TECHNICAL MANUAL & USER INSTRUCTIONS

Crane

Crane BevMAX Refresh 6 Media Operation guide