VII Maintenance

1、The machine should be used by an experienced operator. The

operator must read this manual carefully before operating.

2、Keep work area clean. Paint rust-proof oil on un-painted section and

sliding section of the machine.

3、Keep shearing blade edge sharp. If you find any damage or wear or

bull, please re-grind the blade or change a new blade. And it is avoid

to shear and cut the broken material which is too thick or the material

with rigid scar、residue、welding line、damaged edge and so on.

4、Please use clean and anti-corrosive lubrication oil.

5、Operate the machine exactly according to operation manual. Don’t

overload the capacity of the machine to avoid the damage to the

machine parts or blade.

6、At working, should any abnormal circumstance happened, the

operator must stop the working at once. Then turn the power off,

inspect the reason by a qualified technician.

7、When finishing the work, please turn the power off, and clean the

machine.

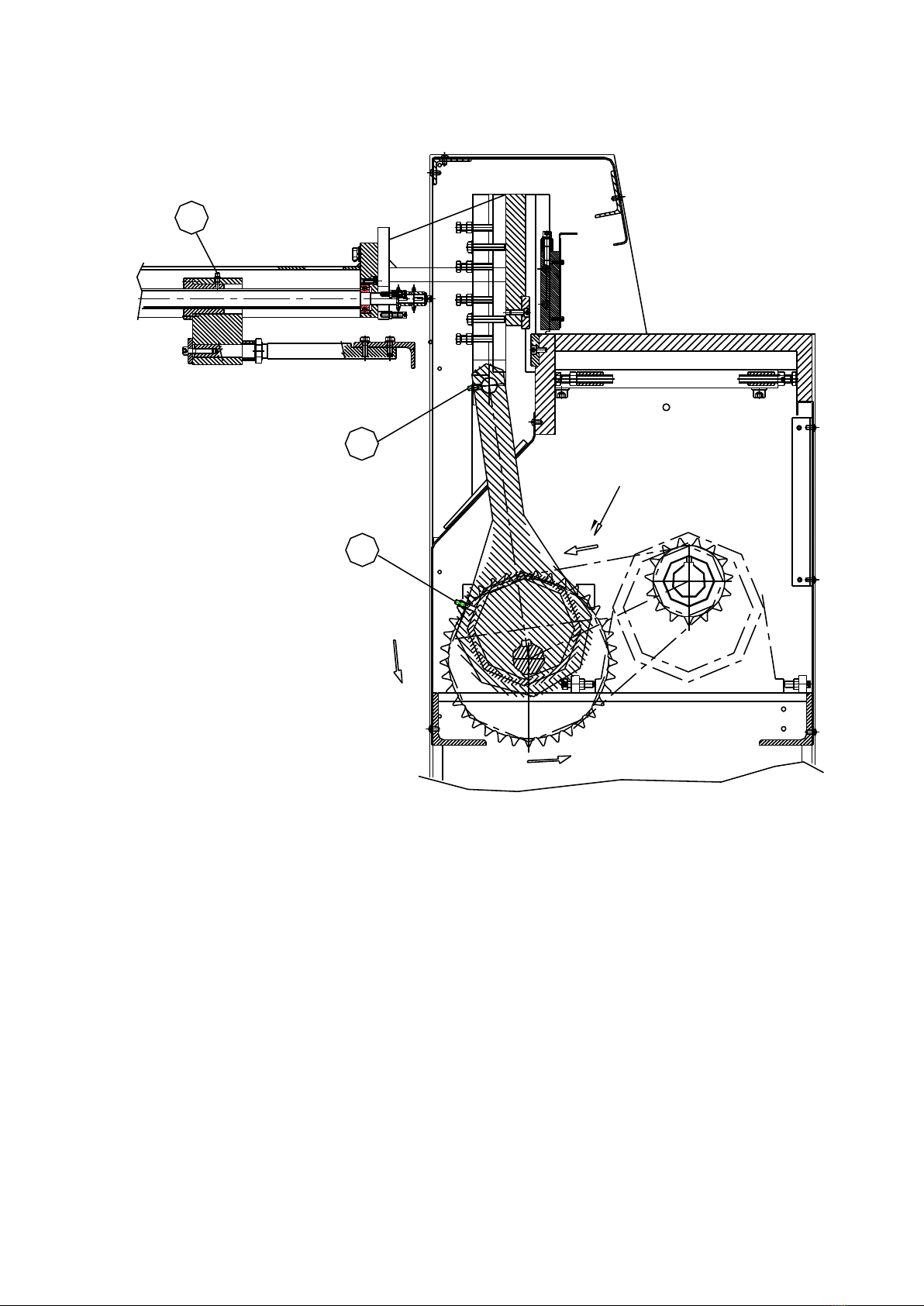

8、Inspect the electric system periodically. After inspection and repair on

the gear reduction motor, please carefully check the rotating direction

and speed are right.