3. Purpose and Structure of Machine

The universal swivel head milling machine is designed for milling on general

metal workpiece.

Warning: Do not process flammable and explosive metal, e.g. pure

aluminum and magnesium, etc.

The universal swivel head milling machine consists of universal swivel head,

base, column, knee, table, revolving bed, main drive structure, feed box, ram,

coolant, lubrication, electrical system and so on.

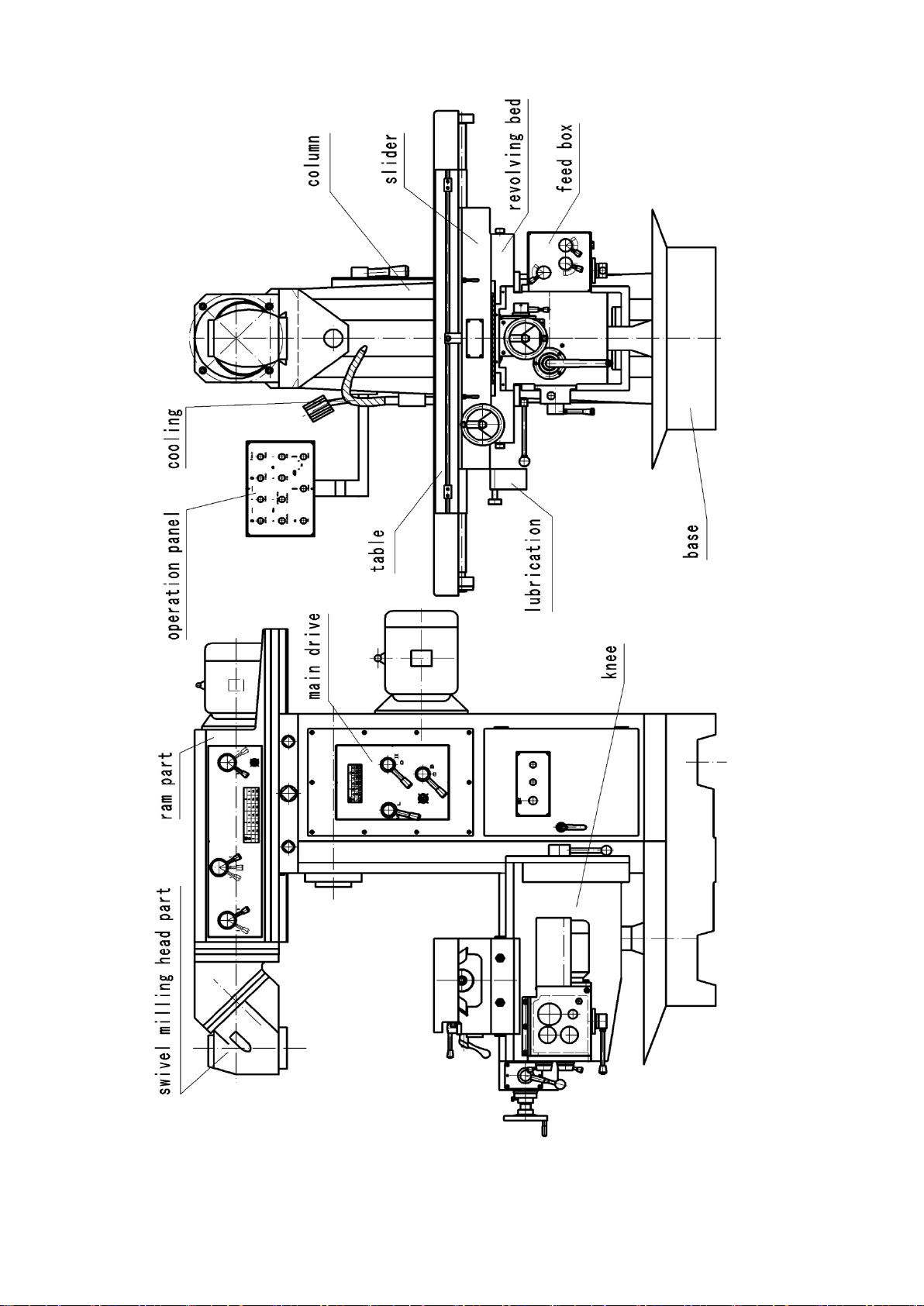

The structure of the machine: (Figure.1)

3.1 The column is fixed on the base with screws.

3.2 Knee is in front of the column, and connects with the column through

rectangular guideways, which can rise and lower along vertical guideway.

3.3 Revolving bed connects with knee through rectangular guideways. Table

connects with slide through dovetail guideways. Worktable and the slide can be

moved through lead screw and nut.

3.4 Main transmission adopts gears drive structure.

3.5 The feed box is fixed at the bottom & right of revolving bed, and it is driven

directly by motor,

3.6 The coolant system consists of coolant pump, cooling tube and tank in the base

and so on.

3.7 Lubrication system consists of oil immersed splash lubrication, lubrication pump

and hand pump and so on.

3.8 Operation panel is on the left of the column, which enables convenient

operation.

The table is moved by hands or power, the power of feed box is provided by

only one motor. The feed box has twenty-four kinds of speed steps and three kinds

of rapid speed. Main transmission adopts gears structure, high efficiency, big torque,

enlarges speed change range, so enlarge the machining range.

3.9 Rotation of table: Loosen the four screws at two sides of the revolving bed, then

turn the table forcibly in target position.