These instructions apply to 1½ hour rated fire dampers mounted in steel stud walls. Specific requirements in these

instructions are mandatory. These instructions meet the requirements of UL555. Installation shall comply with the

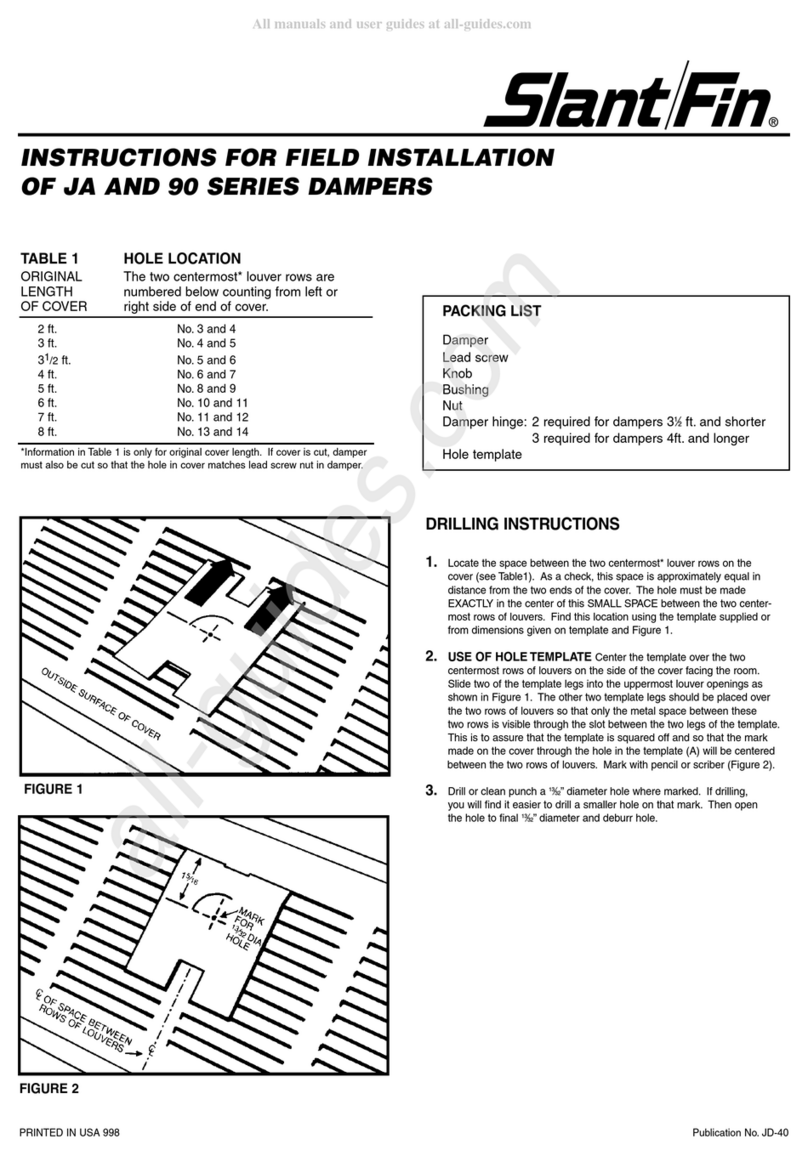

requirementsofNFPA90AStandardfortheInstallationofAirConditioningandVentilatingSystems.U.L.listings

R13317andR13743,CaliforniaStateFireMarshallistings3225-981:102and3225-1241:101,andNewYorkCityBSA/

MEAlisting260-91-Mastheyapplytothesedampers.

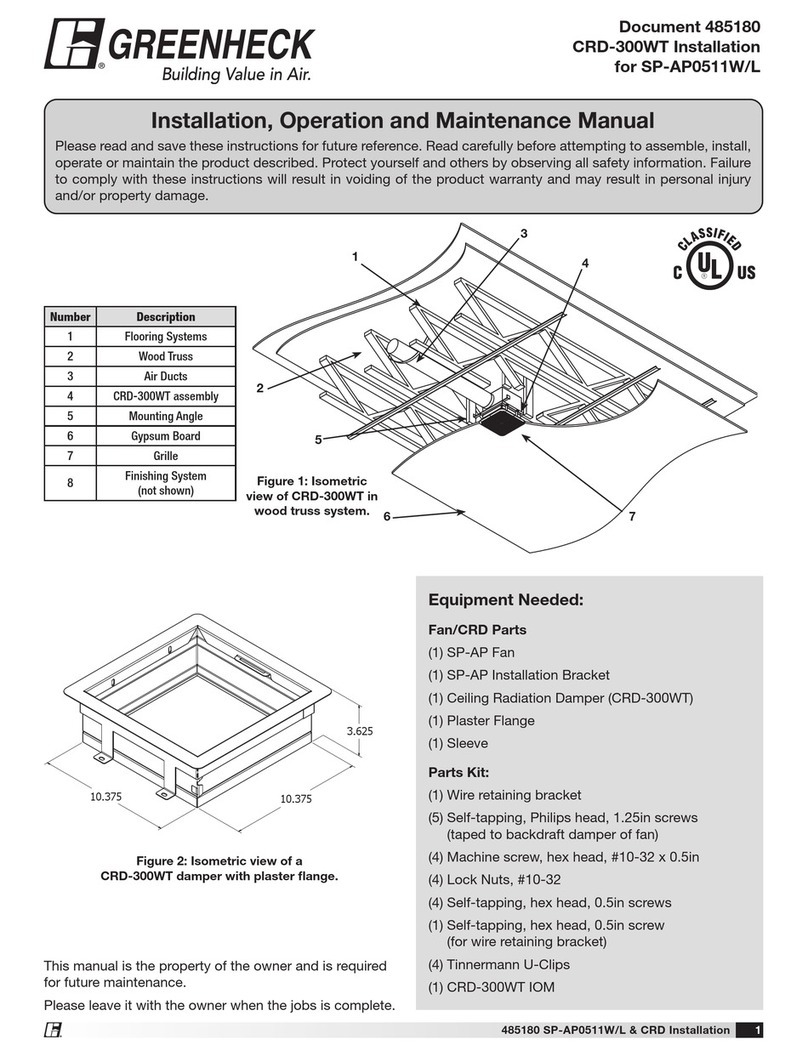

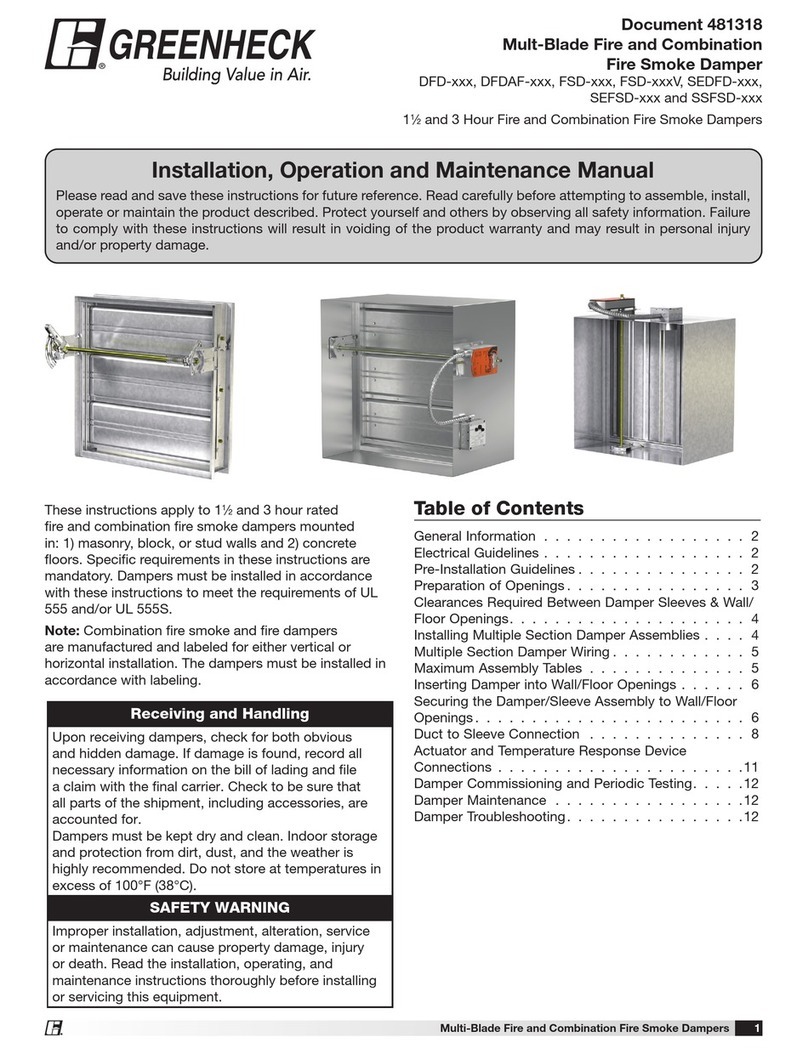

Installation for Steel Stud Connection (SSC) Option

6

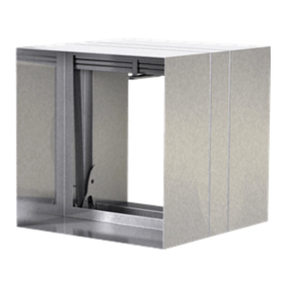

1. NO ADDITIONAL SLEEVES OR ANGLES ARE

REQUIRED

The fire damper extended frame is an approved sleeve

and the Steel Stud Connection (SSC) Option allows

fastening of the fire damper sleeve directly to the

wall's steel stud framing. Damper frame shall extend

amaximumof6in.(152mm)beyondthewallopening

oneitherside.Maximumsizefiredamperthatmaybe

installedusingthisSSCoptionis36in.Wx36in.H

(914mmx914mm).

2. INSTALLATION

Fire damper with SSC option must be in place before

the wall is constructed or it can be installed as the wall

is being constructed. Wall opening is framed around

the fire damper before sheet rock or other wall board

material is applied to the steel studs. This installation

provides appropriate protection for duct penetrations

in fire resistant wall construction using steel studs with

a fire resistance rating less than 3 hours. The following

wall design numbers (as detailed in the UL Fire

Resistance Directory) are appropriate for fire damper

installations using this SSC option:

1HourDesign:U405,U406,U422,U434,U448,U451,

U456,U457,U465,U468,U469,U485,U494

1½HourDesign:U449,U452,U470,U471

2HourDesign:U403,U411,U412,U421,U425,U428,

U429,U443,U453,U474,U475,U477,U484,U491,

U495

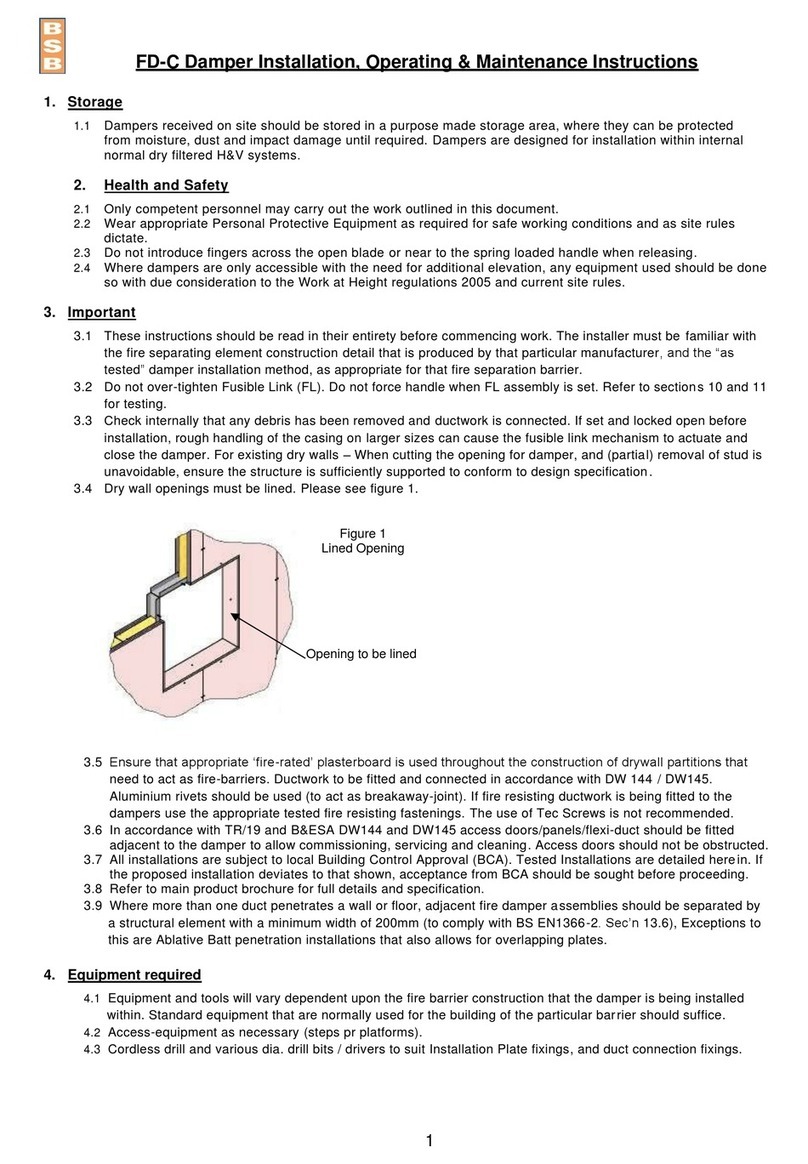

3. FRAMING OF WALL OPENING

Formawallopening1/8in.(3mm)to1/4in.(6mm)

larger than the OD of the fire damper's extended frame

(sleeve) using the same metal studs and techniques

required by the wall design per the UL Fire Resistance

Directory. Open side of the steel stud channels shall

face the fire damper and encompass the damper's

retaining bar.

4. APPLY WALLBOARD AFTER DAMPER

INSTALLATION

Afterdamperisinstalled,wallboardshallbeapplied

to steel stud framework in the manner required by

the wall design per the UL Fire Resistance Directory

listing.Aroundthedamperperimeteruseaminimum

of 2 connections per side, spaced 12 in. (305mm)

maximum and located a maximum of 2 in. (51mm)

from each corner. No additional retaining angles are

required to complete the installation.

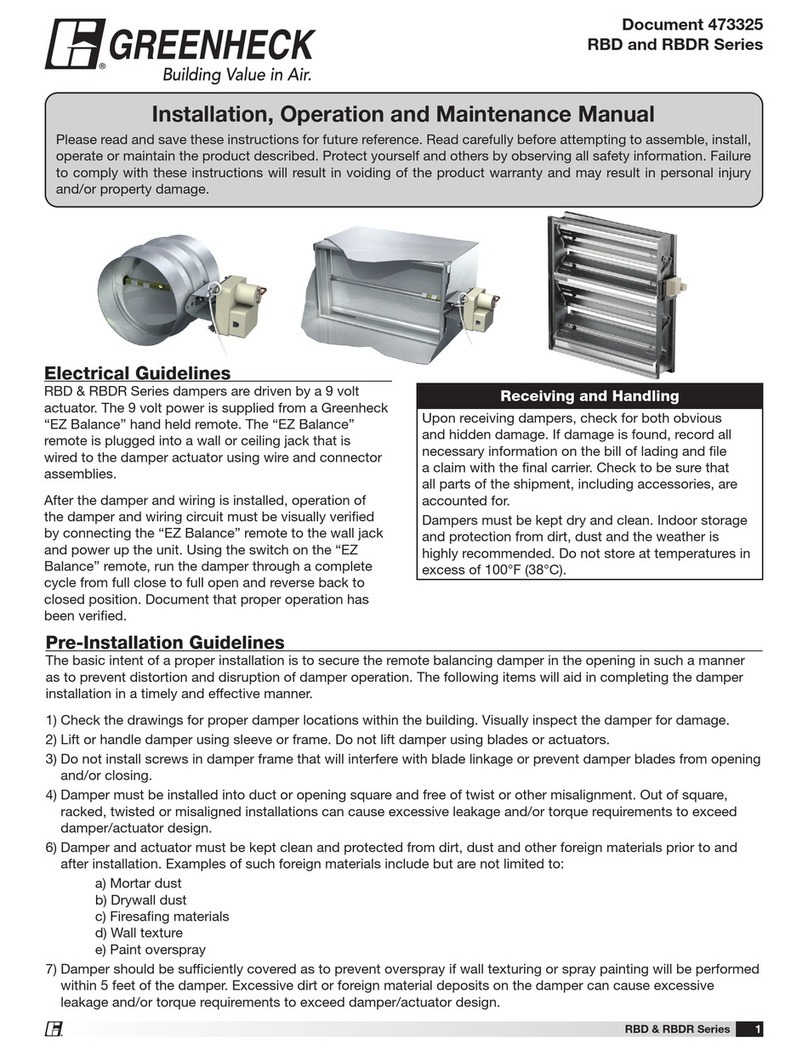

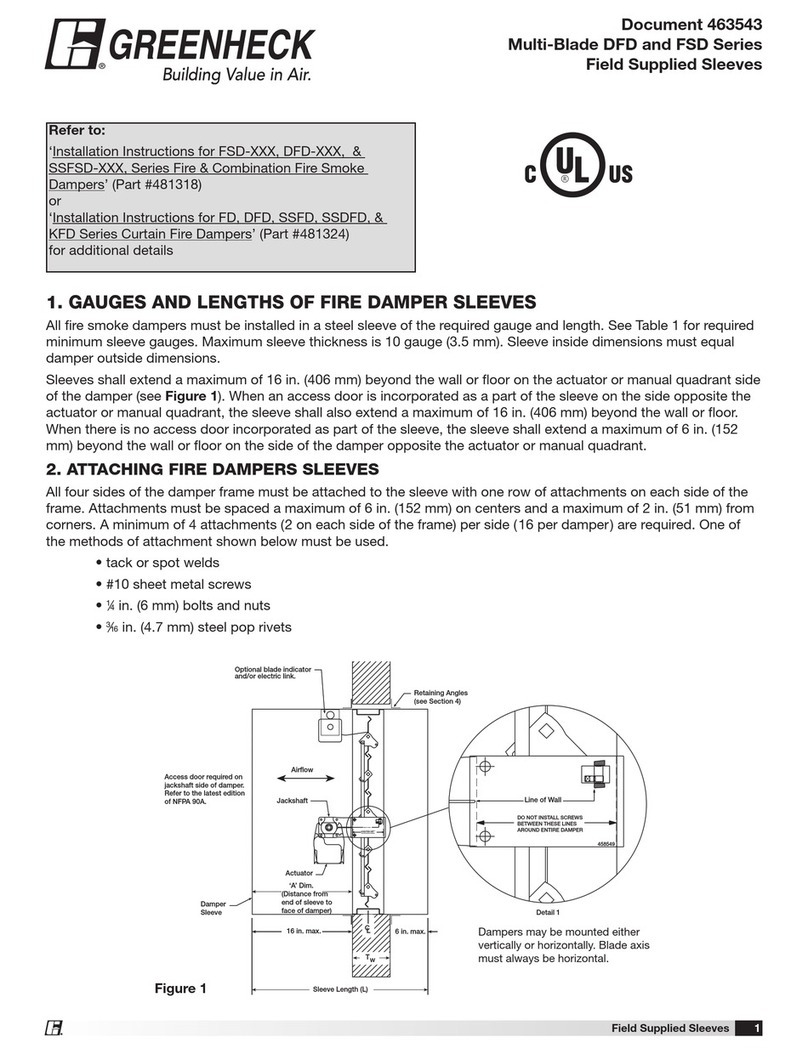

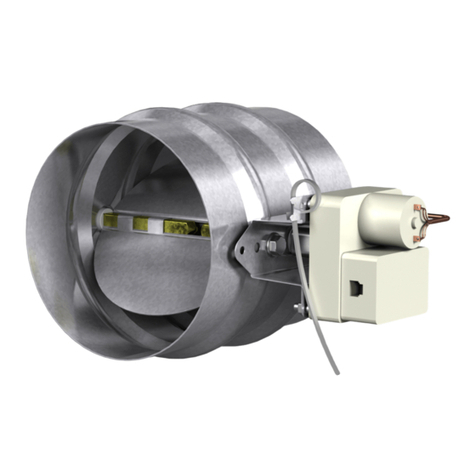

5. CONNECTING DUCTS TO THE FIRE DAMPER

AllductconnectionstoFD&DFD150Xseries

extended frame dampers must be “breakaway” type

connections.Allconnectionsshownonpage5&6are

considered breakaway. Factory furnished duct collars

ontypesR,CR,&COfiredampersarealsoconsidered

breakaway.

(TDC by Lockformer, TDF by Engle)

TDCandTDFsystemsareapprovedasbreakawayconnectionswheninstalledasdescribedintheSMACNADuct

ConstructionStandards.Standard6in.metalclipsmaybeusedwithspacing(seeFigure 8). Three-eighth in. metal

bolts and nuts may be used to fasten together corner pieces (see Figure 9).

Figure 8: Detail of proprietary flanged system breakaway

connections.

Figure 9: Detail of bolted corner.

$UCT

3LEEVE

IN

3TD#LIP

,ENGTH

#

,

$UCT

IN$UCT

2EQD

IN$UCT

2EQD

IN$UCT

2EQD

IN$UCT

2EQD

IN$UCT

3MALLER

2EQD

#LIP3PACING

4YPICAL4$#4$&JOINT

IN IN

IN

ININ

IN IN

ININ

Duct End

Flange

Corner Piece

3/8 in. bolt

(optional)