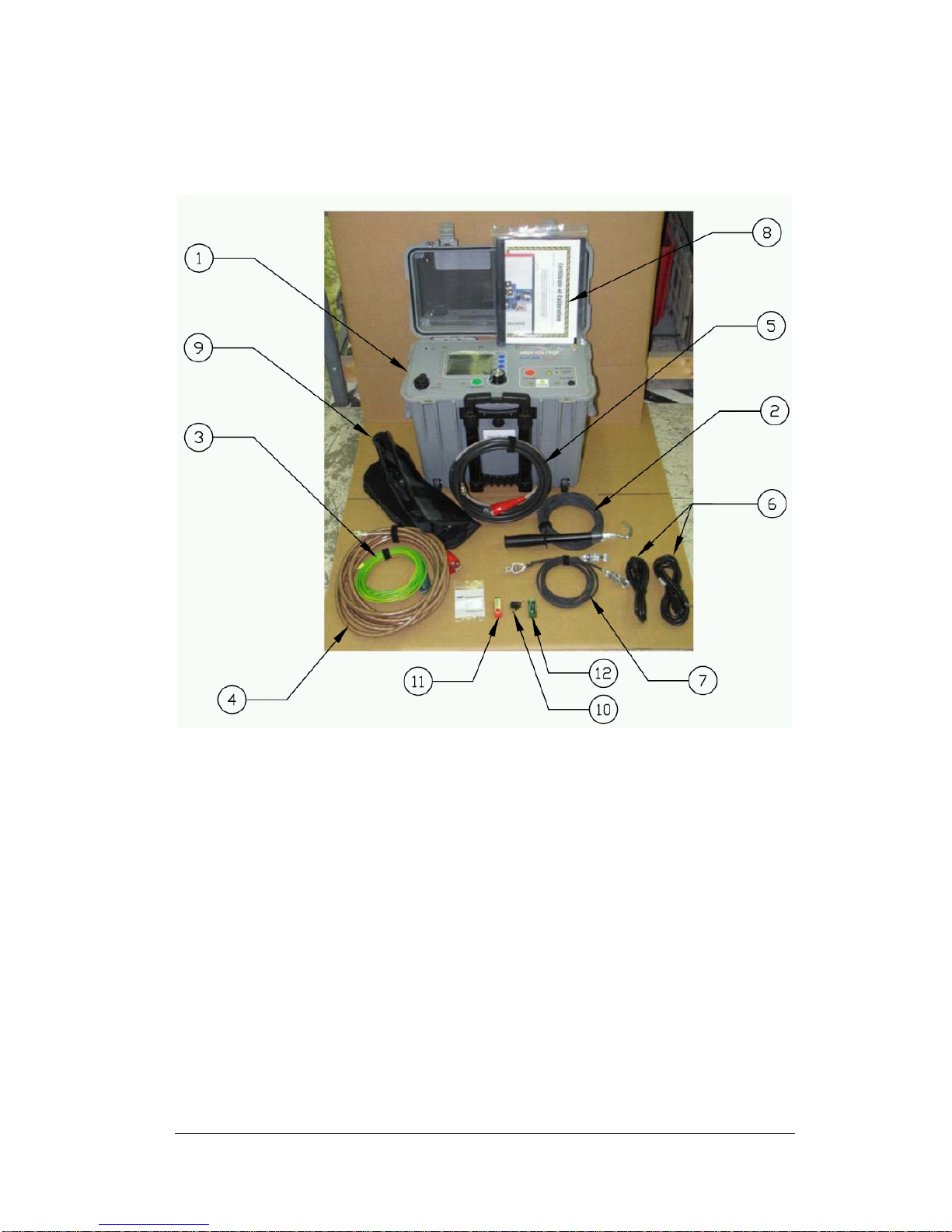

OPERATOR MANUAL

GeneralInformation

Thissectionfamiliarizestheoperatorwiththefeaturesandspecificationsof the

VLF-34E AC Hipot manufacturedbyHIGH VOLTAGE, INC.

FeaturesandSpecifications

Input Voltage: 115 Vac – 230 Vac, 50 Hz/60Hz, 5A max

Input Fuse: 5x20mm, 250Vac, TypeF

2.5A-250V Input

5.0A–120V Input

HV Output:

0-34 kVac peak/0-24 kVac rms – Sinusoidal

DC: +/- 34 kV

Square wave: 34 kV

Sheath Tester

Voltage Measurement Range 1 - 34 kV peak/1 - 25 kV rms

Accuracy & Resolution 1% & 0.1 kV peak

Current Measurement Range 0 - 15 mA rms

Accuracy & Resolution 1% & 1 μA

Duty: Continuous

Frequency: 0.1 Hz to 0.01 Hz

Load Rating:

0.5 uF @ 0.1 Hz @ 34 kV

1.0 uF @ 0.05 Hz @34 kV

5.0 uF @ 0.01 Hz @34 kV

uF rating increases at lower voltages

Ex: 0.77 uF @ 0.1 Hz @ 22 kV peak

Metering: Voltage kV peak or RMS