BEAMEX MCS100 User manual

Instruction manual for

MODULAR CALIBRATION SYSTEM

Beamex®MCS100

Dear user,

We have made every effort to ensure the accuracy of the

contents of this manual. Should any errors be detected, we would

greatly appreciate to receive suggestions to improve the quality of

the contents of this manual.

The above not withstanding, we can assume no responsibility for

any errors in this manual or their eventual consequences.

We reserve rights to make modifications to this manual without

any further notice.

For the Beamex®MC5P Calibration host module, please refer to

separate user guide.

© Copyright 2011

BEAMEX OY AB

Ristisuonraitti 10

FI-68600 Pietarsaari

FINLAND

Tel +358- 10-5505000

Fax +358-10-5505404

Internet: http://www.beamex.com

8889000 / UEMCS100 / 000696

Trademarks

QCAL®is a registered trademark owned by Beamex Oy Ab.

Other trademarks are property of their respective owners.

Contents

Part A, About the MCS100 System

General Overview 2

Introduction …………………………………2

Unpacking and Inspection …..……………3

Service …………………………..………….3

Safety 4

The MCS100 Desktop System power

supply …………….……..……………….…5

MCS100 Desktop System 6

General ………………………..……………6

Environmental Specification ……..……6

Taking the Desktop System in use 7

Uninstalling and Installing Modules

in the Desktop System ……………..……..8

Internal Connections …………………...9

MCS100 Bench System 10

General ……………………………………10

Environmental Specification ……..….10

High Workstation …………………………10

Assembly Instructions for High

Workstations …………………………..11

Corner Unit ………………………………..13

How to Assemble the Corner Unit …..14

Low Workstation …………………………16

Assembly Instructions for Low

Workstations …………………………..16

Connecting the Workstation to

the Electrical Network ……………………18

Connecting the Workstation to

the Pressure Supply ……………………..18

Use of the Workstation…………………..19

Uninstalling and Installing Modules

in the Bench System …………………….20

Internal connections…………………..21

DS2 Data Switch Module………………..22

Connections……………………………23

Special Workstations …………………….25

Heavy-duty Workstation ……………...25

Electrical Trolley……………………….25

Part B, Main Supply Units

General 27

Warnings ……………………..….…………27

SU1 Main Supply Unit 28

Connections .……………………………….29

Operation …………………………….……..29

Part C, Assisting Modules

General 31

Warnings When Using

Pressure Modules ………………………..32

Additional Warnings When Using

High Pressure Modules ………………….33

Pressure Connections 34

Pressure Supply Modules 35

PS7 Pressure Supply Module …………..35

Operation ………………………………35

Connections……………………………35

Maintenance of the Pressure

Supply Modules …………………………..36

Pressure Output Modules 37

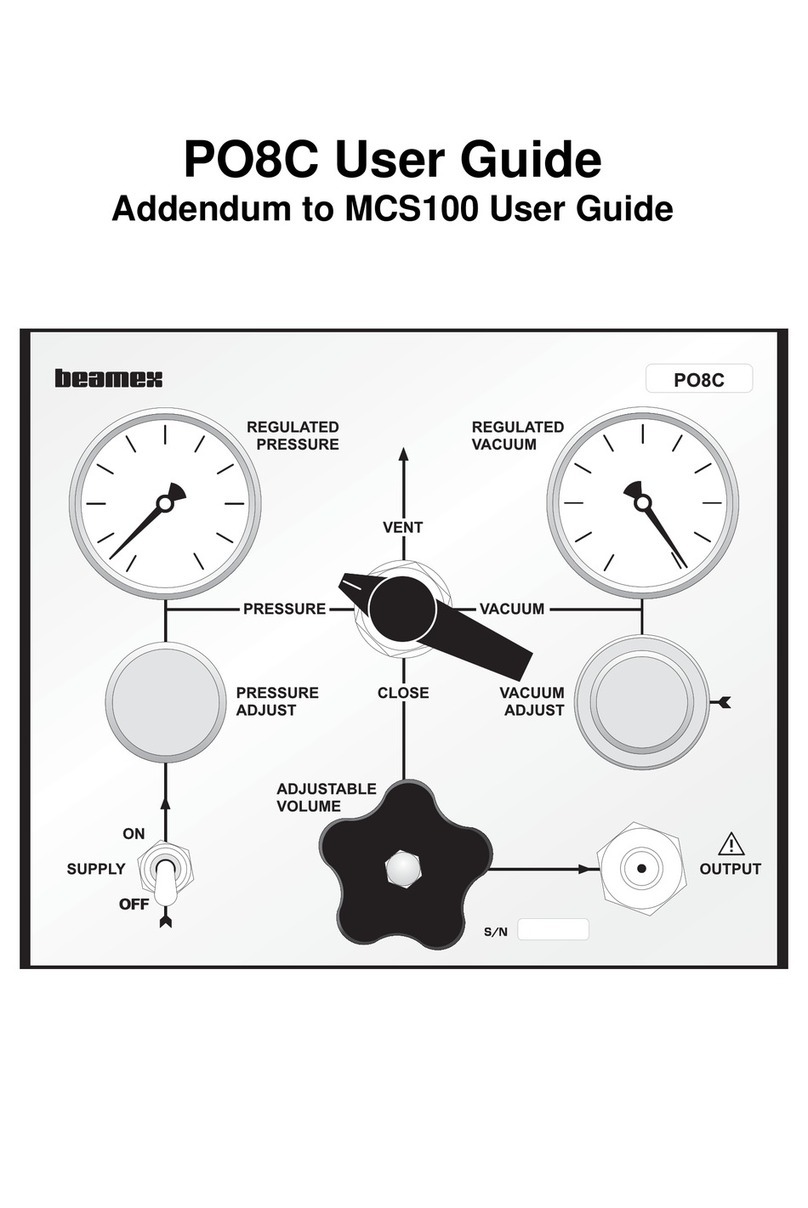

PO8C………………………………………38

Specifications ………………………….40

Warnings……………………………….42

Service …………………………………44

Selector Valve …………………………44

Operation ………………………………44

PO20 ………………………………………46

Operation ………………………………46

Connections …………………………...48

PO60, PO160 and PO250 ………………48

Operation ………………………………49

Connections ...…………………………49

Maintenance of the Pressure

Output Modules …………………………..50

Pressure Measurement Modules 51

Available Pressure Measurement

Module Types and Their

Measurement Ranges …………………….52

Installing and Uninstalling Pressure

Measurement Modules ……………………53

Removing a Pressure

Measurement Module ………………….53

Adding a Pressure

Measurement Module ………………….54

RTS24P Temperature/Resistance

Simulator Module 55

Operation……………………………………56

Installing and Uninstalling

the RTS24P Module……………………….56

Appendixes

Appendix 1,

Compatibility of MCS100

Workbench Table Frames

and Module Racks 58

Appendix 2,

Index 60

MCS100 User Guide 1

About the MCS100 System

Things discussed in Part A:

introduction to what MCS100 is and what the

parts of this User Guide concentrate on,

general presentation of the MCS100 Desktop

System,

general presentation of the MCS100 Bench

System and

how to install and take in use different type of

MCS100 Bench Systems.

MCS100 User Guide 2

General Overview

Introduction

The MCS100 System is a Modular Calibration System for

calibration and maintenance of process instruments, like

transmitters, converters, temperature probes, recorders, indicators,

etc. The system is designed for instrument/electrical workshops and

laboratories.

The MCS100 comprises a Desktop System, a Bench System or an

Electrical Trolley. The modular construction of the system allows

the user to customize the MCS100 System to practically any

measurement and calibration application.

The modules in the MCS100 System can be grouped into four main

types:

1. Host modules (Calibrator modules):

MC5P Calibration host module

2. Assisting modules, divided into:

PO’s, i.e. Manual Pressure Output Modules,

PS’s, i.e. Manual Pressure Supply Modules,

PM’s, i.e. Pressure Measurement Modules and

RTS24P Temperature/Resistance Simulator module

3. POC6 Automatic Pressure Controller

4. Power supplies, measuring instruments, soldering stations and

other modules.

This manual includes a general presentation of the MCS100

System in part A.

Part B concentrates on the Main Supply Units for the MCS100

Bench system.

Part C concentrates on the Assisting modules (PO's, PS's, PM's

and RTS24P)

MC5P Calibration host module, POC6 Automatic Pressure

Controller, Power supplies, Measuring instruments and other

modules are covered in separate manuals.

Note

This manual includes a description of all the MCS100 Modular

Calibration Systems available, not only the system at hand.

MCS100 User Guide 3

Unpacking and Inspection

At the factory each new MCS100 System passes a careful

inspection. It should be free of scrapes and scratches and in proper

operation condition upon receipt. The receiver should, however,

inspect the unit for any damage that may have occurred during

transport. If there are signs of obvious mechanical damage,

package contents are incomplete, or the instrument does not

operate according to specifications, contact the purchasing sales

office as soon as possible.

The Modular Calibration System MCS100 is supplied with a general

instruction manual. The host modules (MC5P), the automatic

pressure controller (POC6), power supplies, measuring instruments

and other modules have their own manuals. All the modules

purchased with the MCS100 System are installed in the module

rack or in the base unit at the factory. Installation of additional

modules that are purchased later on is described in chapter

Uninstalling and Installing Modules in the Desktop System on

page 8 and chapter Uninstalling and Installing Modules in the

Bench System on page 20.

If you have to return a module or another part of the MCS100

System to the factory for any reason, include a detailed description

of the reason for the return.

Service

A module that requires service or calibration must be carefully

packed and should be accompanied with a letter or note with the

following information:

User’s name

User’s address

Module name

Serial number

Description of the problem

If the module requires calibration, it must be stated in the enclosed

letter.

MCS100 User Guide 4

Safety

High voltage is dangerous. Getting into contact with high

voltages can result in serious injuries, even death.

The power cable plug shall only be inserted into a socket

with a protective earth contact in accordance with local

electrical rules. The protective action must not be negated by

the use of an extension cord without a protective conductor

(grounding).

Make sure that only fuses with the required rated current and

for the specified type (normal blow, time delay etc.) are used

for replacement. The use of repaired fuses and the short

circuiting of fuse holders must be avoided.

Capacitors in the power supply unit may still be charged

even if the power cable has been disconnected.

Sometimes it is necessary to carry out measurements inside

the module rack with the mains power on. Make these

measurements with extreme care and remove the power

cable immediately after the measurements are completed.

The operation should be carried out by a skilled person who

is aware of the hazard involved.

In the occasion that a module is no longer operating safely,

the module must be taken out of use and precautions must

be taken against accidental use

Safe use is no longer possible in the following cases:

- When the module has a clear visible damage

- When the instrument is not functioning as expected

- After prolonged storage in unfavorable conditions

- After serious damage during transport

Warnings concerning pressure modules are presented in part C of

this manual.

MCS100 User Guide 5

The MCS100 Desktop System power supply

The following data is for the power supply used in MCS100 Desktop

Systems.

Input 110 … 240 V, 50/60 Hz

Output 12 V DC 3.8 A

MCS100 bench systems and electrical trolleys utilize the Main

Supply Units described in section B in this manual.

MCS100 User Guide 6

MCS100 Desktop System

General

The base unit of the MCS100 Desktop System contains the cabinet

with a 19” frame for the modules, mains power supply, instrument air

supply and necessary connectors on the rear panel.

In the base unit virtually any

combination of the host modules and

assisting modules can be installed.

The base units come in two heights: BU4 and BU8.

Environmental Specification

Operating temperature 0°C to +40°C (32°F to 104°F)

Storage temperature -20°C to +60°C ( -4°F to 140°F)

Pressure media Clean, dry and oil free instrument air

Conforms to the EMC directive 89/336/EEC and the Low Voltage

Directive 72/23/EEC as attested by conformity with the following

harmonized standards:

Product Standard EN 61326

Safety Requirements EN 61010-1

MCS100 User Guide 7

Taking the Desktop System in use

Connect the mains to the MCS100. Switch on the MC5P host

module and check if it goes through its self test successfully. Switch

on possible other modules with a mains switch.

If any problems appear during the startup, please contact the

manufacturer or your local representative

Connect the pressure supply to the rear of the station. Pressure

supply is required for pressure output modules. Please observe the

following requirements before connecting the pressure supplies.

Instrument air supply

The calibration station requires clean, dry and oil free instrument air

supply. Filtering of the pressure supply is included in the base unit.

Maximum allowed supply air pressure is 10 bar gauge (145 psi).

The filter may be located according to user’s needs, but it needs to

be part of the pressure supply system at all times.

To minimize the danger of flying fragments in the event of a plastic

bowl failure, DO NOT REMOVE THE METAL BOWL GUARD of

the supply air filter. Certain compressor oils, chemicals, solvents,

paints and fumes can cause plastic bowl failure. Depressurize the

unit before removing the metal guard and bowl for service.

High pressure supply

For high pressure output modules there’s a separate supply input

connection. The maximum supply pressure is stated on the back

panel of the MCS100. For the PO20 pressure output module the

maximum supply pressure is 230 bar (3500 psi). For the pressure

output modules PO60, PO160 and PO250 the maximum supply

pressure is 400 bar (6000 psi).

High pressure is always dangerous! Read carefully the

warnings presented in Part C of this manual.

MCS100 User Guide 8

The rear panel of the MCS100 Desktop System.

H I G H P R E S S U R E S U P P L Y

M A X 2 3 0 b a r / 3 5 0 0 p s i

T y p e n r : 1 6 0 1

2 3 0 V ~ 5 0 H z

1 6 0 V A M A X

F u s e 2 * T 1 6 0 m A 2 5 0 V

V e r s i o n : A

M a d e i n F i n l a n d

C o m p / P r t E X T

7 b a r ( 1 0 b a r m a x . )

1 0 0 p s i ( 1 5 0 p s i m a x . )

f r o m d r y o i l f r e e

i n s t r u m e n t a i r s u p p l y

V A C U U M

S U P P L Y

The high pressure warning sign is on view only if a high pressure

output module is included in the Calibration Station. The max.

pressure supply values depend on the range of the pressure output

module.

Uninstalling and Installing Modules in the Desktop System

Warning!

Disconnect the mains cable and the pressure supply to your

MCS100 before you install or uninstall any modules.

The module uninstallation/installation must be carried out by

personnel qualified for electrical and pneumatic installations.

Refer to chapter Safety on page 4 for more specific information

on precautions during installation and uninstallation of

modules.

Before you uninstall any modules from the MCS100, the following

preoperations should be done:

Disconnect the mains supply from the MCS100.

Disconnect the supply pressure from the MCS100.

Disconnect the vacuum supply (if in use) from the MCS100.

Dismount the rear panel plate of the MCS100 chassis by opening

the four screws.

If your Desktop System is a BU8 Base Unit (it has modules

stacked on each other), the rear panel consists of two metal

plates, each fastened with four screws. In that case, dismount all

of the plates.

To uninstall a module

Disconnect all the cables and tubes connected from the module

to be uninstalled to the rear panel. Refer to the picture of internal

connections below.

Open the screws in the front plate of the module to be uninstalled

(four or more screws, depending on the module).

Pull out the module.

Installing a module requires opposite steps.

MCS100 User Guide 9

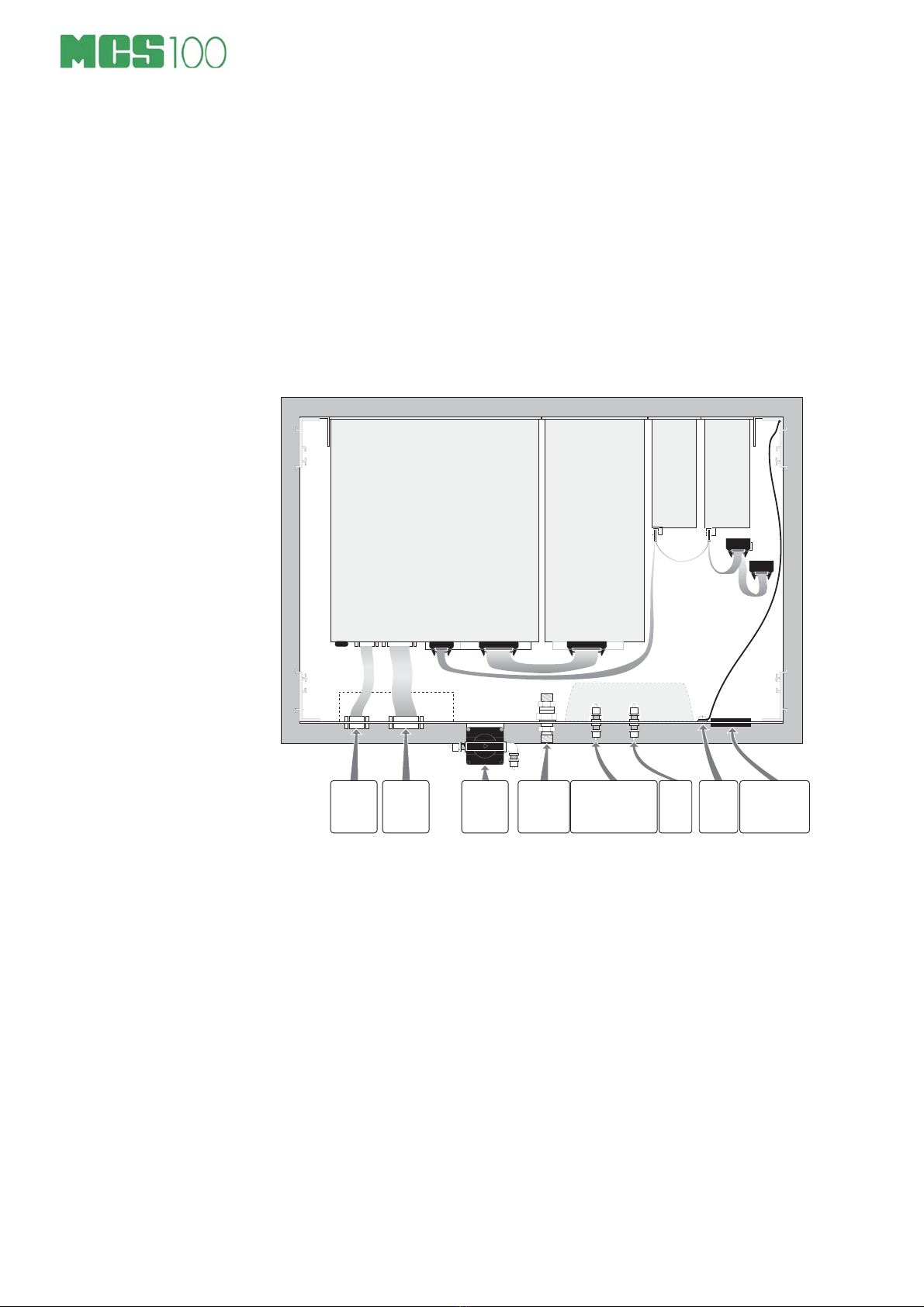

Internal connections

As the internal connections inside an MCS100 Desktop System

depend on the modules installed, it isn’t possible to present all the

combinations. The following picture is an example of internal

connections with an MC5P host module, and ET Module and two

pressure measurement modules. For readability reasons, the

internal pressure supply connections as well as the internal power

supply connections are not shown. Another picture of internal

connections is on page 21 in chapter Uninstalling and installing

modules in the Bench System.

1 0 p i n l a t t a 2 0 p i n l a t t a

9 p i n 1 5 p i n 2 0 p i n l a t t a

R e a r p a n e l

F r o n t p a n e l

M C 5 P

H o s t M o d u l e

P r e s s u r e

m e a s u r e -

m e n t

m o d u l e 1

P o w e r

C o m p / P r t A U X

P r e s s u r e

m e a s u r e -

m e n t

m o d u l e 2

M C 5 P

E T M o d u l e

P r e s s u r e

m e a s u r e m e n t

m o d u l e

d a t a l i n k

E T m o d u l e

d a t a l i n k

S o c k e t o u t p u t s f o r m o d u l e s

r e q u r n g 2 3 0 V / 1 1 5 V s u p p l y

S u p p l y p r e s s u r e

7 b a r ( 1 0 b a r m a x . )

1 0 0 p s i ( 1 5 0 p s i m a x . )

f r o m d r y o i l f r e e

i n s t r u m e n t a i r s u p p l y

H i g h

Pr e s s u r e

S u p p l y

M a x 2 0 0 b a r

3 5 0 0 p s i

V a c u u m

S u p p l y

E l e c t r i c a l

s u p p l y

c o n n e c t i o n

1 0 0 . . . 2 4 0 V A C

C o m p / P r t

( D a t a I / O )

A U X

( O p t i o n s

c o n n e c t o r )

I n s t r u m e n t

a i r f i l t e r

( d e f a u l t

l o c a t i o n )

E a r t h i n g

MCS100 User Guide 10

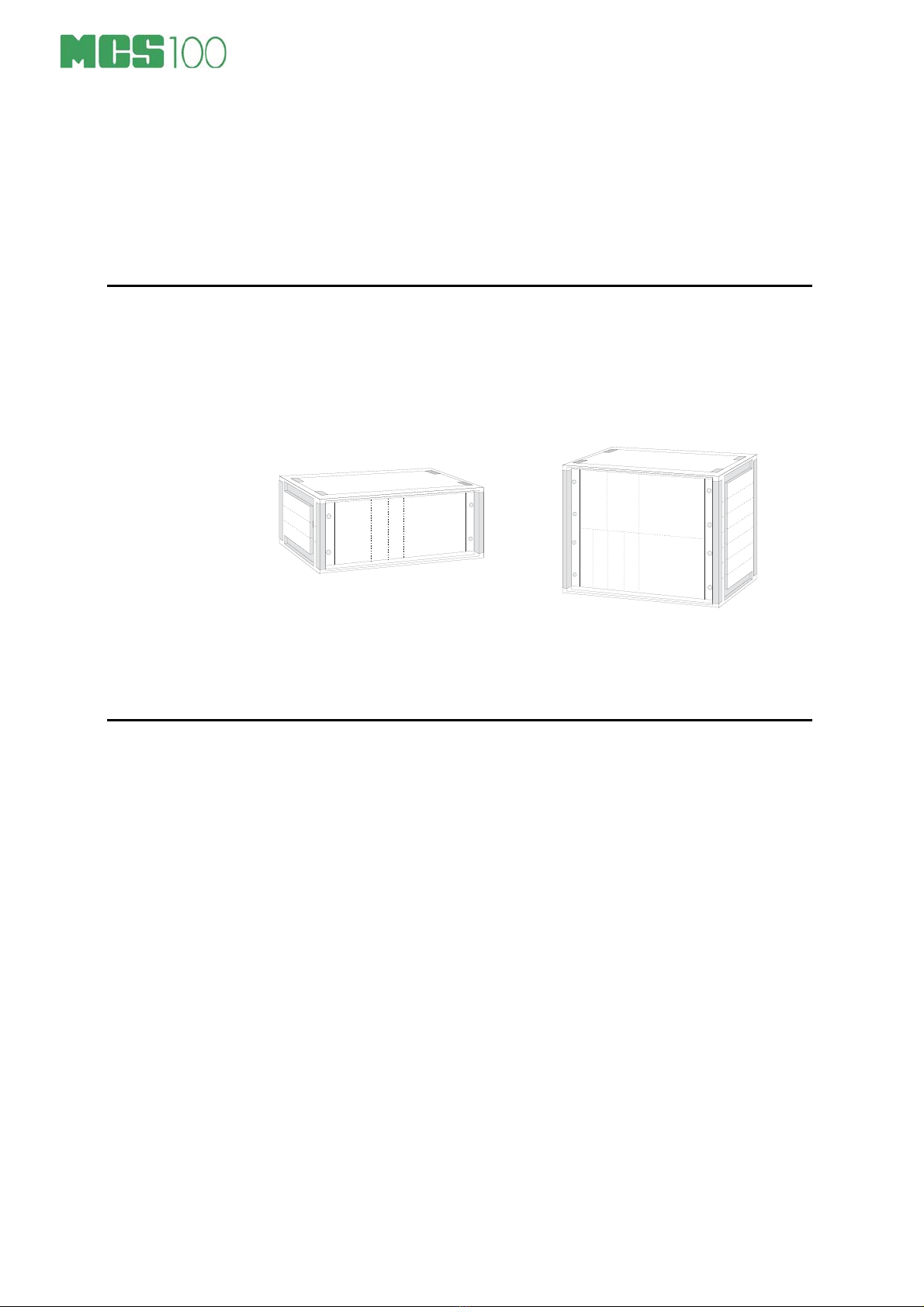

MCS100 Bench System

General

The MCS100 Bench System comes in two models, a High

workstation and a Low workstation. Each workstation comprises

three parts

module rack,

table frame and

table top.

Environmental Specification

Operating temperature 0°C to +40°C (32°F to 104°F)

Storage temperature -20°C to +60°C (-4°F to 140°F)

Protection To IP20

Pressure media Clean, dry and oil free instrument air

Conforms to the EMC directive 89/336/EEC and the Low Voltage

Directive 72/23/EEC as attested by conformity with the following

harmonized standards:

Product Standard EN 61326

Safety Requirements EN 61010-1

High Workstation

In the High Workstation the

module rack is raised above

the table top with a pair of

brackets.

The available widths of the

workstations are:

2030 mm approx. 6 ft 8”

1836 mm approx. 6 ft

1530 mm approx. 5 ft ¼”

MCS100 User Guide 11

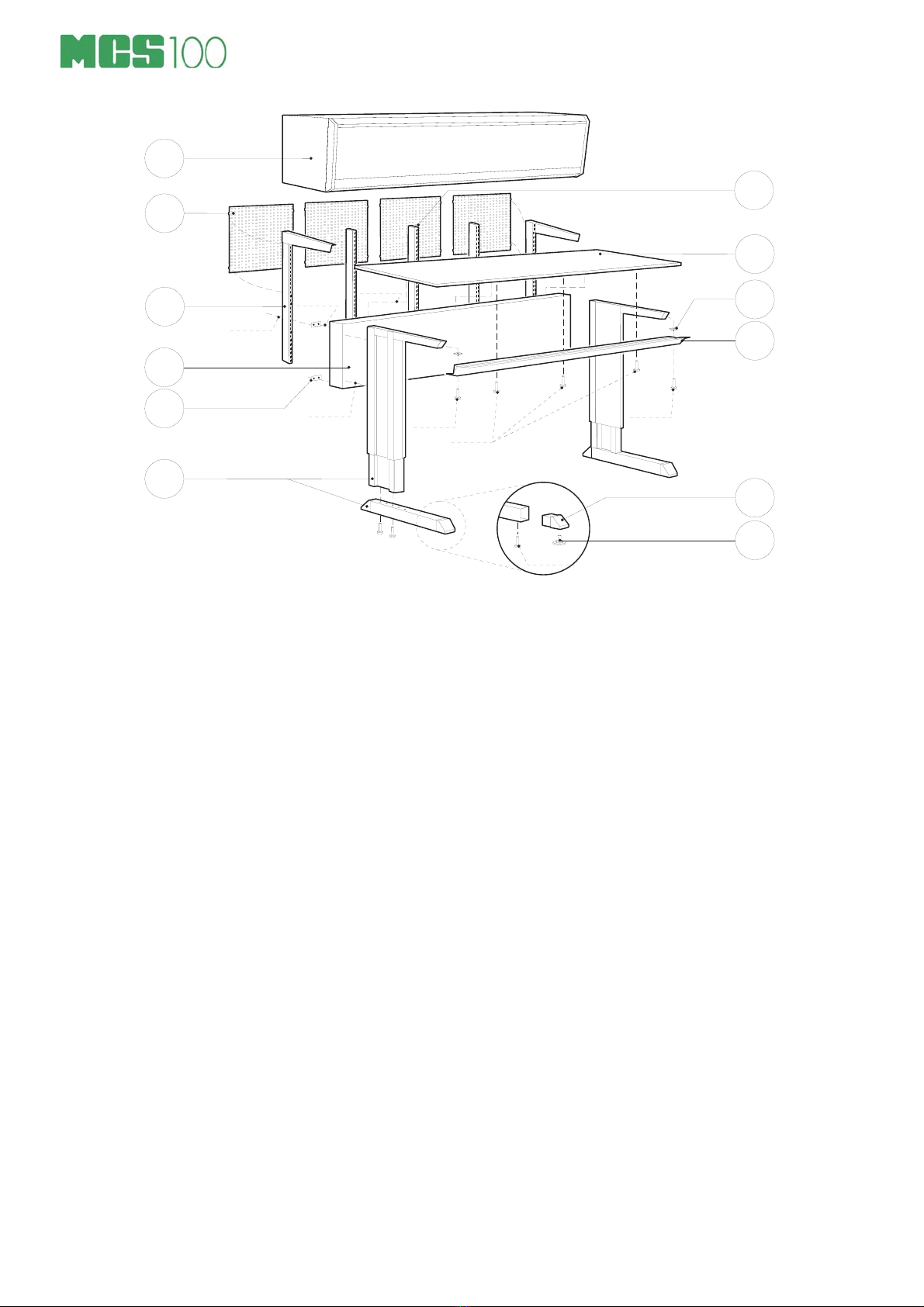

Assembly Instructions for High Workstations

Part List

Amount and part name

CODE

(if applicable)

Code in

the next

picture

1 Module rack with the modules installed A

3 Perforated plates 468 x 400 mm for a 1,5 m table or

3 Perforated plates 468 x 400 mm for a 1,8 m table or

4 Perforated plates 468 x 400 mm for a 2,0 m table

860800 B

2 Perforated plates 150 x 400 mm for a 1,8 m table 813486

1 pair of Brackets.

Inside each bracket are two M870 socket head

screws, M8 nuts and M8 washers. They are for

fastening the bracket.

For connecting the bracket to the bracket of another

table: two M612 crosshead screws, M6 nuts and

four M6 washers.

860288 C

1 Rear case, including the

Front list and the following utilities:

10 M816 socket head screws for fastening the

back case and the front list

6 M612 crosshead screws for fastening the

table top (not applicable for the corner unit)

6 M612 wood screws for alternate/additional

fastening of the table top

4 fitting parts with two M8 internal threads

each

2 flat nuts with an M8 internal thread

860019 D

J

E

I

1 Pair of legs, including the

leg caps and the

adjusting screws

860014 F

K

L

2 Perforated uprights for a 1,5 m table or

4 Perforated uprights for a 1,8 m table or

3 Perforated uprights for a 2,0 m table

Inside each perforated upright are two M870 socket

head screws and M8 nuts.

860142 G

1 Table top 860033 H

MCS100 User Guide 12

M × 1 6

D

E

M 6 ×1 2

M × 1 6 M × 1 6

L

J

H

G

M 6 × 1 2

A

B

CI

K

F

M × 7 0

M × 1 6

M × 1 6

1. Fix the adjusting screws Lto leg caps

K.

2. Fix the leg caps Kto the horizontal

part of the legs F. Fix the horizontal

part of the legs to the vertical parts (if

they are shipped separately).

3. Fix the rear case Dto the legs F,

smooth surface inside and with the

fixing holes for the table top up. Use

four M8×16 socket head screws.

4. Fix the flat nuts Ito the front list Jwith

M816 socket head screws (do not

tighten!). Push the front list Jin place

and tighten the screws.

5. Attach the fitting parts Eto the back

case Dwith four M816 socket head

screws (do not tighten!). Fix the

brackets C(2 pcs) with M870 socket

head screws to the rear case Dusing

the fitting part E(see picture on next

page).

6. Fix the perforated uprights G(the

amount of perforated uprights depends

on the width of your table, see picture

on next page) with M870 socket head

screws and M8 nut to the rear case E.

7. Fix the table top Hto the frame with six

M612 screws. If the table is equipped

with a drawer unit, the drawer fixing set

must be assembled before fixing the table

top. Note! The drawer unit includes it’s

own assembly instructions.

8. Install the isolation parts in the brackets

(see picture on next page).

9. Lift the module rack Aon to the brackets

Cand fasten it with the screws provided.

10.Fix the perforated plates Bto (the amount

of perforated plates depends on the width

of your table) to the perforated uprights

between the table top Hand the module

rack A.

Note that the frame of the table must

always be isolated from the module rack!

The height of the table top can be adjusted

between 670 to 1120 mm (approx. 26½” to

44”).

Max. loading capacity of the pair of brackets

Dis 120 kg (264 lbs).

MCS100 User Guide 13

Fixing the brackets to the rear case using

the fitting part:

Assembly instructions of the isolating

parts:

B r a c k e t

F i t t i n g

P a r t

M * 7 0

s o c k e t h e a d s c r e

w

W a s h e r , Ø 9

M * 1 6

s o c k e t h e a d s c r e w

R e a r C a s e

M 6 * 3 0

W a s h e r , Ø 7

( )

«

() Note! The isolating parts must

always be assembled as shown in

the picture.

The fixing points of the perforated uprights for the module rack and for the perforated

plates:

T a b l e T o p

2 m ´ 0 . 9 m

T a b l e T o p

1 . m ´ 0 . 9 m

T a b l e T o p

1 . 5 m ´ 0 . 9 m

5 0 c m 5 0 c m

5 0 c m4 0 c m5 0 c m5 0 c m5 0 c m 5 0 c m 4 0 c m 5 0 c m 5 0 c m

Corner Unit

The Corner Unit differs from a High

Workstation only by its special

look. Two High Workstations in a

90 degree angle may be combined

with the help of the Corner Unit.

MCS100 User Guide 14

How to Assemble the Corner Unit

We recommend that you first assemble the workstation(s) that will be

placed adjacent to the before assembling the corner unit.

1. Fix the front list Ato

the legs B. Use

M8×16 hexagon

socket head screws

and flat nuts.

2. Fix end plates Cto

the rear case D.

A

B

M × 1 6

Use M8×20 hexagon bolts and washers.

Note.

See the picture below for the purpose of each hole on the end

plate. Also remember to position the rear case so that the

fastening holes for the table top are on the upper side.

E

D

M × 1 6

2 × M × 2 0

P e r f o r a t e d U p r i g h t

R e a r C a s e

Leg

B r a k e t

C

3. Fix the rear case Dwith end plates to the legs E. Use M8×16

hexagon bolts and washers.

4. Fix the brackets Fto

the end plate Cusing

M8×70 hexagon

bolts, washers and

M8 nuts. Do not

tighten yet.

5. Fix the perforated

uprights Gto the end

plate Cusing M8×70

hexagon bolts,

washers and M8

nuts. Do not tighten

yet.

F

G

M

M × 7 0

Table of contents

Other BEAMEX Test Equipment manuals