TABLE

OF

CONTENTS

ECDECLARATION OF CONFORMlTY

......................................................................................................................

3

FOR UNITEDKINGDOM ONLY

....................................................................................................................................

4

1.FEATURES

AND

SAFETY TERMS

..............................................................................................................................

5

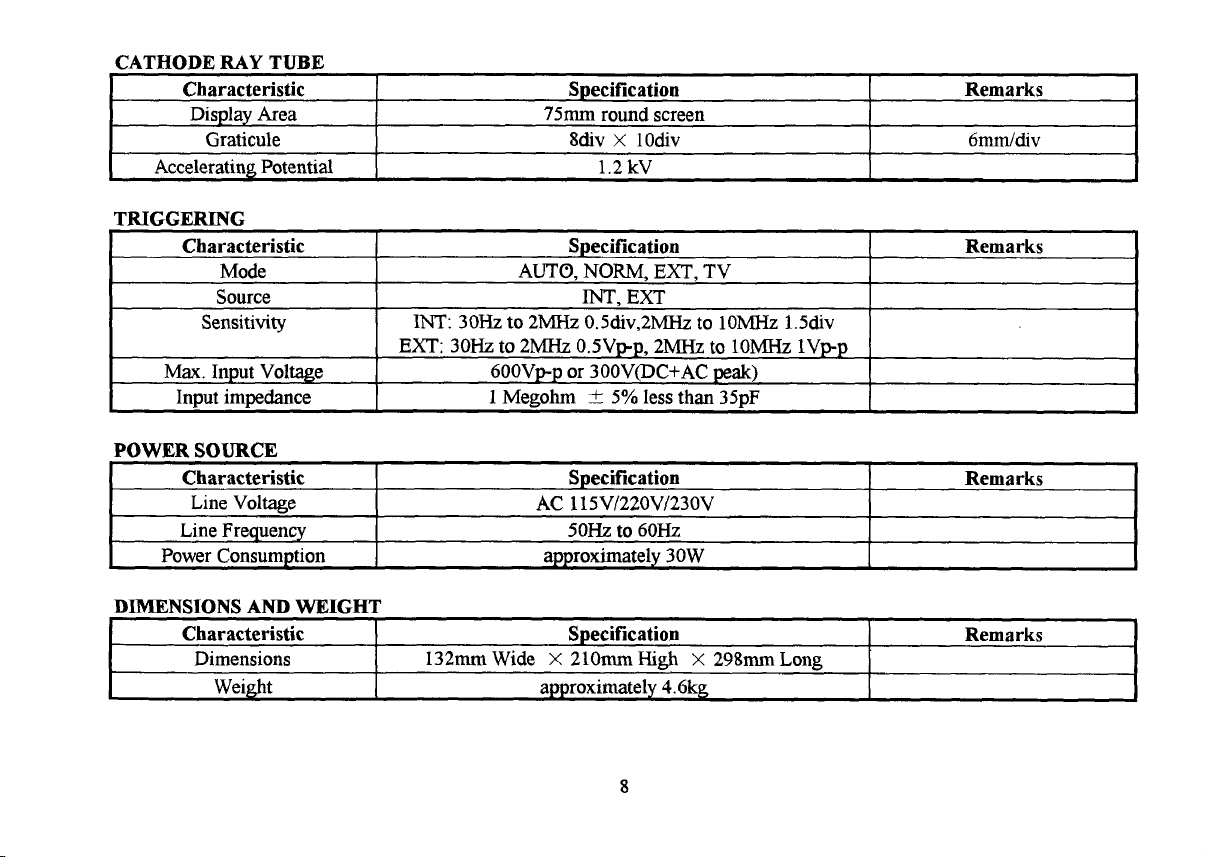

II.SPECIFICATI0NS

........................................................................................................................................................

7

III.PANEL CONTROLSAND FUNCl'IONS

..............................................................................................................

10

IV

.

GENERALEQUIPMENT SAFETY

.......................................................................................................

-

..............

12

V.SPEC1.LSAFETY NOTES ABOUT YOUR OSCILLOSCOPE

.............................................................................

12

M

.

PRECAUTIONS TOPROTECT YOUR OSCILLOSCOPE

...................................................................................

13

W

.

GENERAL OPERATION

........................................................................................................................................

14

1

.

INITIAL

SET.UP

........................................................................................................................................................

14

2

.

USING

DEFFREBT

TRIGGERINGMODES

....................................................................................................................

14

Vm

.

APPLICATIONS

.....................................................................................................................................................

16

1

.

DC VOLTAGE

MEAsUREMENT

..........................................................................................................................

16

2

.

PEAK-TO-PEAKVOLTAGE

-s

..........................................................................................................

17

3

.

PEAK-TO-PEAKVOLTAGEMEASUREMENTS

(OW

OF

RANGE)

....................................................................................

18

4

.

WAVEFORMPERIOD

-s

.....................................................................................................................

18

5

.

OW-OF-RANGE

PERIOD

-S

.................................................................................................................

20

6

.

PHASE

DIFFERENCE

(POINT-m

~OD)

......................................................................................

20

7

.

COMPARATIVE

FREQUENCY

-S

AND

PBASE

COMPARISONS

..................................................................

21

M

.

GENERALADJUSTMENTS

AND

CHECKS

........................................................................................................

24

1

.

PROBE

COMPENSATION

........................................................................................................................................

24

2

.

HORIZONTAL

TRACE

ALIGNMENT

wrr~

GRATICULE

..................................................................................................

24

3

.

QUICK CALIBRATIONCHECK

....................................................................................................................................

24

4

.

CASE

REMOVAL

.......................................................................................................................................................

25

5

.

FUSE

REPLACEMENT

................................................................................................................................................

25

6

.

CHANGINGVOLTAGE

OF

OPERATION

........................................................................................................................

26

7

.

POWER

SUPPLY

VOLTAGECHECKS

...........................................................................................................................

26

8

.

A~~IGMATISM

AD-

.....................................................................................................................................

27

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com