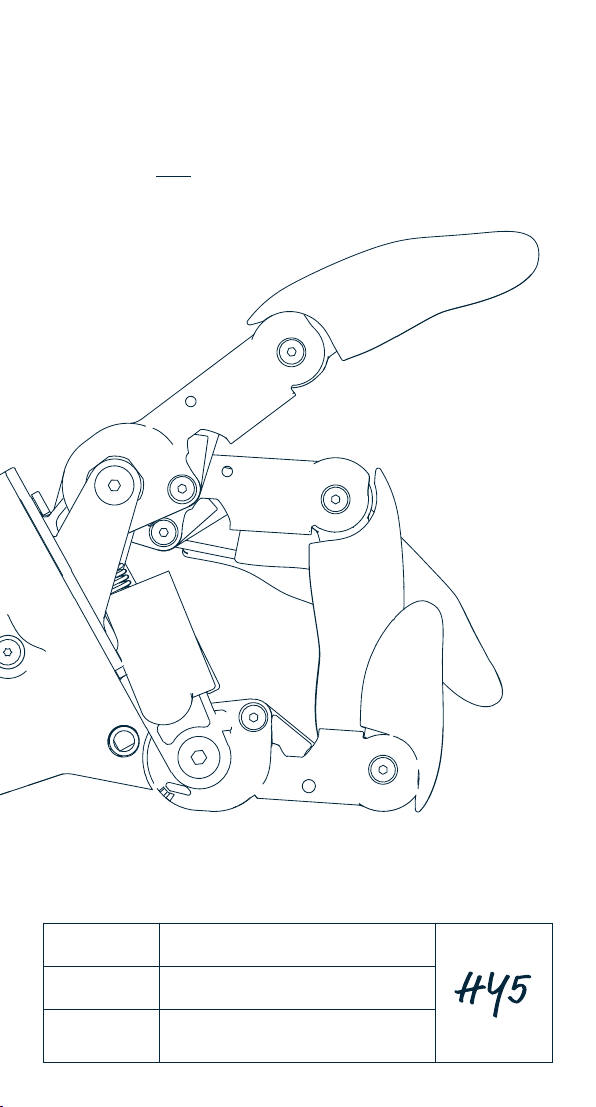

1.2 MYHAND SERVICE CHECK LIST 2. HY5 PROSTHESIS & THIRD PARTY

COMPONENTS

The third party components that the Hy5 hand needs in order

to work includes;

• Socket

• 5A battery

• 2 myo sensors.

Hy5 is connected to the socket with the quick disconnect. A Hy5

prosthesis glove size 7 ¾ shall be used on the hand at all time.

A complete User Manual is delivered with Hy5.

CAUTION!

CAUTION!

2.1 Electrodes/Myo sensors

Hy5 needs 2 myo sensors to operate.

When the Hy5 hand is connected to the socket, the user shall

operate the hand for a few minutes to clarify whether the myo

sensors need sensitivity adjustments. The feedback from the

user allow for optimizing the myosensors to the users’ personal

preferences.

When the sensors are optimized to the user, the user shall be giv-

en some more minutes to operate and get familiar with the new

hand. Hy5 is ready for use.

The battery is located inside the socket, and is not delivered by

Hy5Pro AS.

2.2 Batteries

Only a 5A battery should be used with

MyHand. Use of other battery systems will

result in poor performance of MyHand.

The following checks can be made to identify if the hand needs to

be returned to Hy5Pro AS for maintenance:

1. Check the hand turns on/off reliably.

2. Check hand closing time < 1,5s.

How: Use video camera to time several closing sequences,

from fully open to point of rst contact

3. Check hand switches to high power mode

How: Use battery pack to perform pinch grip around your

open hand. If the pinch force becomes uncomfortable, this is

a clear indication that high power mode is functional. Stop

gripping before the hand exhibits excessive force

4. Check for any signs of oil leaks

How: Examine closely for oil in the following locations:

— Around oil-lling screws

— Around edge of mounting frame

— Around emergency release switch

— Around edge of quick disconnect

— Around cylinder rods

5. Check for any visible signs of damage

How: Check all around the hand for any signs of broken or

deformed components

6. Check ngers move freely

How: Rotate each nger joint individually. Each joint should

spring back under spring-force, and there should be no rub-

bing or grinding in the joint

7. Check emergency valve functions as intended – both open

and close

How: Close hand using battery pack. Open emergency re-

lease switch – ngers should open. Close emergency release

switch, and close hand again.

8. Check quick disconnect connects/disconnects in a reliable

manner

How: Use battery pack to check reliable connect/disconnect.

Hand should not switch off when quick connect is rotated and

hand is on

If the hand fails on any of these points, it should be returned for

maintenance.