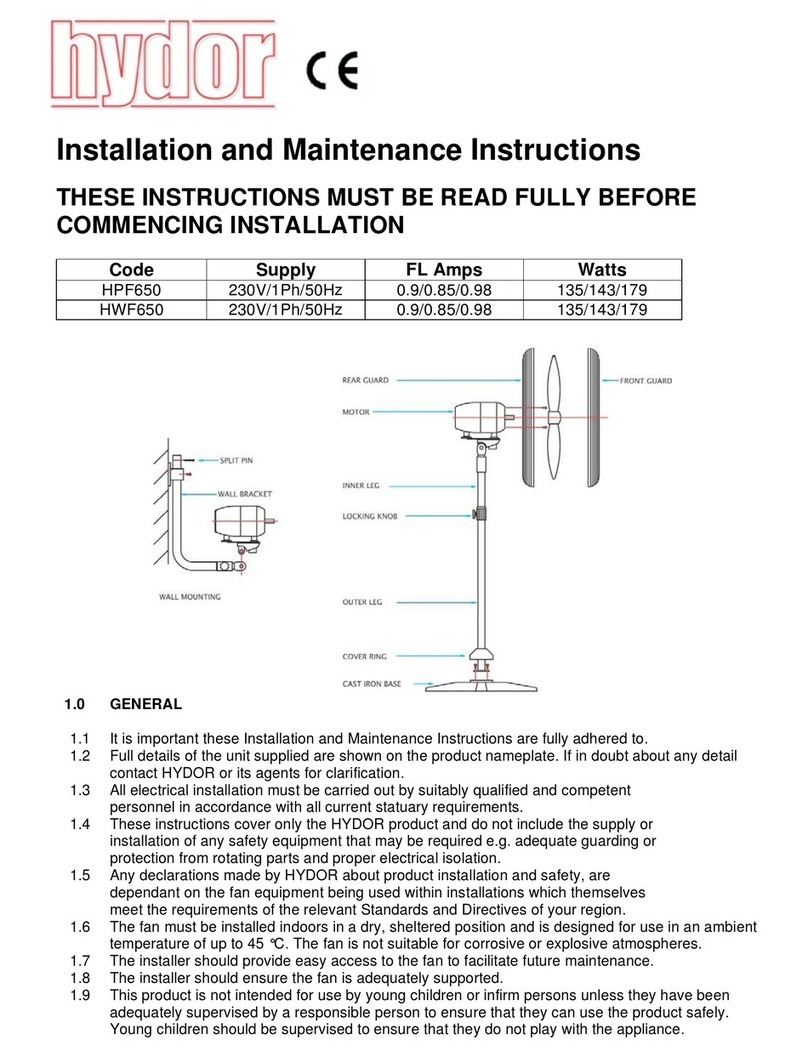

2. Installation

2.1 Upon receipt, the fan unit should be visually inspected to check for any

damage. Ensure that the impeller is free to rotate.

2.2 If there are any queries concerning the fan unit, Hydor should be

contacted prior to installation.

2.3 The fan unit should be securely mounted in the required position to suit

the application.

2.4 Check the details on the motor rating plate to ensure that the correct

power supply [voltage, frequency and phase] and starters are available.

Particularly if the motors are to be controlled by an inverter speed control.

An incorrect power supply will lead to permanent damage to the motor.

2.5 Means for electrical disconnection must be incorporated in the installation

in accordance with the relevant the wiring and electrical regulations.

Ensure that all earth connections are made and secure.

2.6 If the fan is being used through a speed control device, either electrically

or electronically, refer to the relevant control device instructions. Before

commencing installation.

3. Operation

3.1 Before power is supplied to the unit, check that the wiring is correct as per

the fan connection diagram and control instructions [If tted].

3.2 At initial start-up, check that the impeller rotation and airow direction is

correct.

3.3 Check that the motor amperage drawn does not exceed the nameplate

rating at full speed.

4. Fan Maintenance

4.1 Inspection of the fan unit at least every 6 months is recommended to

ensure that the motor and fan blades are clean. Any build-up of dust

deposits should be removed using a non-abrasive cleaner.

4.2 All fastenings should be checked for tightness. In addition, all rotating

items should be checked.

4.3 Bearings are of the “sealed for life” variety and will not need a detail

inspection.

WARNING:Onlyasuitablyqualiedandcompetentpersonmaycarry

out maintenance after the electrical supply has been isolated. Particular

care must be taken when automatic switching controls are used.