1. General

1.1 It is important these Installation and Maintenance Instructions are fully

adhered to.

1.2 Full details of the unit supplied are shown on the product nameplate. If in

doubt about any detail contact Hydor or its agents for clarication.

1.3 All electrical installation must be carried out by suitably qualied and

competent personnel in accordance with all current statutory

requirements.

1.4 These instructions cover only the Hydor product and do not include

the supply or installation of any safety equipment that may be required

e.g. adequate guarding or protection from rotating parts and proper

electrical isolation.

1.5 Any declarations made by Hydor about product installation and safety,

are dependent on the fan equipment being used within installations which

themselves meet the requirements of the relevant Standards and

Directives of your region.

1.6 The fan is designed for use in an ambient temperature of -20°C up to a

maximum of +70°C, speed controlled operating

temperatures of -20°C and +50°C and up to 95% relative humidity. EC fans

are designed for ambient temperatures up to +60°C. The fan is not

suitable for corrosive or explosive atmospheres.

1.7 The installer should provide easy access to the fan to facilitate future

maintenance.

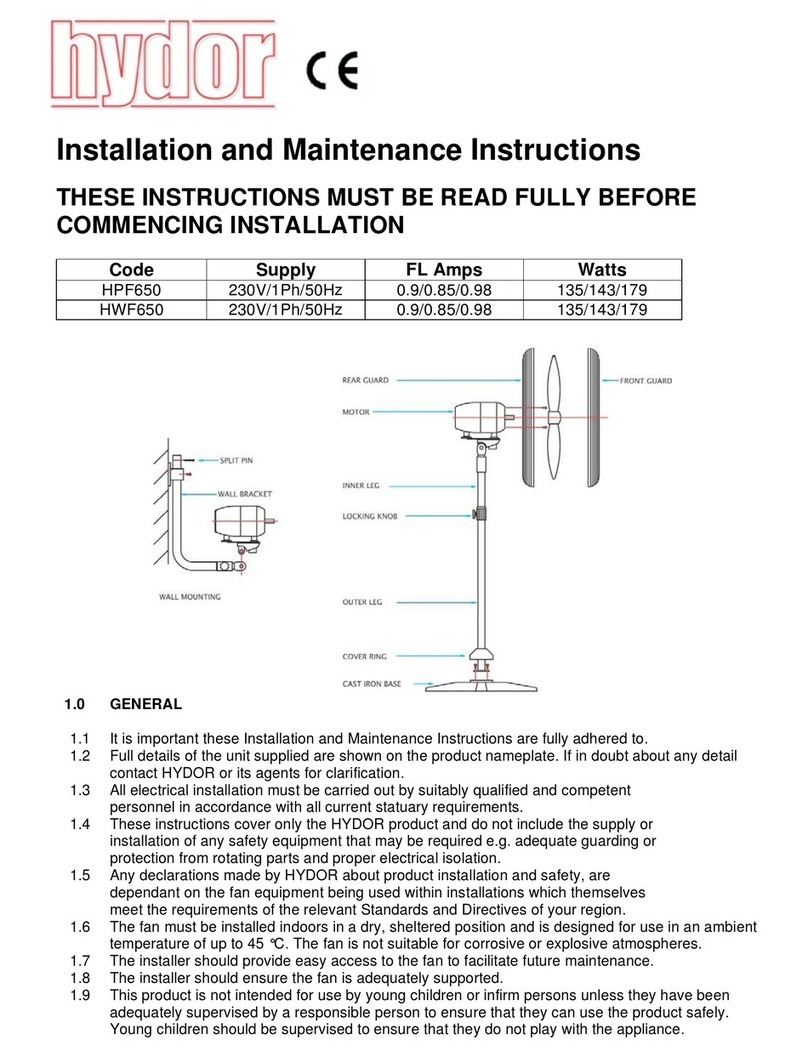

1.8 The installer should ensure the fan is adequately supported.

1.9 This product is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction

concerning use of the product by a person responsible for their safety.

Children should be supervised to ensure that they do not play with

the product.

1.10 At end-of-life, the unit must be disposed of in an environmentally friendly

manner by suitably qualied and competent personnel in accordance with

the requirements of applicable Standards and Directives.

2. Installation

WARNING: The fan must be isolated from the power supply during

installation and maintenance. The fan must be earthed in accordance

with the local regulations.

2.1 Upon receipt, the fan equipment should be visually inspected to check for

any damage. Ensure that the impeller is free to rotate.

2.2 If there are any queries concerning the fan equipment, Hydor should be

contacted prior to the installation.

2.3 The fan must be securely mounted in the desired position to suit the