1.6 The fan is designed for use in an ambient temperature of up to 70°C (fixed

speed), 55°C (speed controlled) and up to 95% relative humidity. The fan is

not suitable for corrosive or explosive atmospheres.

1.7 The installer should provide easy access to the fan to facilitate future

maintenance.

1.8 The installer should ensure the fan is adequately supported.

1.9 This product is not intended for use by young children or infirm persons

unless they have been adequately supervised by a responsible person to

ensure that they can use the product safely. Young children should be

supervised to ensure that they do not play with the appliance.

WARNING The fan must be isolated from the power supply during

installation and maintenance. The fan must be earthed in accordance

with the local regulations.

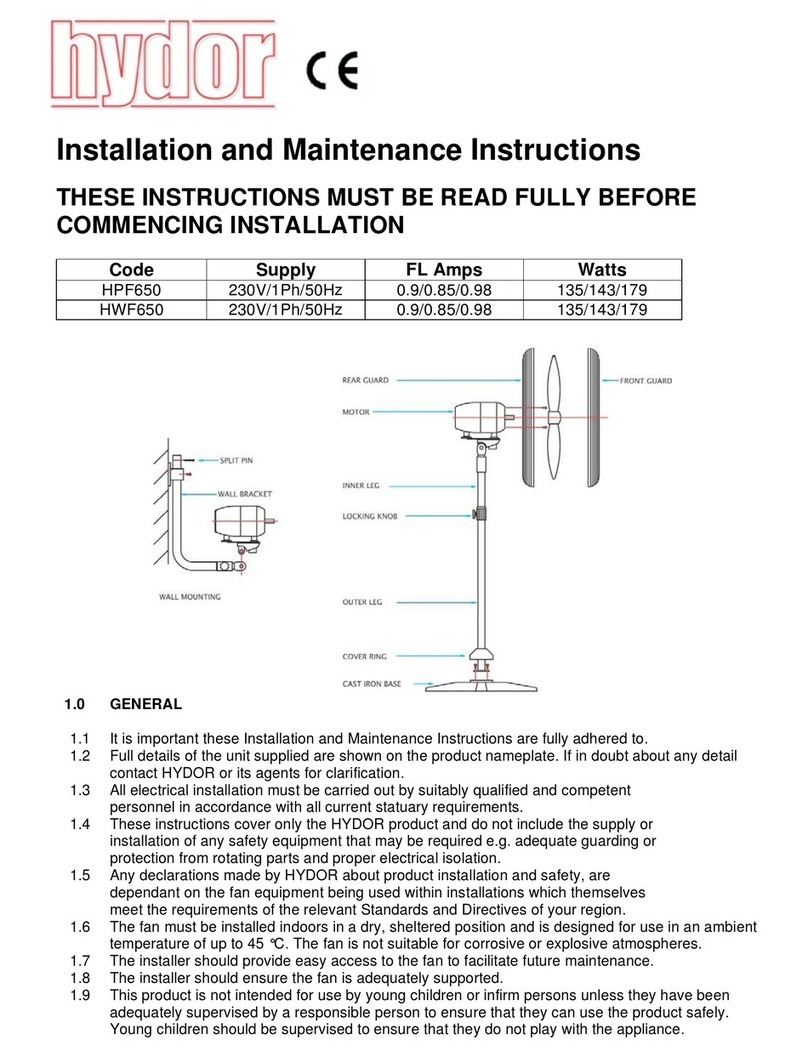

2. Installation

2.1 The HXP range of fans is normally supplied assembled. The single phase

units are supplied with the Capacitor loose.

2.2 Upon receipt, the fan equipment should be visually inspected to check for

any damage. Ensure that the impeller is free to rotate.

2.3 If there are any queries concerning the fan equipment, Hydor should be

contacted prior to the installation.

2.4 The fan must be securely mounted in the desired position to suit the

application. The fan can be mounted at any angle.

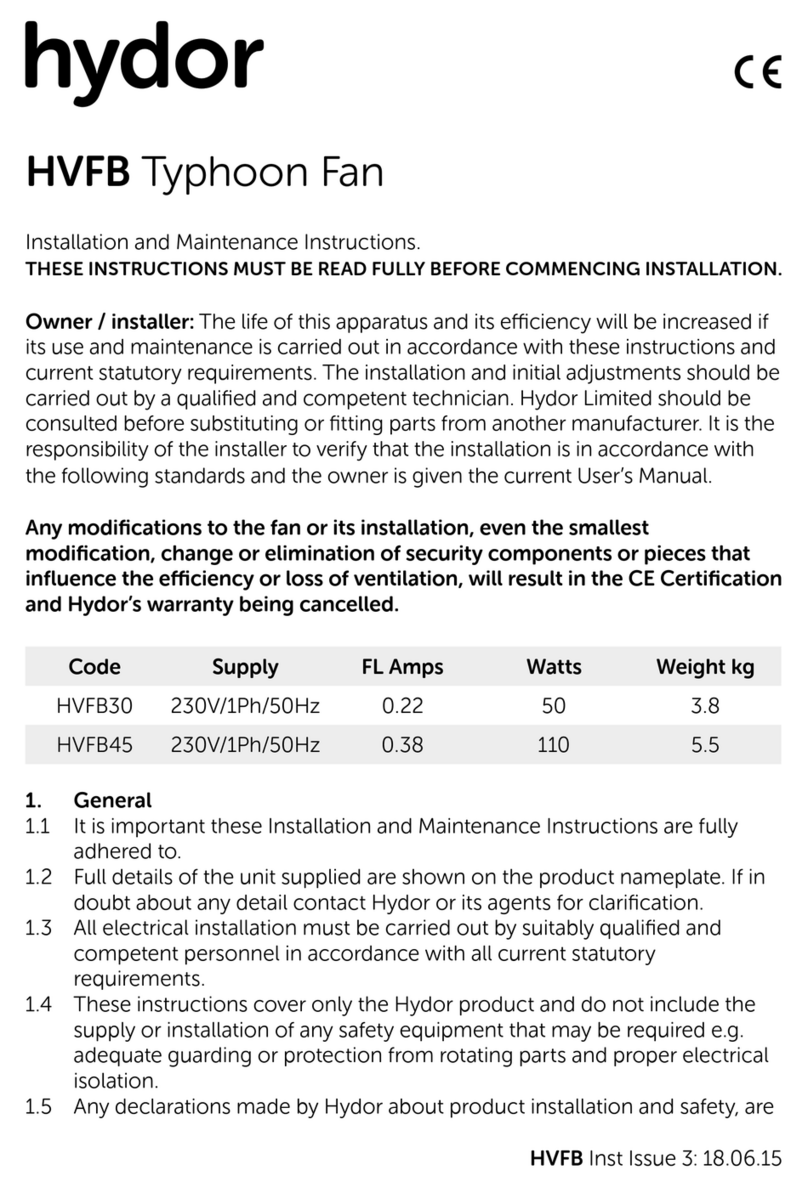

2.5 Check the details on the motor rating plate to ensure that the correct

power supply (voltage, frequency and phase) is available. An incorrect

power supply will lead to permanent damage to the fan motor.

2.6 Refer to the appropriate wiring diagram. Ensure that all earth connections

are made.

2.7 Means for electrical disconnection must be incorporated in the wiring

installation in accordance with the relevant wiring and electrical

regulations.

2.8 Precaution must be taken to locate the exhaust discharge terminal so as to

avoid the backflow of gases into the room from the open flue of gas or

other fuel burning appliances.

2.9 If the fan is being used through a speed regulation device, either

electrically or electronically. Please refer to the relevant control device

instructions.

3. Start-up

3.1 Before power is supplied to the unit, check that the wiring is correct as per

the fan connection diagram.