HPA Inst Issue 2: 01.22

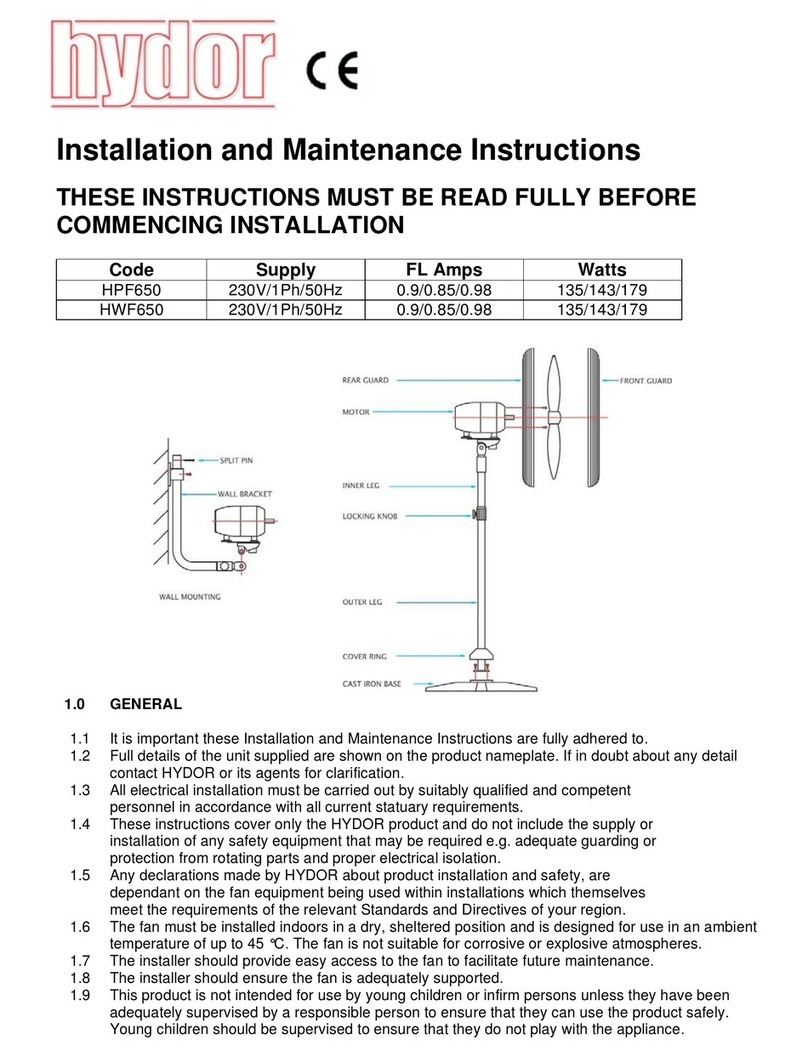

1.8 The installer should ensure the fan is adequately supported.

1.9 This product is not intended for use by young children or inrm persons

unless they have been adequately supervised by a responsible person to

ensure that they can use the product safely. Young children should be

supervised to ensure that they do not play with the appliance.

WARNING The fan must be isolated from the power supply during

installation and maintenance. The fan must be earthed in accordance

with the local regulations.

2. Installation

2.1 Upon receipt, the fan equipment should be visually inspected to check for

any damage. Ensure that the impeller is free to rotate.

2.2 If there are any queries concerning the fan equipment, Hydor should be

contacted prior to the installation.

2.3 The fan must be securely mounted in the desired position to suit the

application.

The fan can be mounted at any angle.

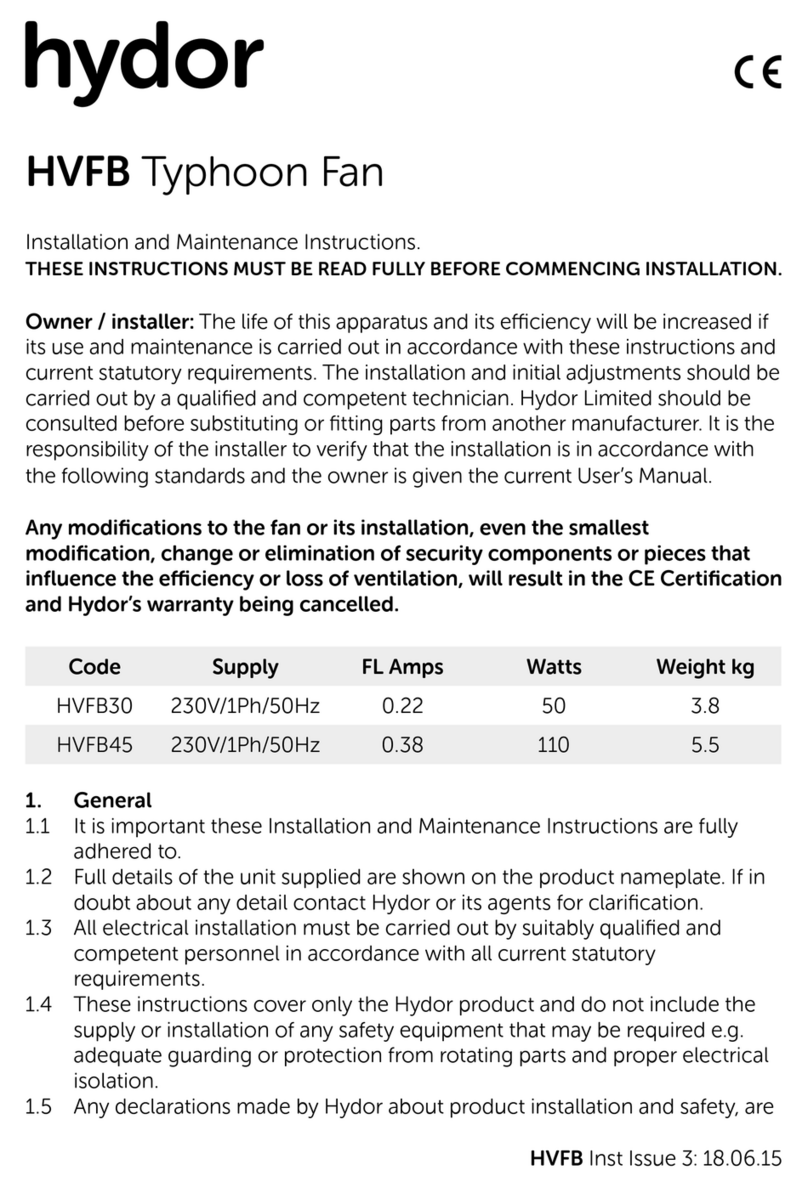

2.4 Check the details on the motor rating plate to ensure that the correct

power supply (voltage, frequency and phase) is available.

An incorrect power supply will lead to permanent damage to the fan

motor.

2.5 Refer to the appropriate wiring diagram. Ensure that all earth connections

are made.

2.6 Means for electrical disconnection must be incorporated in the wiring

installation in accordance with the relevant wiring and electrical

regulations.

2.7 Precaution must be taken to locate the exhaust discharge terminal so as to

avoid the backow of gases into the room from the open ue of gas or

other fuel burning appliances.

3. Start-up

3.1 Before power is supplied to the unit, check that the wiring is correct as per

the fan connection diagram.

3.2 At initial start-up, check that impeller rotation and airow direction is

correct.

3.3 Check that the motor amperage draw does not exceed the nameplate

rating.

4. Fan Maintenance

4.1 Inspection of the fan at least once every 12 months is recommended to

ensure that the motor, fan blades, and supporting guards, are clean. Any

build up of dust and deposits on the blades or guards should be removed

using a non-abrasive cleaner.

4.2 All fastenings should be checked for tightness. In addition, all rotating