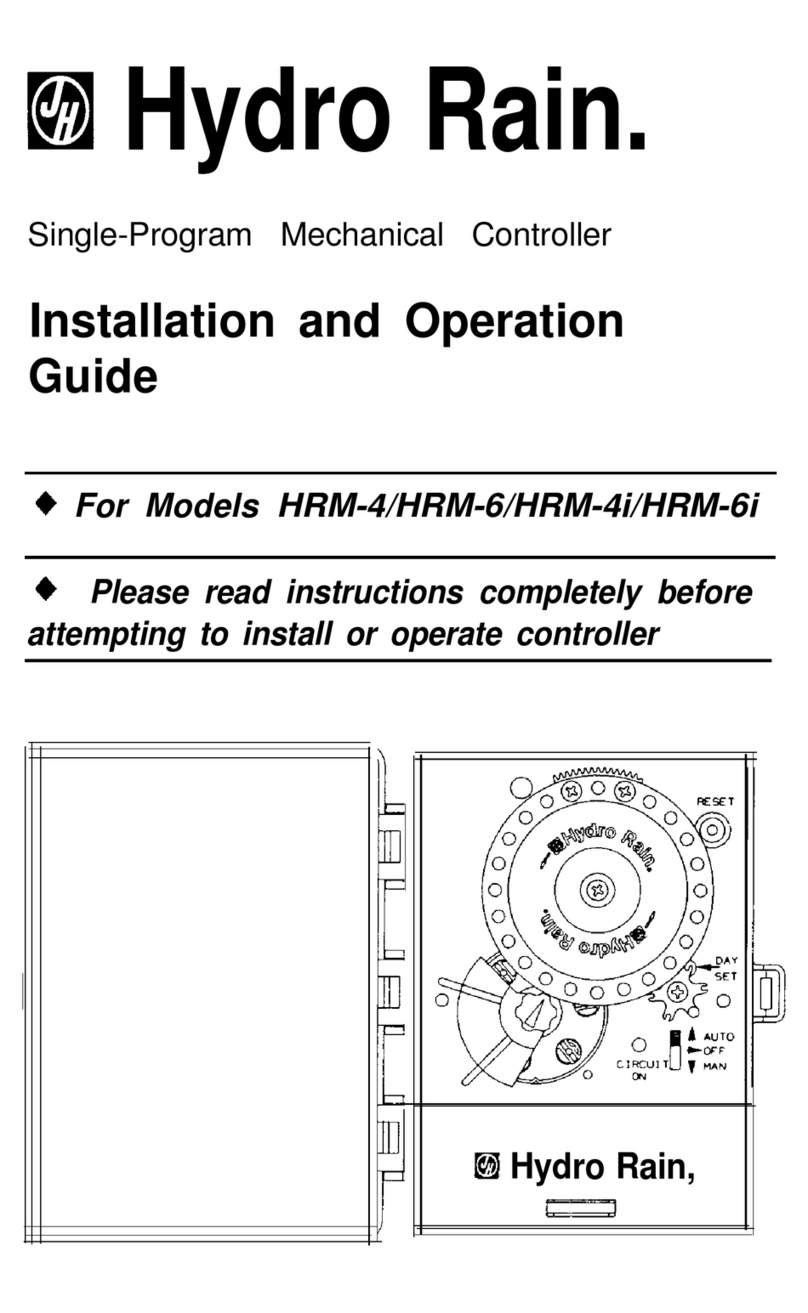

The HRM-12 is a 12 station controller that can be set to water from twenty-four

times a day to once every two weeks. The watering time can be adjusted from

approximately 5 to 60 minutes for each circuit. The controller is in a weather

resistant case that can be mounted on a two

inch

pipe pedestal or against a wall

with wood screws. The controller has a lockable cover, with two keys, to

discourage unauthorized adjustment.

STEP 1: WALL MOUNTING

Open the cover of the controller and open the panel by unscrewing the latch

screw. (See Figure 3). Disconnect the wiring connector and rotate the panel until

it can be lifted up off the hinges. Punch through the three mounting holes so No.

8

wood screws can pass through the back of the case. Place the empty controller

box against the wall and screw three No. 8 wood screws through the back and

into the wall.NOTE: To install the timer on a plaster or masonry wall, use plastic or

lead shields to secure screws.

STEP 2: CONNECT THE TRANSFORMER

This connection should be made by a licensed electrical contractor in

accordance with all requirements of the National Electrical Code and

applicable state and local codes.

Using the

7/8

inch conduit hole in the bottom of the cabinet, run the 120V AC

power wires into the wiring cavity. Remove the Caution High Voltage plate and

use wire nuts to connect the white wire as the common, the black wire as the

power, and the green wire as earth ground.

CAUTION: Make sure the 120V circuit breaker is turned to the off

position prior to wiring the controller.

After the electrical wires are attached, replace the caution plate before turning

the circuit breaker on.

STEP 3: CONNECT THE VALVE WIRES

Run the valve wires through the 2 inch hole and connect them to the terminal

strip inside the controller. Connect the wire from valve No. 1 to the terminal

marked No.

1,

valve No. 2 to terminal 2, etc. (See Figure 2). Connect the valve

common wires to any terminal marked C. If the valve wires are to be run through

conduit, a conduit junction box can be used by placing a reducer from 2 inch on

one end and screw the 2 inch reducer into the hole.

STEP 1: PEDESTAL MOUNTING

The pedestal should be mounted on a level concrete base about lOxlOx8

inches with the top of the concrete base at least two inches above ground

level. Position a 2 inch elbow and a

1/2

inch conduit in the concrete form as

shown. The elbow and conduit must be in position before the concrete is

poured. Four hold down bolts must be positioned in the concrete before it

sets. Feed the

12OV

AC power wires through the conduit. Screw the 2 inch

pedestal pipe into the controller and run the ring nut up tight against the

controller to lock its position on the pedestal. Do not use pipe dope as a

sealing compound.

Lower the controller, with pedestal attached down upon the concrete

base, at the same time feeding the conduit with power wires inside into the

controller’s conduit opening. Secure the conduit to the controller and

tighten pedestal base nuts.

STEP2: CONNECT THE TRANSFORMER

Open the cover of the controller and

loosen the latch screw (See Figure 3) to

swing out the control panel. Remove the

Caution High Voltage plate and use wire

nuts to connect the white wire as the

common, the black wire as the power, and

the green wire as earth ground.

CAUTION: Make sure the

120V circuit

breaker is turned to the off position prior

to wiring the controller.

FIGURE 1

After the electrical wires are attached,

replace the caution plate before turning the

circuit breaker on.

STEP 3: CONNECT THE VALVE WIRES

Run the valve wires through the 2 inch

pedestal pipe and connect them to the

terminal strip inside the controller. Connect

the wire from valve No. 1 to the terminal

marked No.

1,

valve No. 2 to terminal No. 2,

etc. Connect the valve common wires to any

terminal marked C. (See Figure 2).

2

3