Hylio Agrodrone (AG-110) Maintenance Manual

©2020 Hylio Inc. All Rights Reserved 9

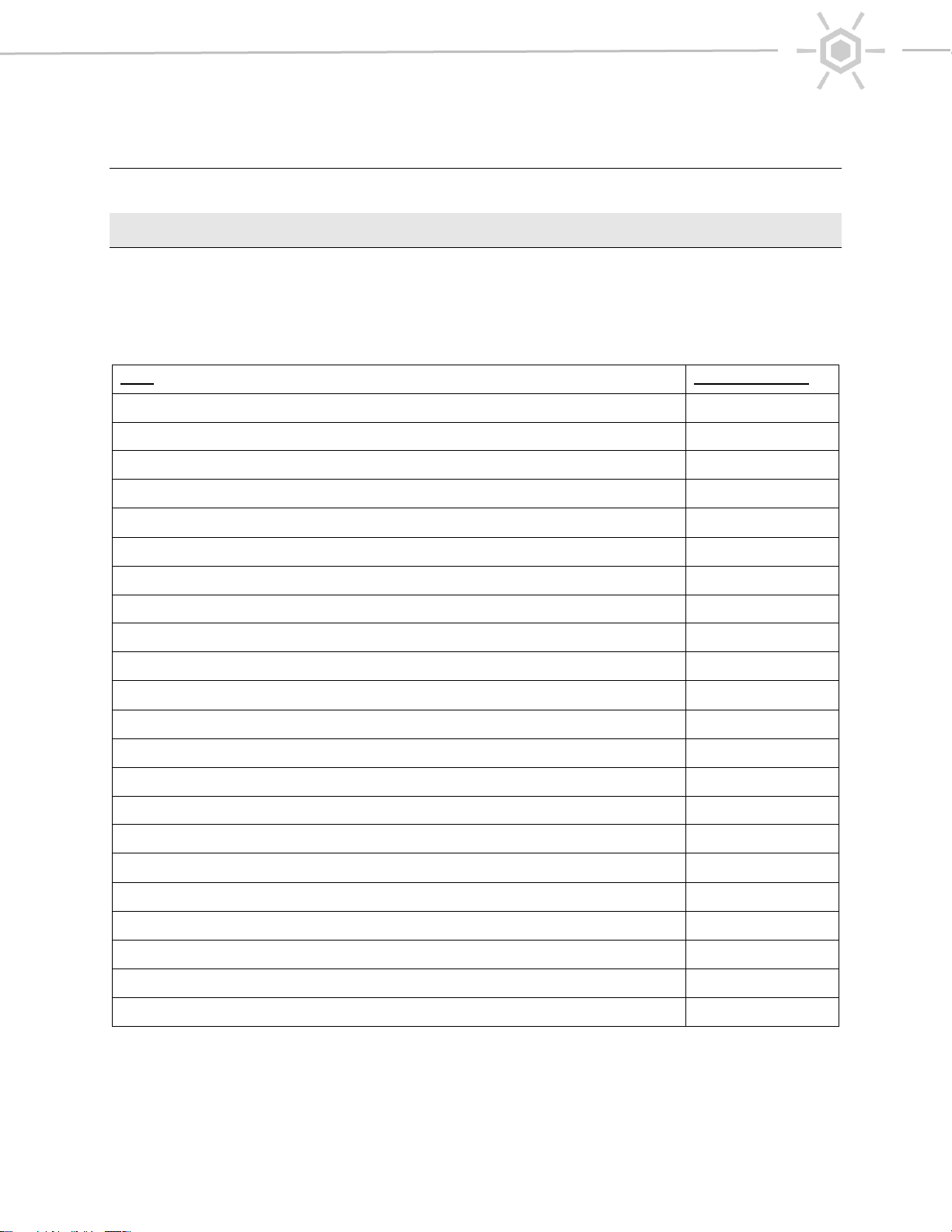

Flight Testing

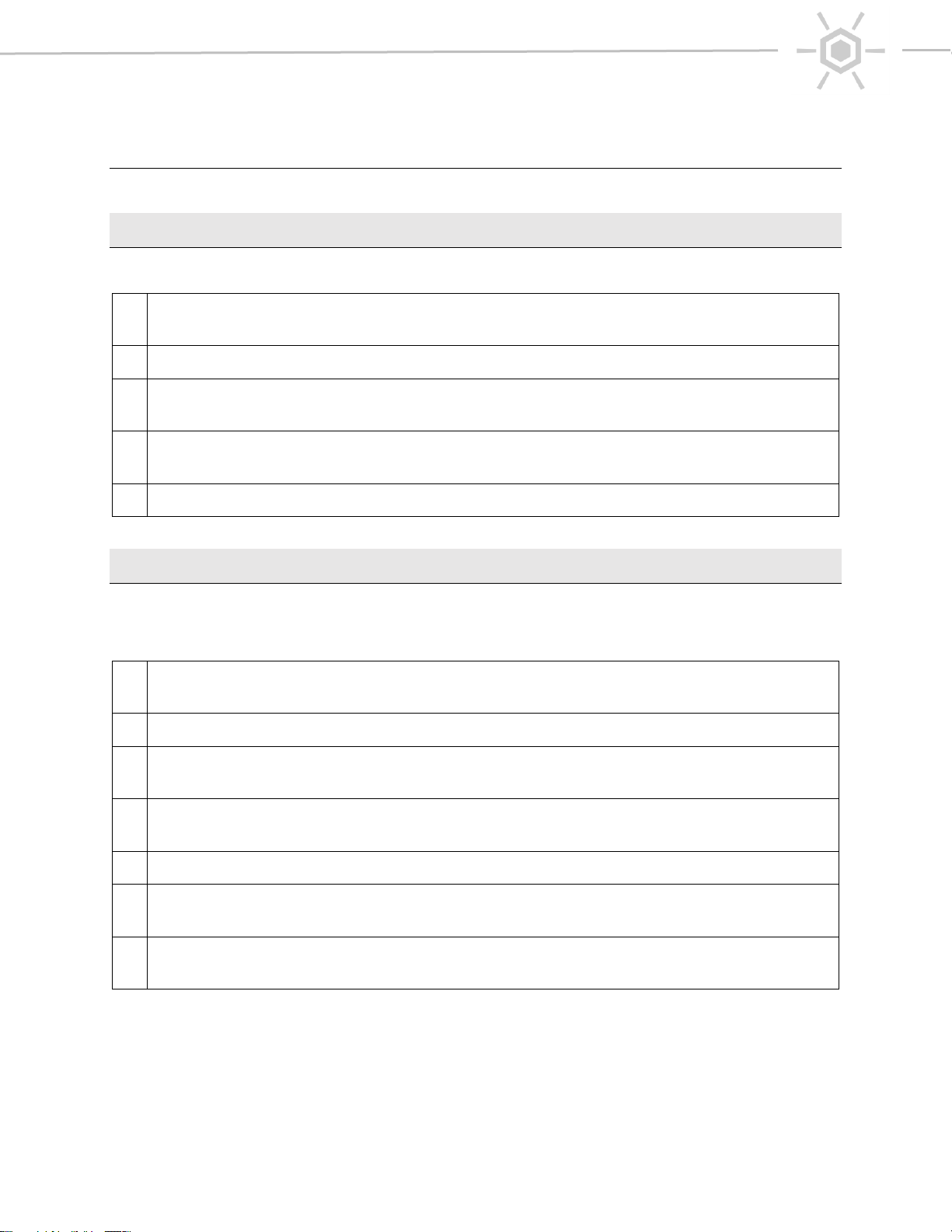

When to Flight Test

Follow ground testing checklist after any of the following events:

- Crash

- Unknown issue stops user from flying

- At every 10-hour routine maintenance check

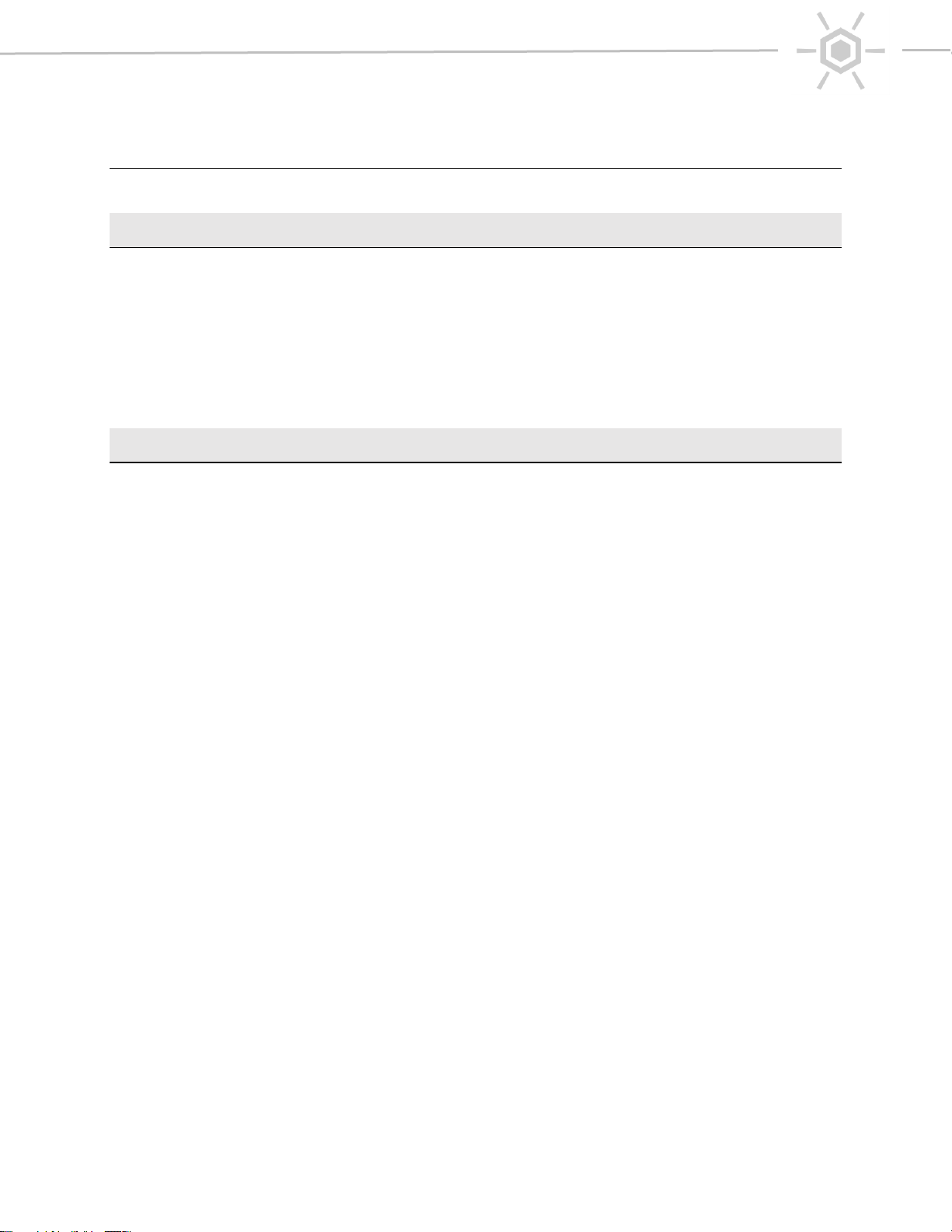

Flight Test Steps and Checks

1) Take drone outside to a safe and open testing field

2) Perform accelerometer, compass and level calibrations. Check that all calibrations are

able to be completed

3) Upload a safe standard testing mission. This mission should be verified safe and low

altitude by flights on another drone that is confirmed to fly well. This mission should be

no more than an acre. Ensure the RTL altitude and spray altitude are separated by at

least 10 ft. Upload mission with 0 pump power. Check that the mission uploads on the

first try. Check that the mission appears in the operations tab as uploaded

4) STRICTLY FOLLOW PREFLIGHT CHECKLIST

5) Arm motors. Check that all 6 motors spin up in the right CW/CCW direction

6) Take off. Check that drone takes off to correct RTL altitude. Check the motors are not

making any unusual noises. Check the drone appears to fly stable

7) As the drone descends to the mission area, check that it yaws to face the mission line

direction within acceptable error, (recalibrate compass if not)

8) Check that the drone flies stable during the spray section of the mission, check the

drone reaches speeds as set on the spray mission.

9) Pause drone. Check that pause and click to fly work. Resume mission. Check that

resume mission works. RTL mission. Check that RTL works

10)When the drone returns to descend for land, check that the land looks stable and

controlled.

11)Fill the tank with 2 gallons of fluid. Upload a mission using dynamic flowrate that will

spray 1.5 gallons over the entire mission. Follow steps 4-7 again.

12)Let the drone finish the mission, and measure the remaining volume in the tank.

Recalibrate flowmeter if off by more than 5%

13)Perform one final flight with a full tank. Adjust the mission dynamic flowrate to spray the

full tank over the mission area AND RUN EMPTY. Turn on empty tank RTL. Use the

Toolbox calculator to ensure a slow enough speed is selected. Follow steps 4-7 again.

14)Verify the drone RTL when the tank is empty. Verify the total volume sprayed in AgroSol

matches what was sprayed.