2/7

4986-(EN) BETJENINGSVEJLEDNING A16-77 A10 2018-12-17 R1 S12018-12-17 R1 S1

Thank you for choosing a Compac product.

Warranty:

A 3-year warranty is furnished with the product,

provided that the product is handled in accordance with

the directions below. Please see page 7 for complete

warranty information.

Note: Do not undertake constructive changes.

Cautions - safety measures

1. The jack must only be used by trained personnel who

have read and understood this manual.

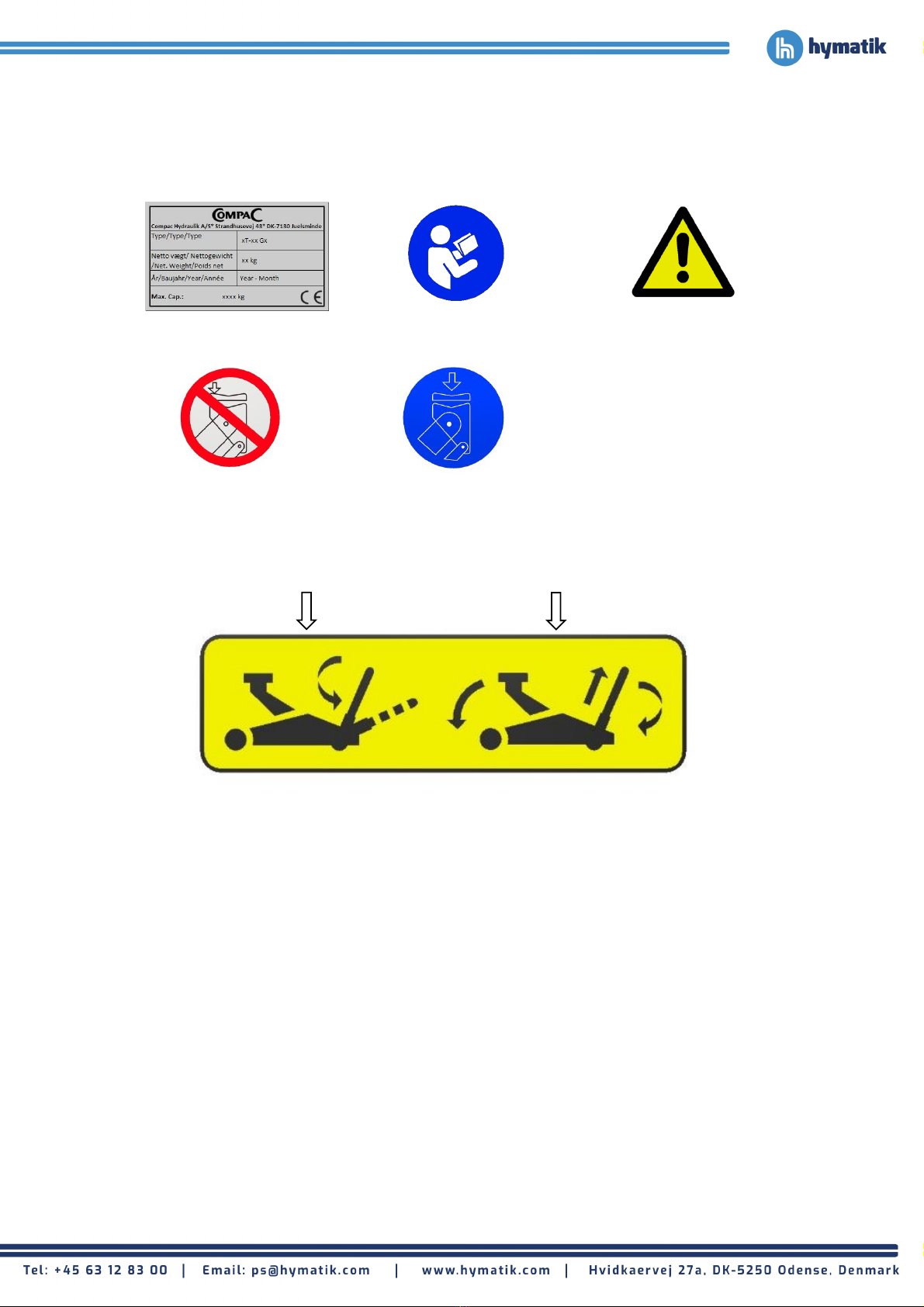

2. Avoid overloading. The capacity must not be exceeded.

3. The jack must only be used on a horizontal, level and

structurally stable substrate.

4. The vehicle's wheels must be pointed forward and

braked or blocked.

5. The jack is solely a lifting tool. Always support the vehicle

with approved jack stands before working underneath the

vehicle.

6. Lift only at the vehicle's lifting points as prescribed by the

manufacturer, and only centrally on the saddle.

7. Being in, on or under a vehicle that is lifted or solely

supported by a jack is forbidden.

8. The jack may be used with a maximum of 1 standard

extension piece.

9. The jack - including the pressure relief valve - must not

be modified.

10. Maximum allowable air pressure: 10 bar/145 psi,

minimum 300l/min.

11. Min. distance to walls min. 0.5m wrt/ emergency

escape routes.

12. Lacking compliance with these warnings can cause the

load to fall down or the jack to malfunction, which may

result in personal injuries or material damage.

The jack must only be used from -5° to + 40°

Mounting: See page 3

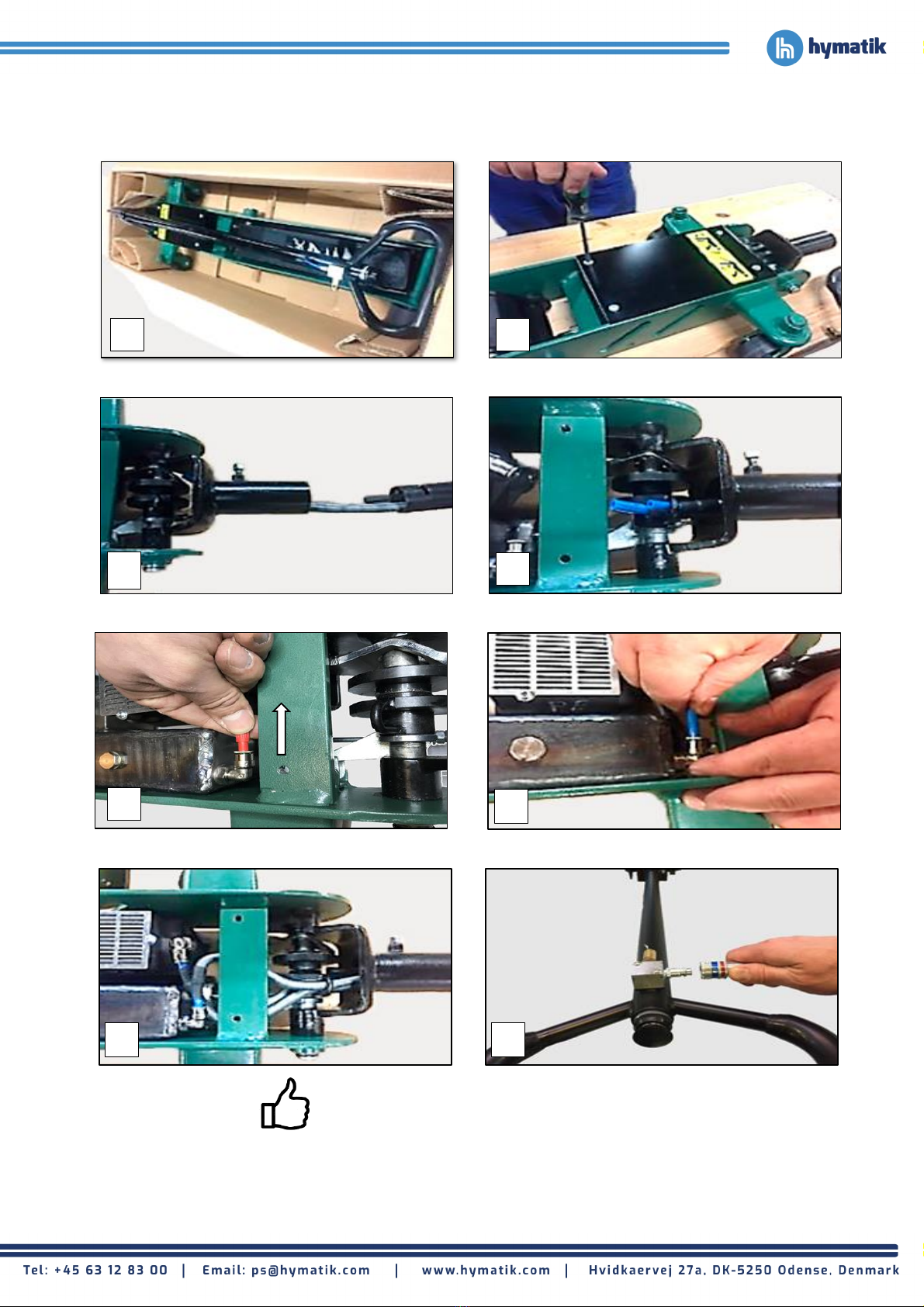

For mounting of joystick, see picture (1-7).

IMPORTANT: The hoses must go through the eye at the pull

handle head, large hose at the bottom and small hose at

the top (see picture 4). Remove the red plug (see picture 5).

CAUTION:

Before placement into service and subsequently at periodic

intervals, lubricate all movable parts with oil. Air

connection: 1/8”RG (see picture 7). Full capacity is achieved

from 8 bar. Maximum air pressure :10 bar/145 psi.

Operating manual:

Transport and store the jack standing on its wheels.

Raising: Press on the operating valve at the top of the

handle (see picture 11), the pump will start, and the jack

will rise.

Lowering: Pull the handle up and turn it clockwise (see

picture 12.13).

The handle can be set in 3 different positions (see picture

8-10) by turning the handle clockwise and tilting it up or

down to the desired position.

Maintenance:

Maintenance and repairs must be performed by qualified

personnel.

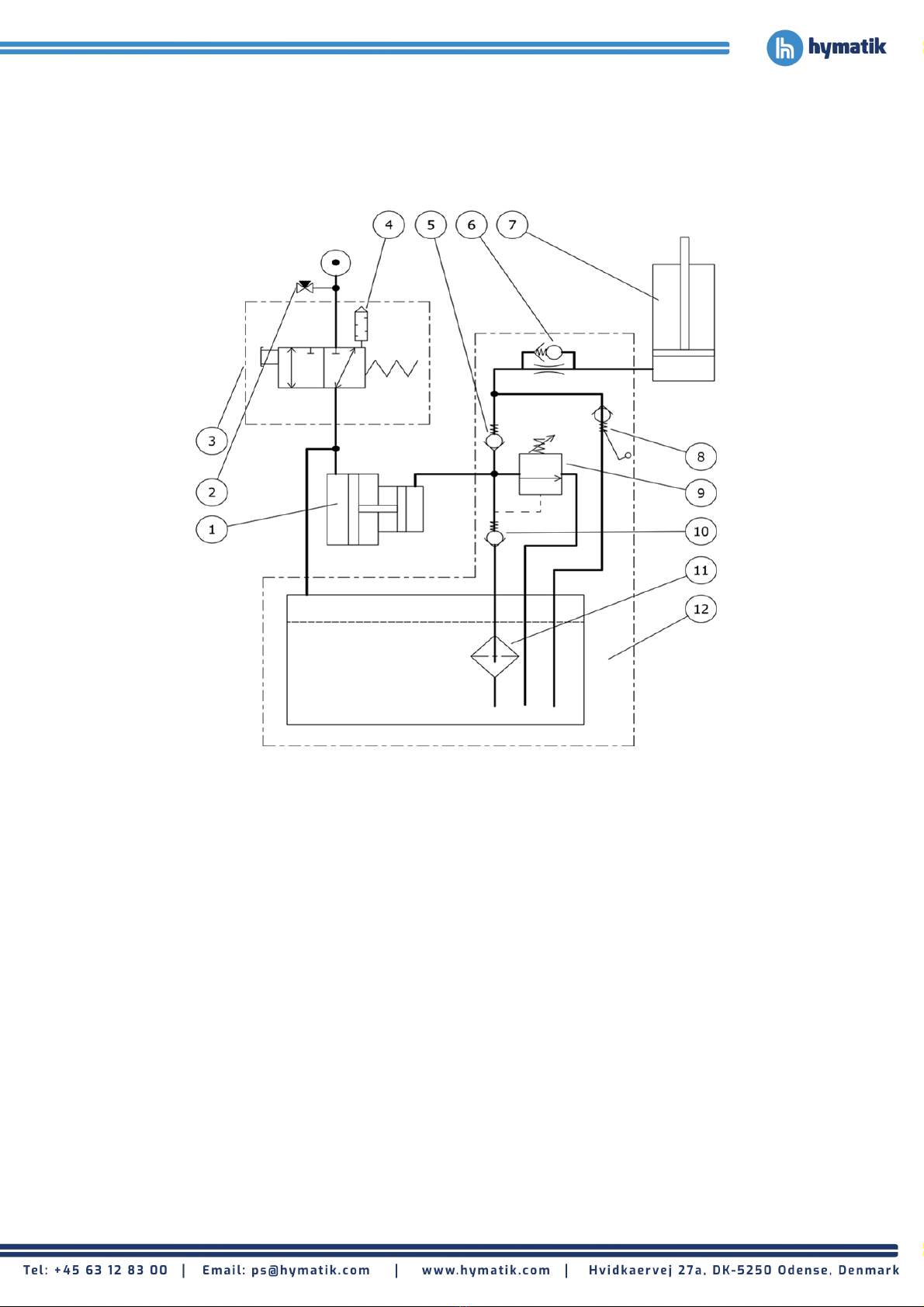

As with all other pneumatic tools, the air motor requires oil

for lubrication of moving parts. It is recommended that an

air supply be used with a filer/water trap and oil lubrication

mechanism.

Monthly: Empty the air supply's water trap and fill the

lubrication mechanism up with oil. Lubricate all movable

parts with oil. At the same time, check jacks and extension

pieces for damage and abnormal wear. For obvious wear of

moving parts, replace them at an authorized workshop with

original spare parts.

Annually: Replace filter (see picture 14,17,18)

Check the safety valve by pulling in the eye or air to whistle

out of the valve 2-3 times (see picture19)

Oil filling: Fill up with oil (see picture 14-16). The correct oil

level is 25 mm below the top edge of the hole, when the

jack is standing horizontally, and the lifting arm is

completely down.

Oil quantity: A1,6T-77 = 0.4 l ; A10T-C = 1.2l.

Oil type: Hydraulic oil with viscosity ISO VG 15, for example

Castrol Hyspin AWH 15, Mobil DTE 10 Excel 15 or the

equivalent.

Never use brake fluid!

Safety inspection:

With respect to national rules - however at least every year

- the following must be checked for by a qualified expert:

Damage, abnormal wear, the saddle for incipient fractures,

pressure relief valve's adjustment, cylinder and pump for

leaks. And also, that labels of safety-related significance are

readable.

If anomalies appear, the jack must not be used

Troubleshooting:

1. The jack cannot lift completely up to the top even though

the pump is running: Fill up the oil, see the oil quantity!

2. The air motor is running slowly or halts: The air pressure

from outside is not sufficient, check the air supply!

3. The load is dropping: check for leaks. Introduce press ball

with mandrel (only authorized personnel).

4. Oil spills from cylinder: Replace cylinder gaskets. Sudden

oil spills from air motor and handle may be due to incorrect

handling, for example if the jack has been laying on its side.

If so, the oil spill (from the oil tank) will stop when the jack

is standing on its wheels again - but the oil will continue to

drip for some hours.

Spare parts:

Always replace worn or defective parts with original spare

parts.

Destruction:

When the jack is to be disposed of after many years of use,

the oil must be drained out and disposed of in a lawful

manner.