Customer Service 8:00am-8:00pm, Monday - Friday EST

Rotary Tool Safety

1-800-840-7856

10

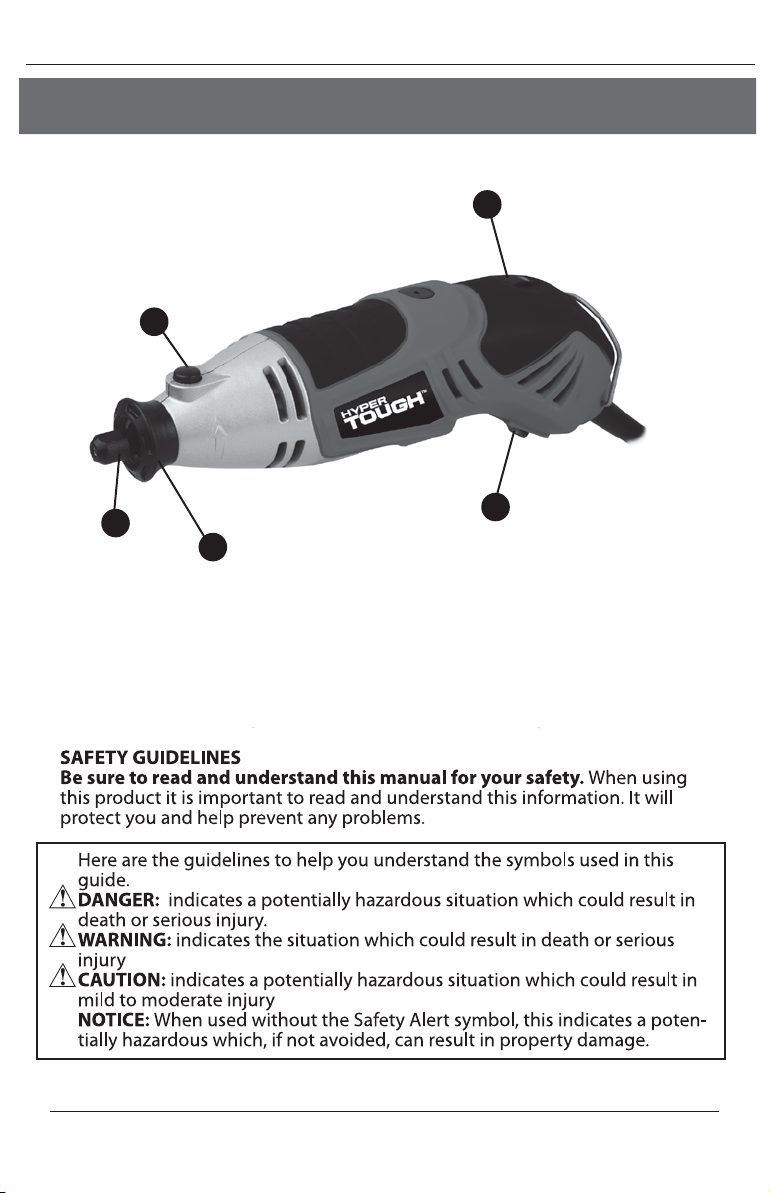

1.5Amp Rotary tool

SAFETY RULES FOR ROTARY TOOLS

1. This power tool is intended to function as a grinder, sander, wire brush, or

polisher. Read all safety warnings, instructions, illustrations and specifications

provided with this power tool. Failure to follow all instructions listed below may result

in electric shock, fire and/or serious injury.

2. Use as intended only. Operations for which the power tool was not designed may

create a hazard and cause personal injury.

3. Do not use accessories which are not specifically designed and recommended

by the tool manufacturer. Just because the accessory can be attached to your power

tool, it does not assure safe operation.

4. The rated speed of the accessory must be at least equal to the maximum speed

marked on the power tool. Accessories running faster than their RATED SPEED can

break and fly apart.

5. The outside diameter and the thickness of your accessory must be within the

capacity rating of your power tool. Incorrectly sized accessories cannot be

adequately guarded or controlled.

6. The arbor size of wheels, flanges, backing pads or any other accessory must

properly fit the collet of the power tool. Accessories with arbor holes that do not

match the mounting hardware of the power tool will run out of balance, vibrate

excessively and may cause loss of control.

7. Do not use a damaged accessory. Before each use inspect the accessory such as

abrasive wheels for chips and cracks, backing pad for cracks, tear or excess wear, wire

brush for loose or cracked wires. If power tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After inspecting and installing an

accessory, position yourself and bystanders away from the plane of the rotating

accessory and run the power tool at maximum no-load speed for one minute.

Damaged accessories will normally break apart during this test time.

8. Wear personal protective equipment. Depending on application, use face

shield, safety goggles or safety glasses. As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron capable of stopping small abrasive or work

piece fragments. The eye protection must be capable of stopping flying debris

generated by various operations. The dust mask or respirator must be capable of

filtering out particles generated by your operation. Prolonged exposure to high

intensity noise may cause hearing loss.

9. Keep bystanders a safe distance away from work area. Anyone entering the

work area must wear personal protective equipment. Fragments of work piece or of a

broken accessory may fly away and cause injury beyond immediate area of operation.

10. Hold power tool by insulated gripping surfaces only, when performing an

operation where the accessory may contact hidden wiring or its own cord. An

accessory contacting a “live” wire may make exposed metal parts of the power tool

“live” and shock the operator.

11. Never lay the power tool down until the accessory has come to a complete

stop. The spinning accessory may grab the surface and pull the power tool out of your

control.

12. Do not run the power tool while carrying it at your side. Accidental contact

with the spinning accessory could snag your clothing, pulling the accessory into your

body.

13. Regularly clean the power tool’s air vents. The motor’s fan will draw the dust

inside the housing and excessive accumulation of powdered metal may cause

electrical hazards.

14. Do not operate the power tool near flammable materials. Sparks could ignite

these materials.

15. Do not use accessories that require liquid coolants. Using water or other liquid

coolants may result in electrocution or shock.

16. Maintain labels and nameplates on the tool. These carry important safety

information.

17. Avoid unintentional starting. Prepare to begin work before turning on the tool.

18. Do not depress the spindle lock when starting or during operation.

19. Do not leave the tool unattended when the Battery Pack is connected. Turn off

the tool, and remove the Battery Pack before leaving.

20. This product is not a toy. Keep it out of reach of children.

21. People with pacemaker should consult their physician(s) before use. Electro-

magnetic fields in close proximity to heart pacemaker could cause pacemaker

interference or pacemaker failure.

SAFETY WARNINGS SPECIFIC FOR GRINDING AND ABRASIVE CUTTING-OFF

OPERATIONS

1. Use only wheel types that are recommended for your power tool and the

specific guard designed for the selected wheel. Wheels for which the power tool

was not designed cannot be adequately guarded and are unsafe.

2. Wheels must be used only for recommended applications. For example: do not

grind with the side of cut-off wheel. Abrasive cut-off wheels are intended for periph-

eral grinding, side forces applied to these wheels may cause them to shatter.

3. Always use undamaged wheel flanges that are of correct size and shape for

your selected wheel. Proper wheel flanges support the wheel thus reducing the

possibility of wheel breakage. Flanges for cut-off wheels may be different from

grinding wheel flanges.

4. Do not use worn down wheels from larger power tools. Wheel intended for

larger power tool is not suitable for the higher speed of a smaller tool and may burst.

5. Dress appropriately. Do not wear pants with cuffs, shirts with open pockets, or any

clothing that can catch and hold hot metal or sparks.

SAFETY WARNINGS SPECIFIC FOR WIRE BRUSHING OPERATIONS

Be aware that wire bristles are thrown by the brush even during ordinary

operation. Do not overstress the wires by applying excessive load to the brush.

The wire bristles can easily penetrate light clothing and/or skin.

VIBRATION SAFETY

This tool vibrates during use. Repeated or long-term exposure to vibration may

cause temporary or permanent physical injury, particularly to the hands, arms

and shoulders. To reduce the risk of vibration-related injury:

1. Anyone using vibrating tools regularly or for an extended period should first

be examined by a doctor and then have regular medical check-ups to ensure

medical problems are not being caused or worsened from use. Pregnant women

or people who have impaired blood circulation to the hand, past hand injuries,

nervous system disorders, diabetes, or Raynaud’s Disease should not use this tool. If

you feel any medical or physical symptoms related to vibration (such as tingling,

numbness, and white or blue fingers), seek medical advice as soon as possible.

2. Do not smoke during use. Nicotine reduces the blood supply to the hands and

fingers, increasing the risk of vibration-related injury.

3. Wear suitable gloves to reduce the vibration effects on the user.

4. Use tools with the lowest vibration when there is a choice between different

processes.

5. Include vibration-free periods each day of work.

6. Grip tool as lightly as possible (while still keeping safe control ). Let the tool do

the work.

7. To reduce vibration, maintain the tool as explained in this manual. If any

abnormal vibration occurs, stop use immediately.

ASSEMBLY

Warning: Always unplug rotary tool before changing accessories, changing

collets or servicing your rotary tool.

USING TOOL

WARNING: Always hold the tool away from your face. Accessories can be

damaged during handling, and can fly apart as they come up to speed.

Collet Nut

To loosen the collet nut (D), first press shaft lock button (C) and rotate the shaft

by hand until the lock engages the shaft preventing further rotation.

CAUTION: Do not engage lock while the Rotary Tool is running.

With the shaft lock engaged, use the collet wrench to

loosen the collet nut if necessary. The collet nut must

be loosely threaded on when inserting an accessory.

Change accessories by inserting the new one into the

collet as far as possible to minimize run out and

unbalance.

With the shaft lock engaged, finger tighten the collet

nut until the accessory shank is gripped by the collet.

Using wrench, completely tighten to fully secure the accessory.

NOTE: Avoid excessive tightening of the collet nut when there is no bit inserted.

Collets

Three different size collets (1/16",3/32" and 1/8" ) to

accommodate different shank sizes are available for

your Rotary Tool.

To install a different collet, unscrew to remove the collet nut(D) and

pull out the old collet. Insert the unslotted end of the

collet in the hole in the end of the tool shaft. Replace

collet nut on the shaft.

CAUTION: Always use the collet which matches the

shank size of the accessory you plan to use. Never force a

larger diameter shank into a collet.

Operating speeds:

This tool has a variable speed dial. Listed below are the

average no-load speed.

1 - 8000

2 - 12500

3 - 17000

4 - 21500

5 - 26000

6 - 30500

MAX – 35000

• Speed may vary by tool (up to 10%).

Rules About Speed:

1. Plastic and other materials that melt at low temperatures should be cut at low

speeds to prevent damaging the material.

2. Polishing, buffing and cleaning with any type of bristle brush must be done at

speeds not greater than 15,000 RPM to prevent damage to the brush from bristles

flying toward operator.

3. Carving, Cutting & Shaping Wood should be performed at higher speeds.

4. Increasing pressure does not equal increased performance, try using a different

accessory or increasing speed.

5. Aluminum, copper alloys, lead alloys, zinc alloys and tin may be cut at various

speeds, depending on the type of cutting being done. Use paraffin or other suitable

lubricant on the cutter to prevent the cut material from adhering to the cutter teeth.

6. Iron and steel should be cut at high speed. If the tool starts to "chatter" While

cutting iron or steel, it means it is running too slow

PUTTING ACCESSORIES IN TOOL

1. Press down the shaft lock button and hold it down

2. Apply the collet wrench to the flats of the collet nut

and turn it counterclockwise to loosen it.

3. Place the accessories shank into the collet as deep

as it will go.

4. Press and hold the shaft lock button

5. Tighten the collet nut by turning it finger tight in a clockwise direction until the

accessory is firmly clamped. Completely tighten using wrench.

WARNING: To avoid accidents, always be sure the tool is turned “OFF”before

cleaning.

Protect the tool and its parts and accessories from moisture and humidity.

IMPORTANT: to assure product SAFETY and RELIABILITY, all maintenance, repairs

or adjustments (other than those mentioned in this manual) should be

performed by authorized repair centers using identical replacement parts.

WARNING: Only use recommended accessories-use of unauthorized accessories

can be hazardous and /or result in injury or damage.

This product contains lead, a chemical known to the State of California to cause

cancer, and birth defects or other reproductive harm.

Battery posts, terminals and related accessories contain lead and lead

compounds, chemicals known to the State of California to cause cancer and

reproductive harm.

Wash hands after handling.

Unplug the rotary tool. Loosen the plastic cover by wrench, remove the old carbon

brush, put new one into the tool.

ACCESSORIES

If you need accessories for use with your tool, most recommended accessories are

available from your local retailer. If you need accessory information, please call

1-800-840-7856.