Safety Practices

안전 조항

2<< Vacuum Contactor Instruction Manual

Safety Practices

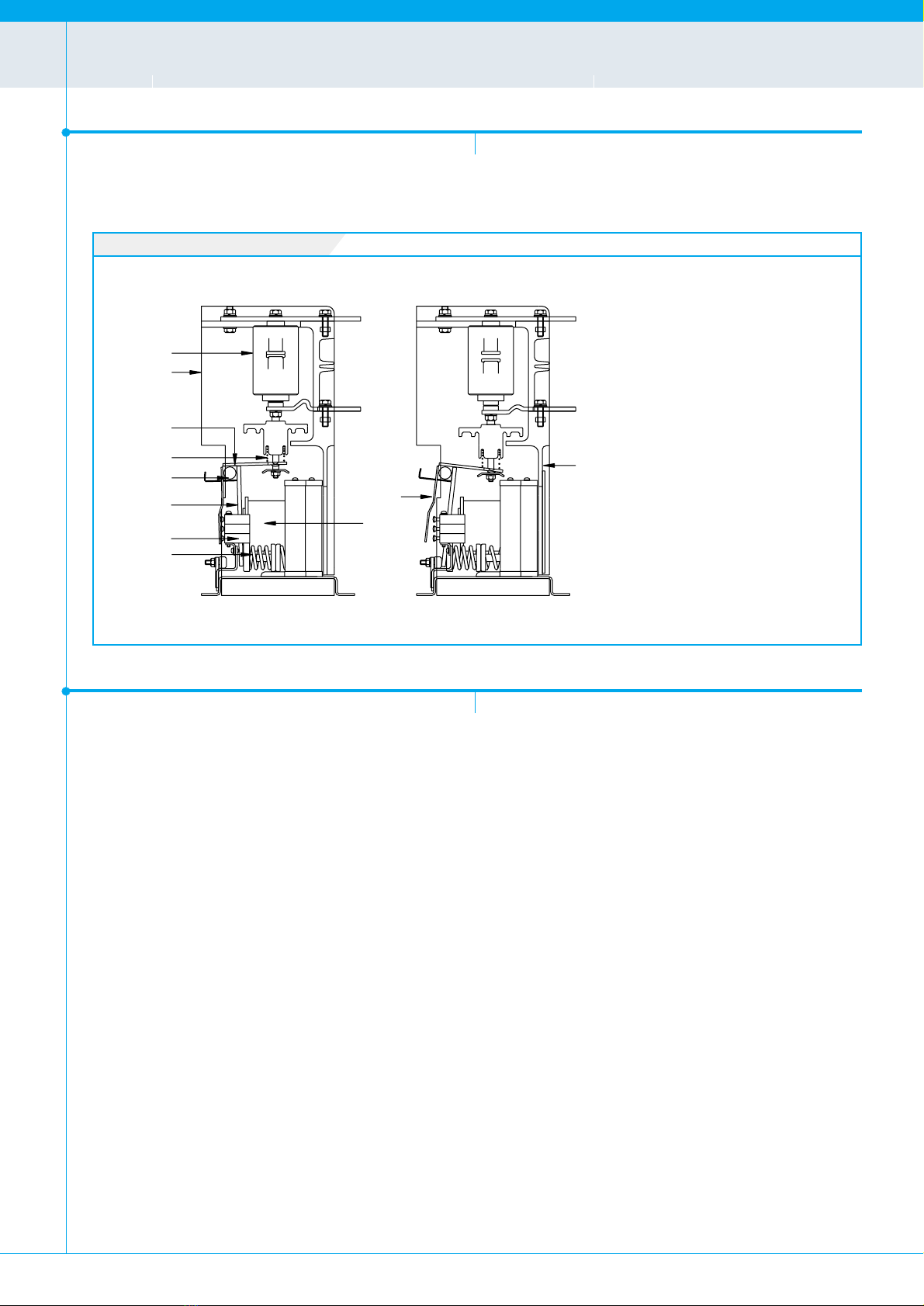

This instruction manual applies only to the HCA Series

vacuum contactor regarding installation and

maintenance procedures.

Installing and maintaining these products improperly may

result in serious personal injury, property damage, or even

death. Therefore this instruction manual must be read and

understood at any step in unpacking, assembly, operation,

and maintenance of contactors.

Only qualified persons who are familiar with installing and

maintaining contactors are permitted to work on

contactors, and this instruction manual should be

accessible to those persons at any time.

If further information is required, please contact Hyundai

Heavy Industries Co., Ltd.

Signal Words

Signal words used in this instruction manual are divided by

DANGER, WARNING and CAUTION depending on the situation.

Indicates an imminently hazardous point which, if ignored,

will result in death or serious injury.

This is the most dangerous point.

Indicates a potentially hazardous point which, if ignored,

could result in death or serious injury.

Indicates a potentially hazardous point which, if ignored,

may result in minor or moderate injury.

This signal also warns operators not to work unsafely.

Safety Practices During Installation

안전 조항

기호 설명

설치(취부, 접속)시의 주의사항

Excessive heavy weight could cause he

serious injury, or damage. To avoid this

situation, please don’t transport a contactor

on a lifting facility in the raised position.

Do not work on contactors unless the primary

circuits are disconnected by the visible breaker.

When connecting bus-bars, tighten bolts

according to our standards.

Contactors should be tightly mounted on a

horizontal plane.

Do not install the contactors in areas with

high temperature, high humidity, dust,

corrosive or vibrating conditions.

Concrete dust or any other dust should not

be inside of the product when it installed.

It can cause fire or misoperation.