Hi4 Robot Driver

GP-Pro EX Device/PLC Connection Manual 4

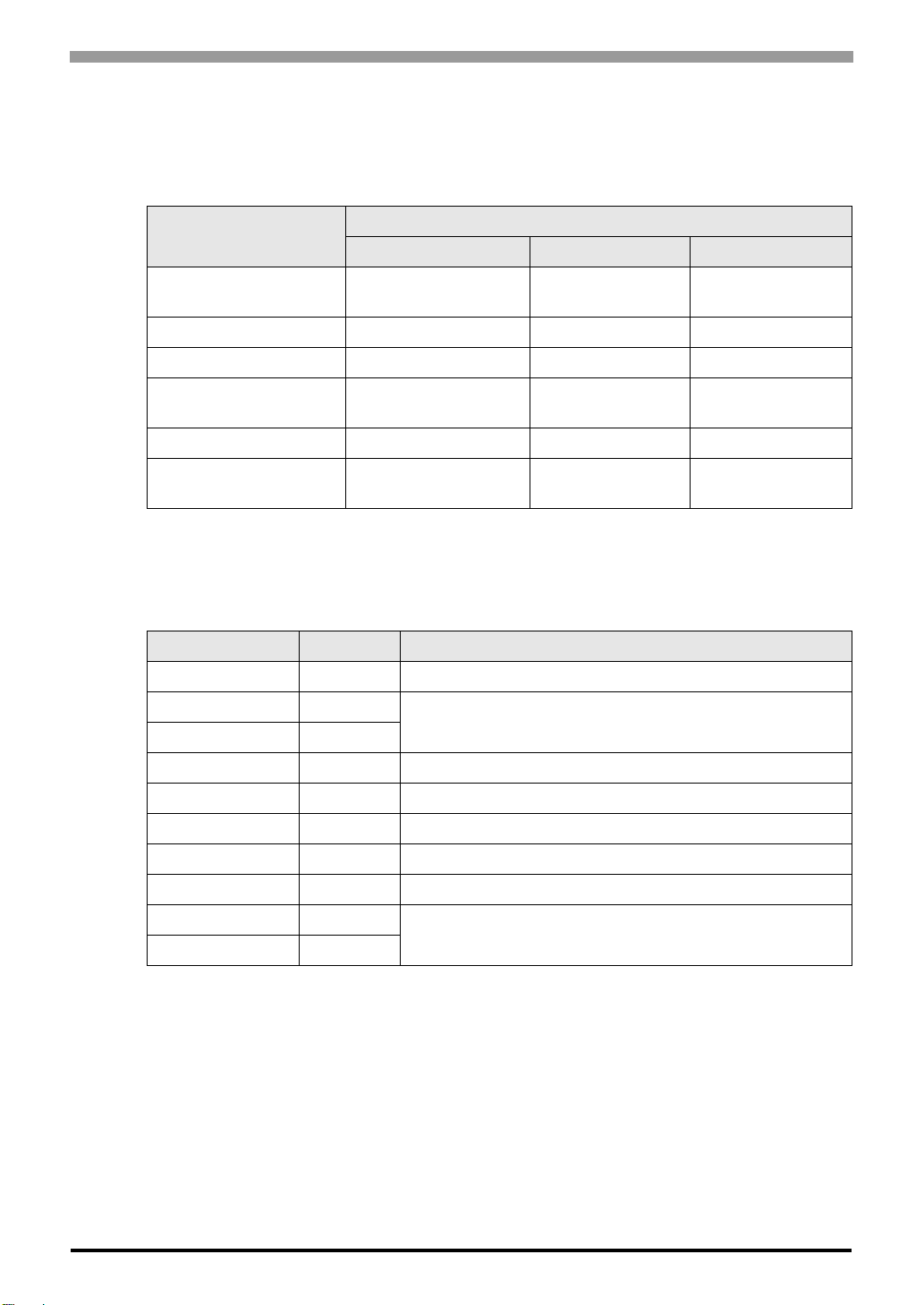

COM Port of IPC

When connecting IPC with External Device, the COM port which can be used changes with series and SIO type.

Please refer to the manual of IPC for details.

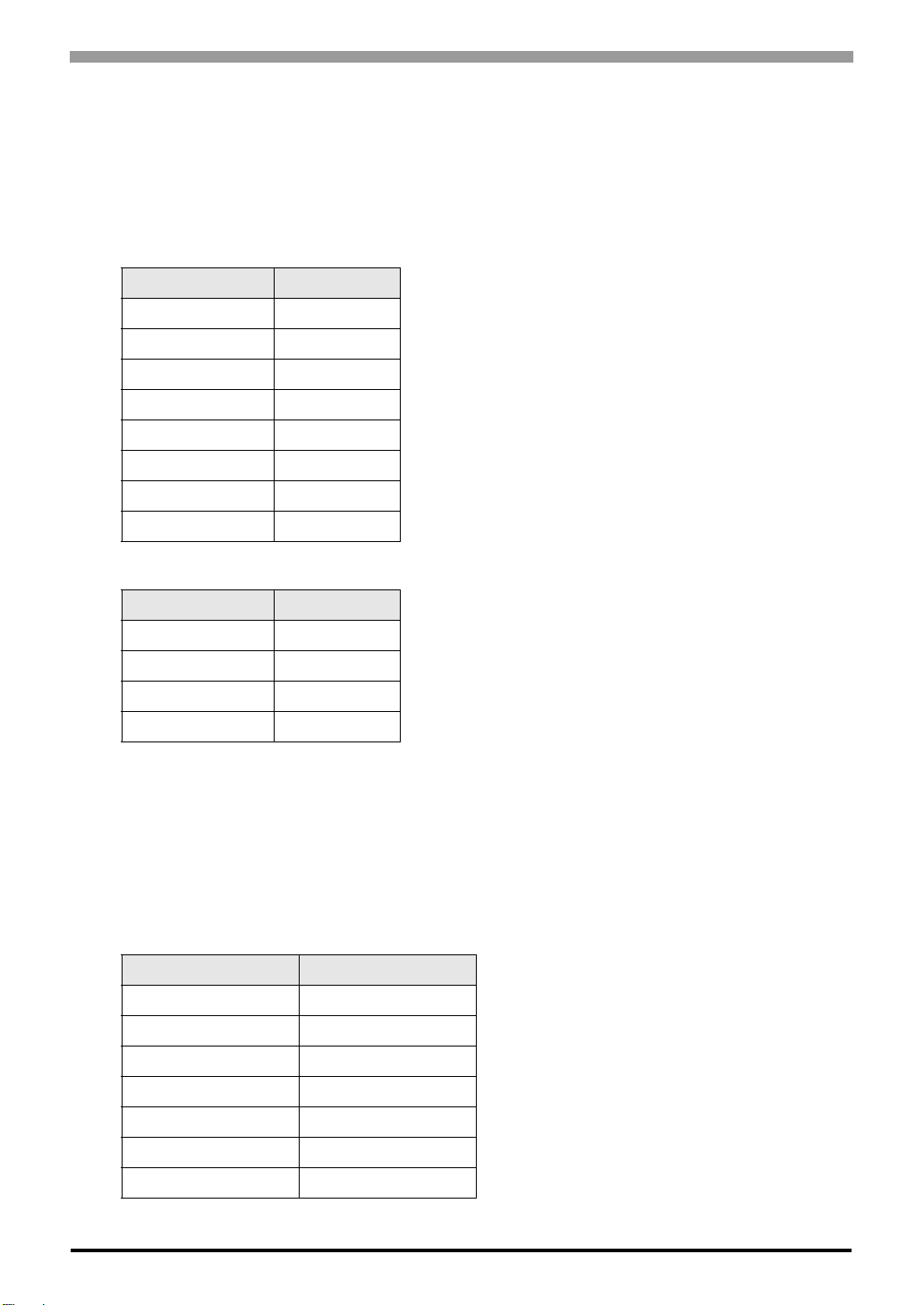

Usable port

Dip switch setting: RS-232C

Series Usable port

RS-232C RS-422/485(4 wire) RS-422/485(2 wire)

PS-2000B COM1*1 , COM2,

COM3*1, COM4

*1 The RI/5V can be switched. Please switch with the change switch of IPC.

--

PS-3450A, PS-3451A COM1, COM2*1*2 COM2*1*2 COM2*1*2

PS-3650A, PS-3651A COM1*1 --

PS-3700A (Pentium®4-M)

PS-3710A COM1*1, COM2*1,

COM3*2 , COM4

*2 It is necessary to set up the SIO type with the Dip switch. Please set up as follows according to SIO

type to be used.

COM3*2 COM3*2

PS-3711A COM1*1, COM2*2 COM2*2 COM2*2

PL-3000B COM1*1*2, COM2*1,

COM3, COM4 COM1*1*2 COM1*1*2

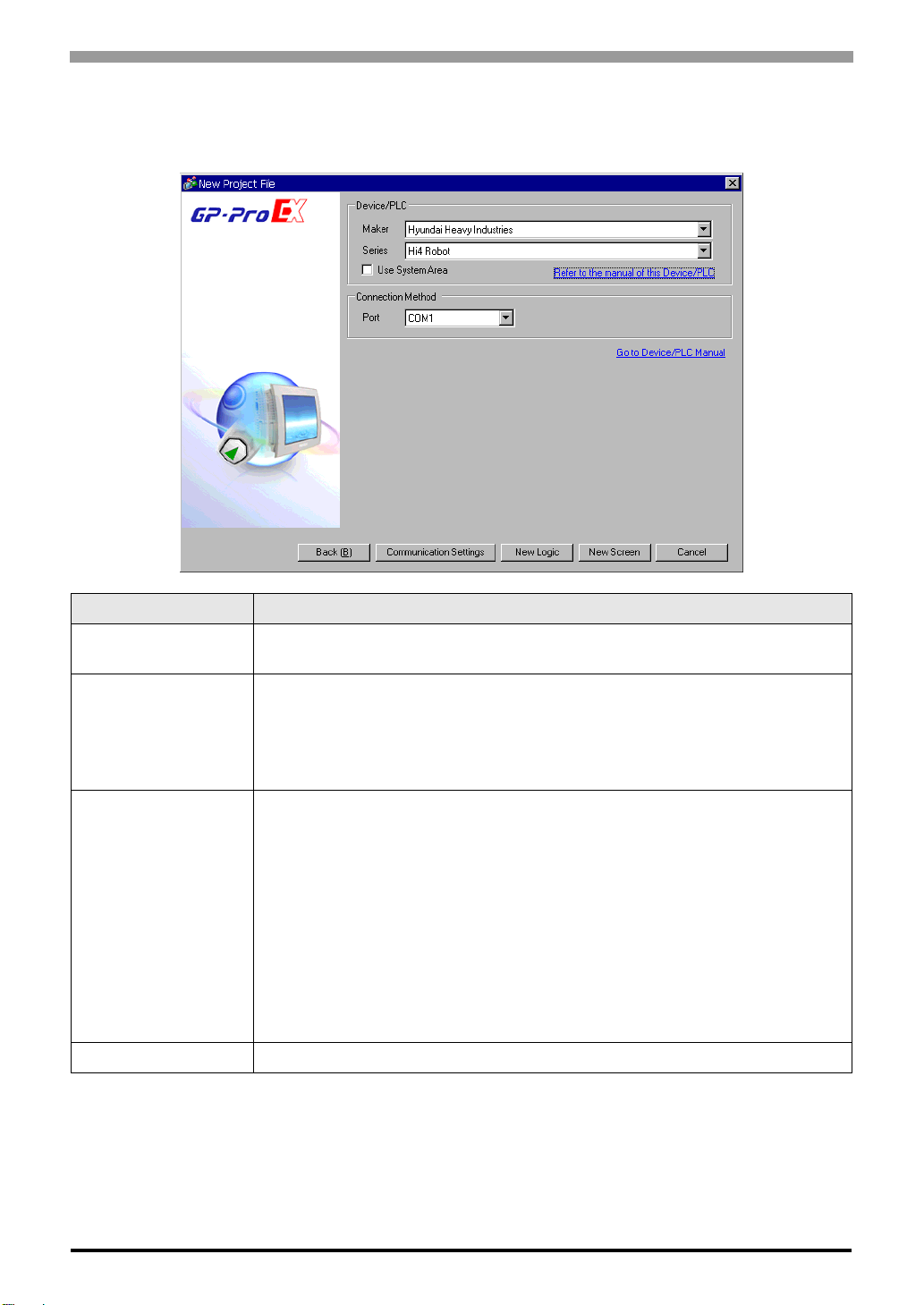

Dip switch Setting Description

1OFF

*1

*1 It is necessary to turn ON the set value, only when using PS-3450A and PS-3451A.

Reserve (always OFF)

2OFF

SIO type: RS-232C

3OFF

4 OFF Output mode of SD (TXD) data: Always output

5 OFF Terminal resistance (220Ω) insertion to SD (TXD): None

6 OFF Terminal resistance (220Ω) insertion to RD (RXD): None

7 OFF Short-circuit of SDA (TXA) and RDA (RXA): Does not Exist

8 OFF Short-circuit of SDB (TXB) and RDB (RXB): Does not Exist

9OFF

RS (RTS) Auto control mode: Disable

10 OFF