CONTENTS

EC declaration of conformity

-----------------------------

0-1

Foreword

-----------------------------------------------------------

0-2

Emission-related components warranty

(USA and CANADA only)

---------------------------------

0-2-1

Before servicing this machine

---------------------------

0-3

Table to enter S/No and distribution

---------------------

0-4

EC regulation approved

------------------------------------

0-5

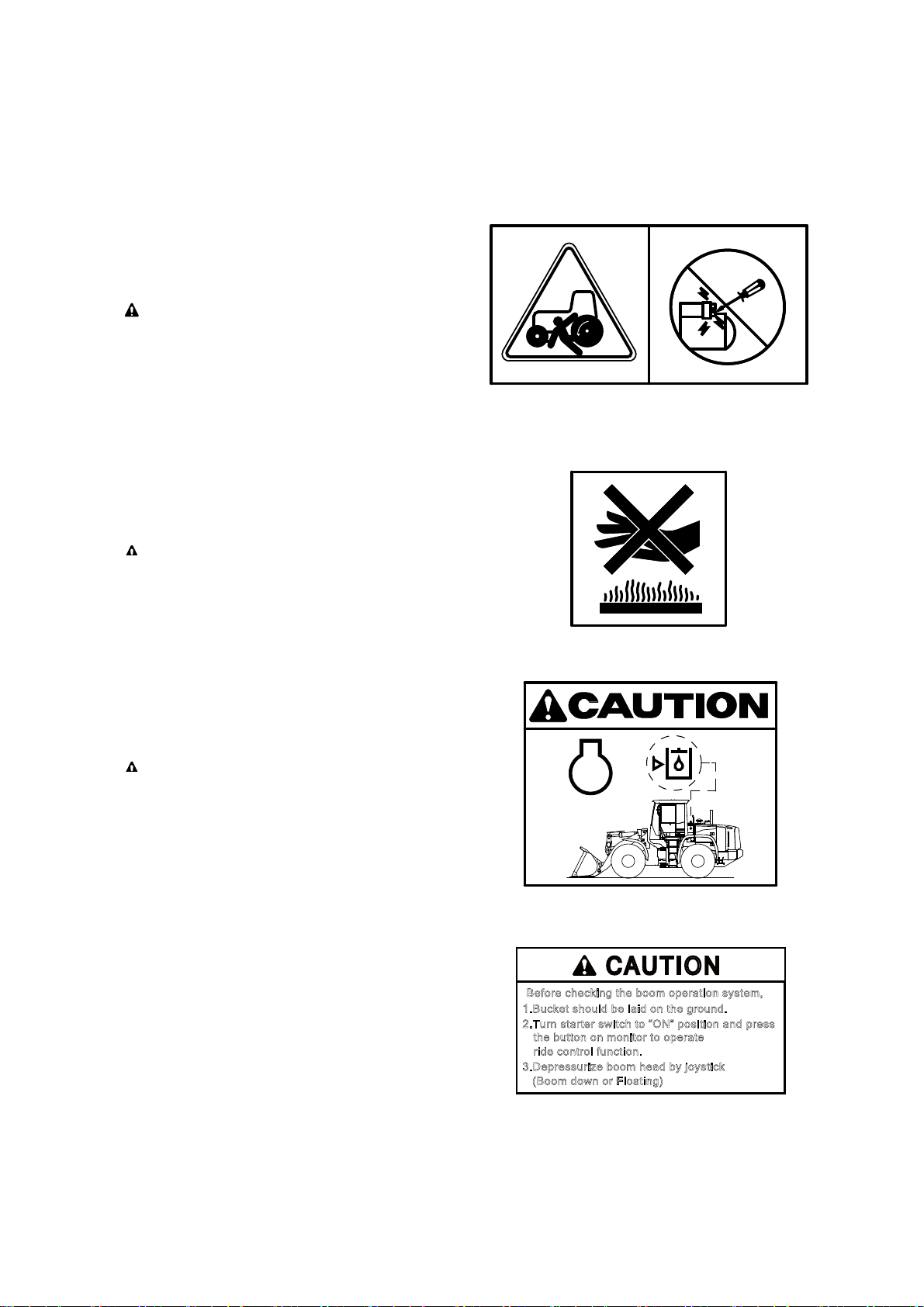

Safety labels

------------------------------------------------------

0-6

Machine data plate

--------------------------------------------

0-17

Guide (direction, S/No, symbol)

------------------------

0-18

1.SAFETY HINTS

1.California proposition 65

----------------------------

1-1

2.Safety rules

------------------------------------------------

1-2

2.SPECIFICATIONS

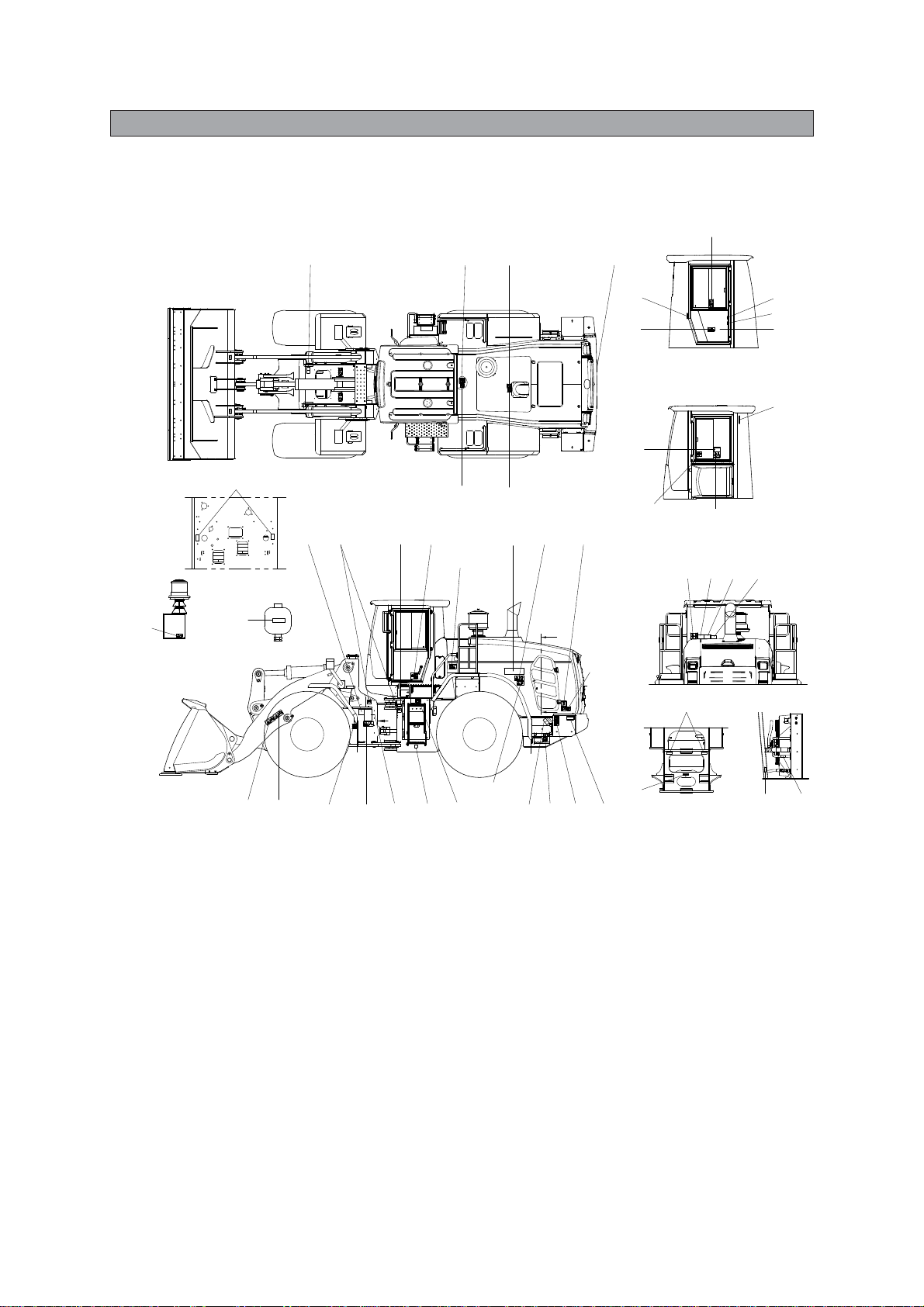

1.Major components

--------------------------------------

2-1

2.Specifications

----------------------------------------------

2-2

3.Weight

---------------------------------------------------------

2-6

4.Specification for major components

-----------

2-7

3.CONTROL DEVICES

1.Cab devices

------------------------------------------------

3-1

2.Cluster

--------------------------------------------------------

3-2

3.Monitors

------------------------------------------------------

3-13

4.Switches

-----------------------------------------------------

3-44

5.Control device

---------------------------------------------

3-49

6.Air conditioner and heater

--------------------------

3-53

7.Others

---------------------------------------------------------

3-56

4.OPERATION

1.Suggestion for new machine

----------------------

4-1

2.Check before starting the engine

---------------

4-2

3.Starting and stop the engine

----------------------

4-3

4.Warming-up operation

--------------------------------

4-8

5.Operation of the working device

-----------------

4-9

6.Traveling of the machine

-----------------------------

4-10

7.Efficient working method

----------------------------

4-15

8.Adjustment of the work equipment

-------------

4-22

9.Operation in the special work sites

-------------

4-23

10.Storage

--------------------------------------------------------

4-25

11.Exhaust system cleaning

------------------------------

4-27

12.Open the engine hood

----------------------------------

4-28

13.Attachment manually lowering

----------------------

4-31

5.

TRANSPORTATION

1.Road traveling

--------------------------------------------

5-1

2.Preparation for transportation

--------------------

5-2

3.Loading the machine

---------------------------------

5-3

4.Fixing the machine

-------------------------------------

5-4

5.Loading and unloading by crane

----------------

5-6

6.Towing the machine

-------------------------------------

5-7

6.MAINTENANCE

1.Instructions

-------------------------------------------------

6-1

2.Tightening torque

---------------------------------------

6-5

3.Spec of fuel, coolant and lubricants

-----------

6-8

4.Maintenance check list

-------------------------------

6-10

5.Maintenance chart

-------------------------------------

6-13

6.Service instruction

-------------------------------------

6-15

7.Electrical system

----------------------------------------

6-53

8.Air conditioner and heater

--------------------------

6-56

7.TROUBLESHOOTING GUIDE

1.Engine

--------------------------------------------------------

7-1

2.Electrical system

----------------------------------------

7-2

3.Power train system

---------------------------------------

7-3

4.Hydraulic system

---------------------------------------

7-4

8. OTHERS

1.Central grease lubrication system

-----------

8-1

2.Quick coupler

-------------------------------------------

8-9

INDEX

------------------------------------------------------------

9-1