HX260FC T3

5

Prevention of burn

After stopping the equipment, conduct inspection and maintenance once temperature of the

equipment is cooled down. Be careful about getting burned by hot oil. Gear oil, operating oil,

high pressure hose and other pipe parts reach high temperature during operation.

Preparation of firefighting system

Be prepared for emergency injury or fire. Always keep first-aid kits and fire extinguisher ready.

In particular, be aware of how to use the fire extinguisher. Keep a memo on emergency contact

information such as phone numbers of hospitals, ambulances and fire stations.

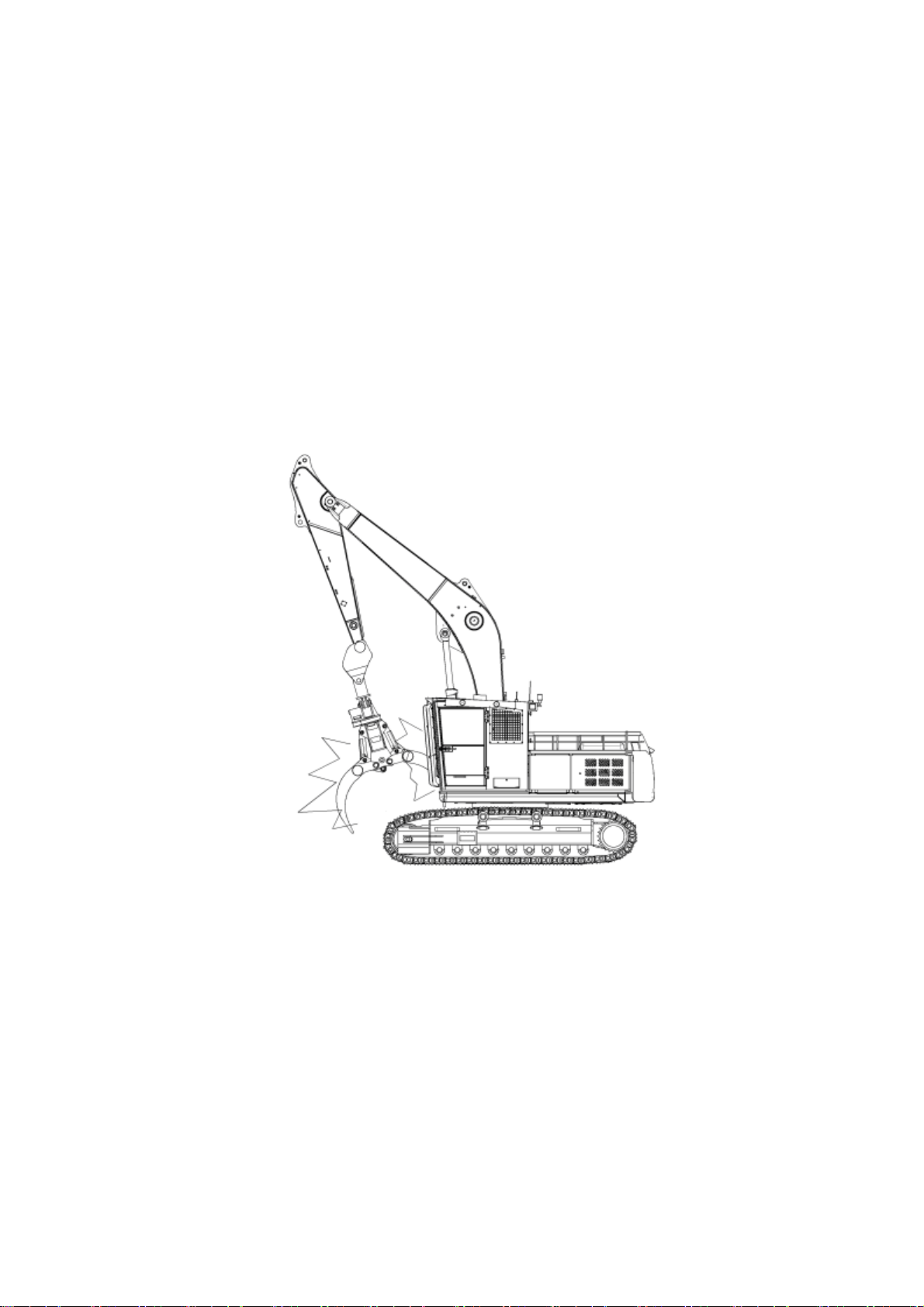

Injury from attach and working devices

Be careful about rolling of hands, feet and body parts into operating parts such as between the

equipment and working devices, working devices and cylinder, etc. Narrowing of distance by

operation of operating devices can lead to serious human accidents.

Operation with window closed

During operation of the equipment, persons other than the operator must escape from the scope

of scattered and fallen objects that can occur during work.

Securing workplace safety

Check risk factors in the workplace before work. Decide the safest work method after

confirming the work environment.

Communication

Inaccurate communication can cause accidents. When working in groups, make sure that

workers understand hand signals of one another.