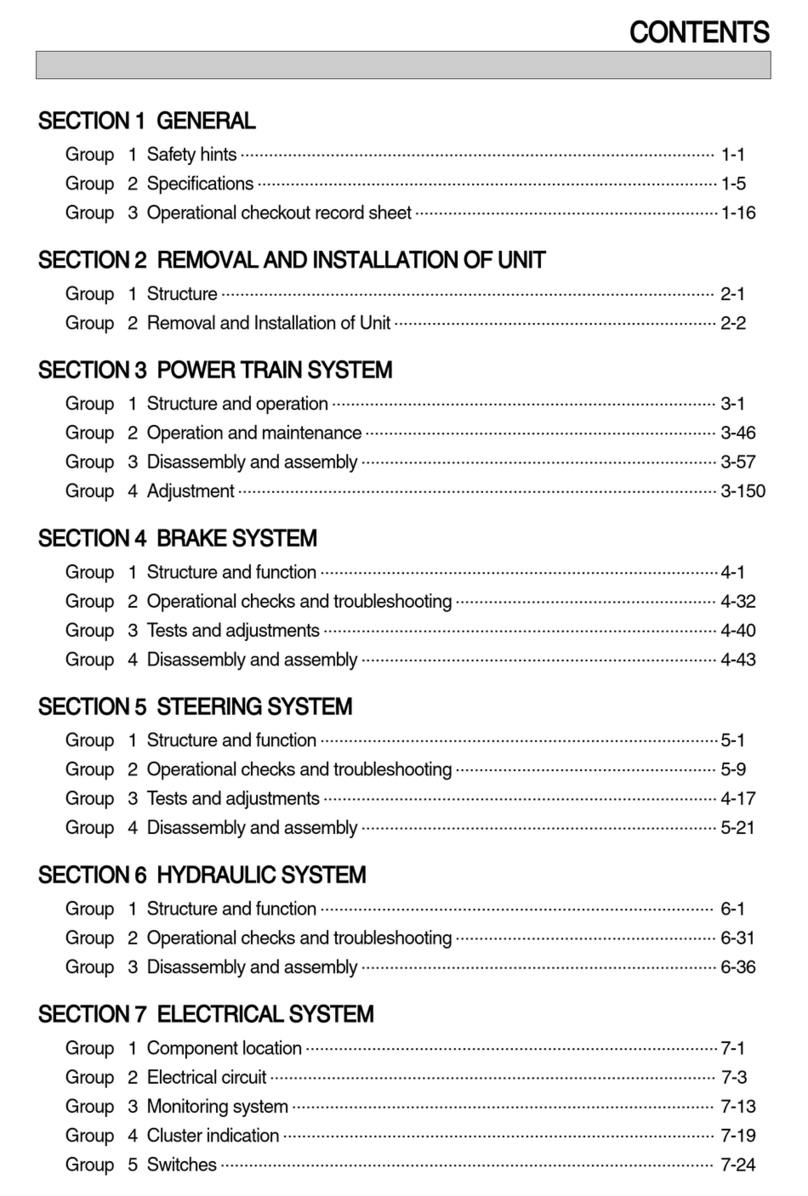

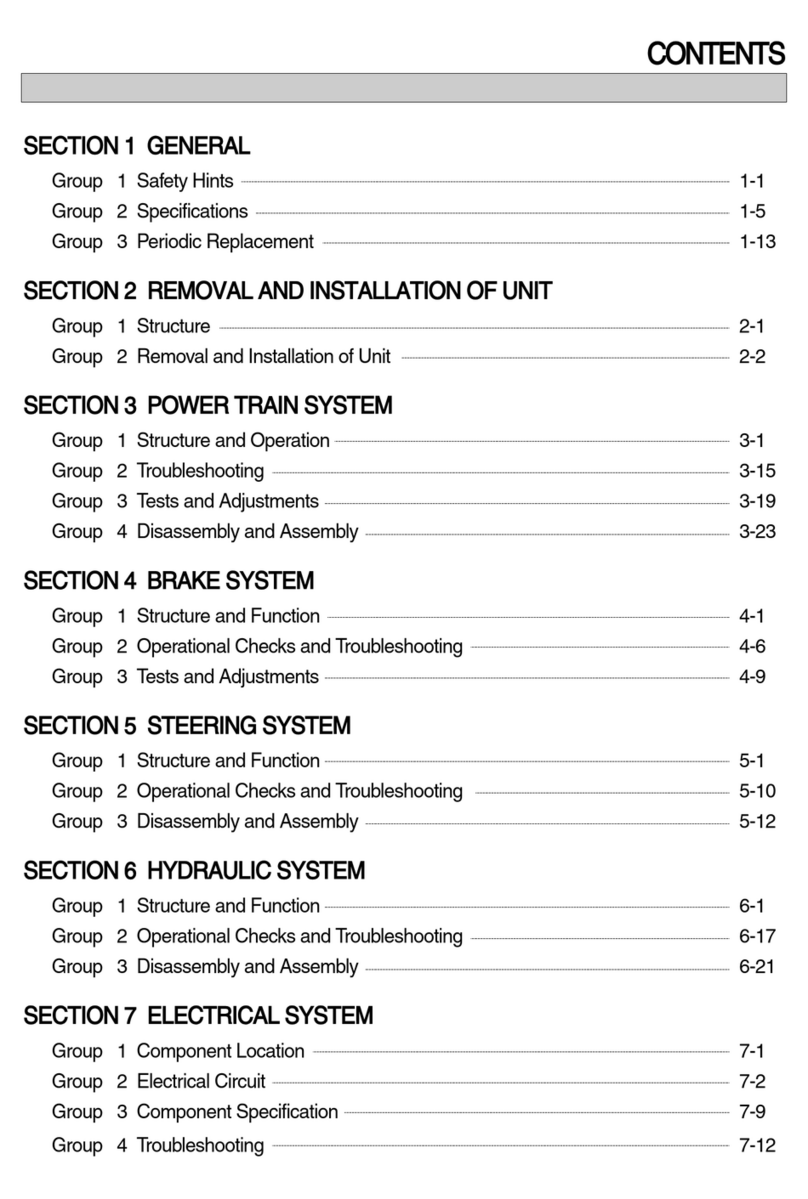

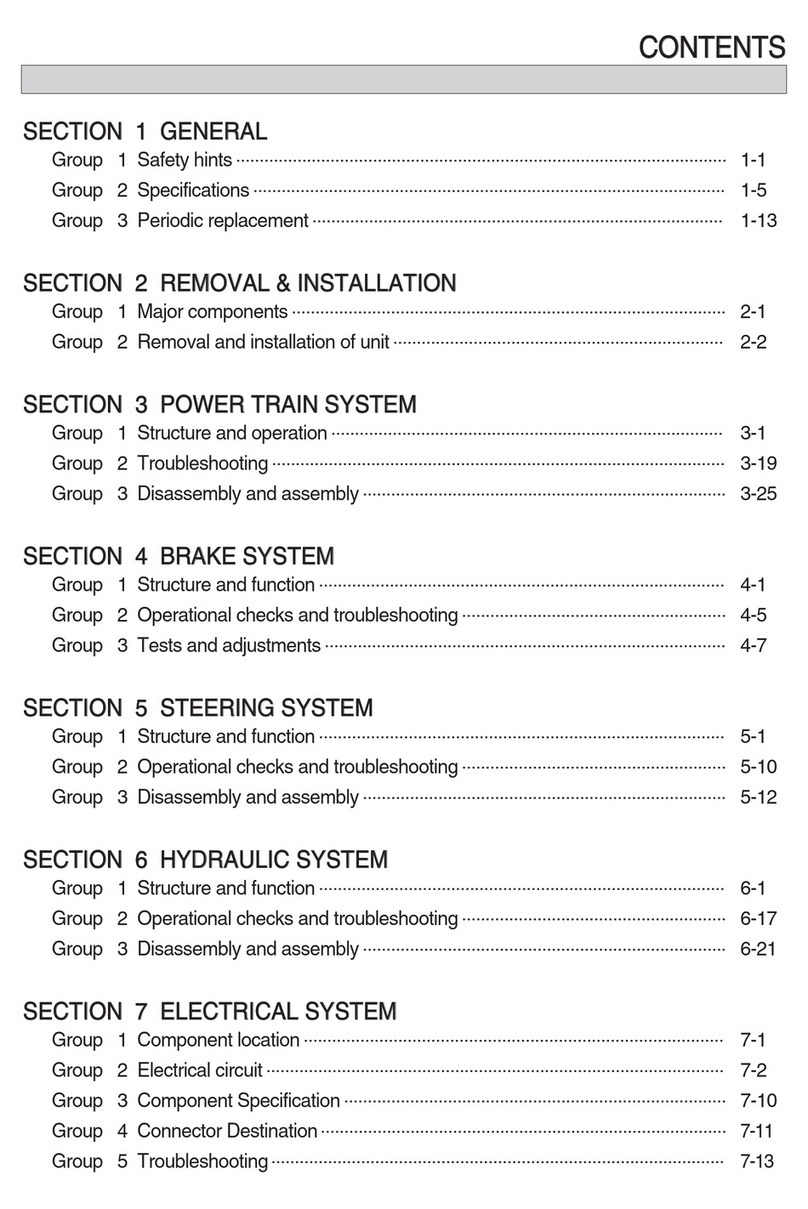

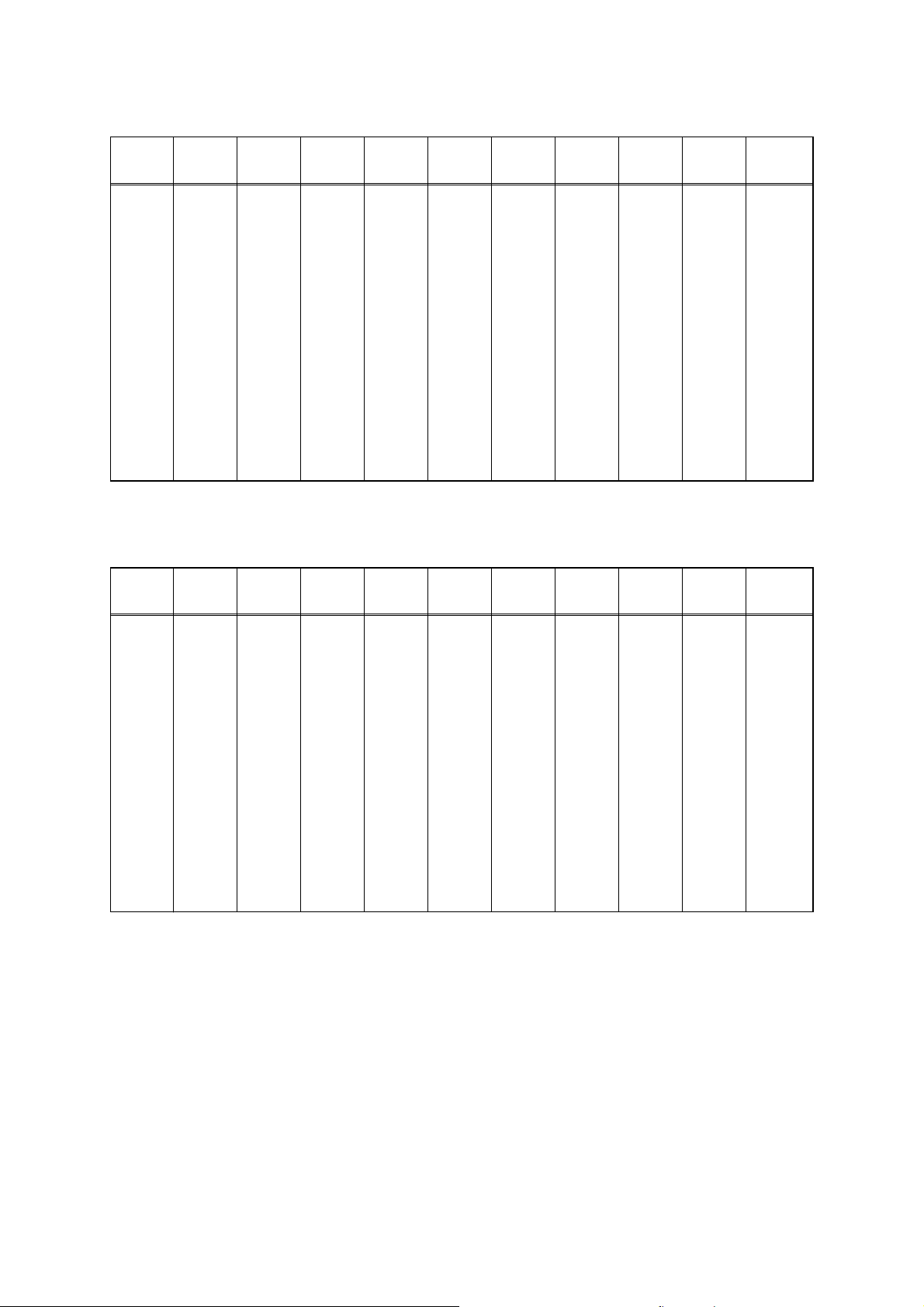

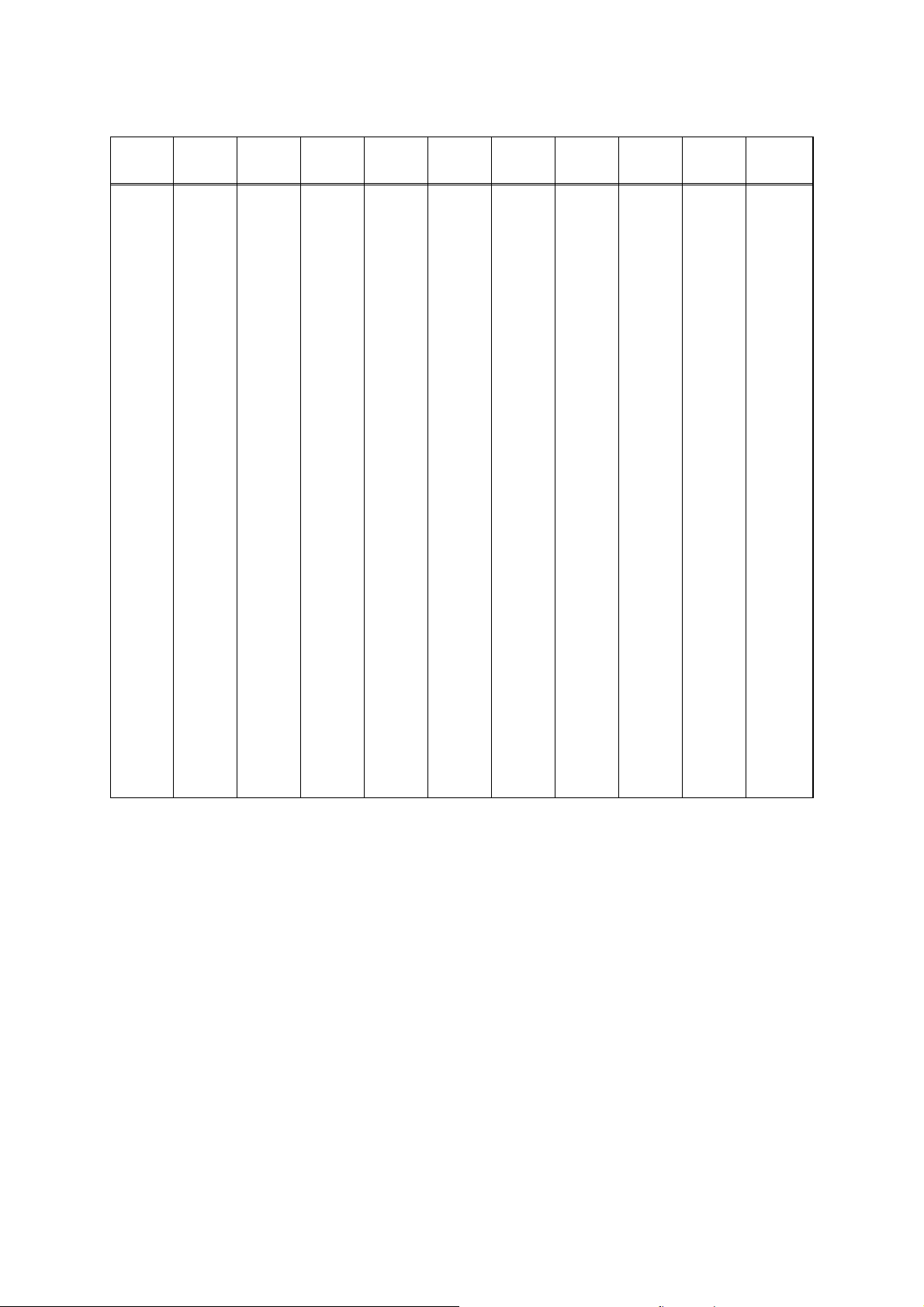

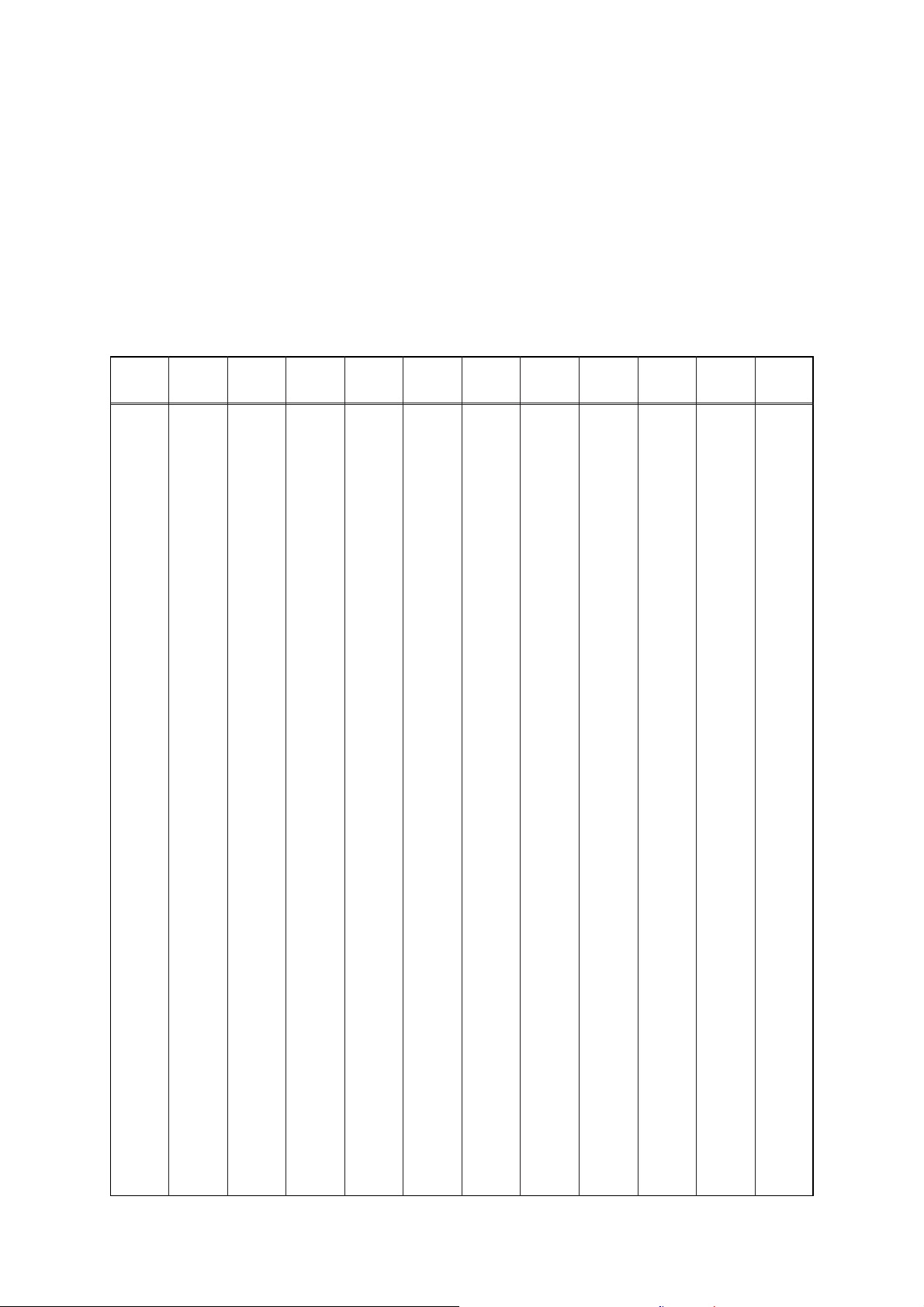

TEMPERATURE

Fahrenheit-Centigrade Conversion.

A simple way to convert a fahrenheit temperature reading into a centigrade temperature reading or vice

verse is to enter the accompanying table in the center or boldface column of figures.

These figures refer to the temperature in either Fahrenheit or Centigrade degrees.

If it is desired to convert from Fahrenheit to Centigrade degrees, consider the center column as a table of

Fahrenheit temperatures and read the corresponding Centigrade temperature in the column at the left.

If it is desired to convert from Centigrade to Fahrenheit degrees, consider the center column as a table

of Centigrade values, and read the corresponding Fahrenheit temperature on the right.

0-8

ÁCÁFÁCÁFÁCÁFÁCÁF

-40.4 -40 -40.0 -11.7 11 51.8 7.8 46 114.8 27.2 81 117.8

-37.2 -35 -31.0 -11.1 12 53.6 8.3 47 116.6 27.8 82 179.6

-34.4 -30 -22.0 -10.6 13 55.4 8.9 48 118.4 28.3 83 181.4

-31.7 -25 -13.0 -10.0 14 57.2 9.4 49 120.2 28.9 84 183.2

-28.9 -20 -4.0 -9.4 15 59.0 10.0 50 122.0 29.4 85 185.0

-28.3 -19 -2.2 -8.9 16 60.8 10.6 51 123.8 30.0 86 186.8

-27.8 -18 -0.4 -8.3 17 62.6 11.1 52 125.6 30.6 87 188.6

-27.2 -17 1.4 -7.8 18 64.4 11.7 53 127.4 31.1 88 190.4

-26.7 -16 3.2 -6.7 20 68.0 12.8 55 131.0 32.2 90 194.0

-26.1 -15 5.0 -6.7 20 68.0 12.8 55 131.0 32.2 90 194.0

-25.6 -14 6.8 -6.1 21 69.8 13.3 56 132.8 32.8 91 195.8

-25.0 -13 8.6 -5.6 22 71.6 13.9 57 134.6 33.3 92 197.6

-24.4 -12 10.4 -5.0 23 73.4 14.4 58 136.4 33.9 93 199.4

-23.9 -11 12.2 -4.4 24 75.2 15.0 59 138.2 34.4 94 201.2

-23.3 -10 14.0 -3.9 25 77.0 15.6 60 140.0 35.0 95 203.0

-22.8 -9 15.8 -3.3 26 78.8 16.1 61 141.8 35.6 96 204.8

-22.2 -8 17.6 -2.8 27 80.6 16.7 62 143.6 36.1 97 206.6

-21.7 -7 19.4 -2.2 28 82.4 17.2 63 145.4 36.7 98 208.4

-21.1 -6 21.2 -1.7 29 84.2 17.8 64 147.2 37.2 99 210.2

-20.6 -5 23.0 -1.1 35 95.0 21.1 70 158.0 51.7 125 257.0

-20.0 -4 24.8 -0.6 31 87.8 18.9 66 150.8 40.6 105 221.0

-19.4 -3 26.6 0 32 89.6 19.4 67 152.6 43.3 110 230.0

-18.9 -2 28.4 0.6 33 91.4 20.0 68 154.4 46.1 115 239.0

-18.3 -1 30.2 1.1 34 93.2 20.6 69 156.2 48.9 120 248.0

-17.8 0 32.0 1.7 35 95.0 21.1 70 158.0 51.7 125 257.0

-17.2 1 33.8 2.2 36 96.8 21.7 71 159.8 54.4 130 266.0

-16.7 2 35.6 2.8 37 98.6 22.2 72 161.6 57.2 135 275.0

-16.1 3 37.4 3.3 38 100.4 22.8 73 163.4 60.0 140 284.0

-15.6 4 39.2 3.9 39 102.2 23.3 74 165.2 62.7 145 293.0

-15.0 5 41.0 4.4 40 104.0 23.9 75 167.0 65.6 150 302.0

-14.4 6 42.8 5.0 41 105.8 24.4 76 168.8 68.3 155 311.0

-13.9 7 44.6 5.6 42 107.6 25.0 77 170.6 71.1 160 320.0

-13.3 8 46.4 6.1 43 109.4 25.6 78 172.4 73.9 165 329.0

-12.8 9 48.2 6.7 44 111.2 26.1 79 174.2 76.7 170 338.0

-12.2 10 50.0 7.2 45 113.0 26.7 80 176.0 79.4 172 347.0