~1~

1. Safety regulations

When operating the truck, one should always wear safe shoes.

When assembling or disassembling the truck, in order to avoid injury, one should

always wear safety goggles.

Attention!

When the truck is damaged or failure-affecting safety occurs, do not go on

operating the truck.

Attention!

The designed truck can only be used on hard and smooth ground.

In the following environmental situations, it is not allowed to operate the truck:

- The air contains dust or gas, which may be able to cause fire or explosion.

- In refrigerating warehouse or some low temperature, salt containing or other

corrosive environments.

- Raining outdoor environment

- Operation on granule or grassland

Attention!

- When operating the truck, careful judgement should be conducted and one

should operate in a responsible manner.

- One should not operate the truck with hand or shoes with oil.

- The operator must not wear loose clothes or jewelry.。

Attention!

- When operating the truck, it should be ensured that the ground possess

sufficient load bearing capacity and the load here refers to the sum of the weight

of the truck and the weight of the goods.

- When there is a protruding object on the truck or around it, which may cause

human injury or forklift damage, one must be very careful.

-- It is strictly prohibited for people to appear around the truck operation

area, which may cause human injury, for example, when goods fall down.

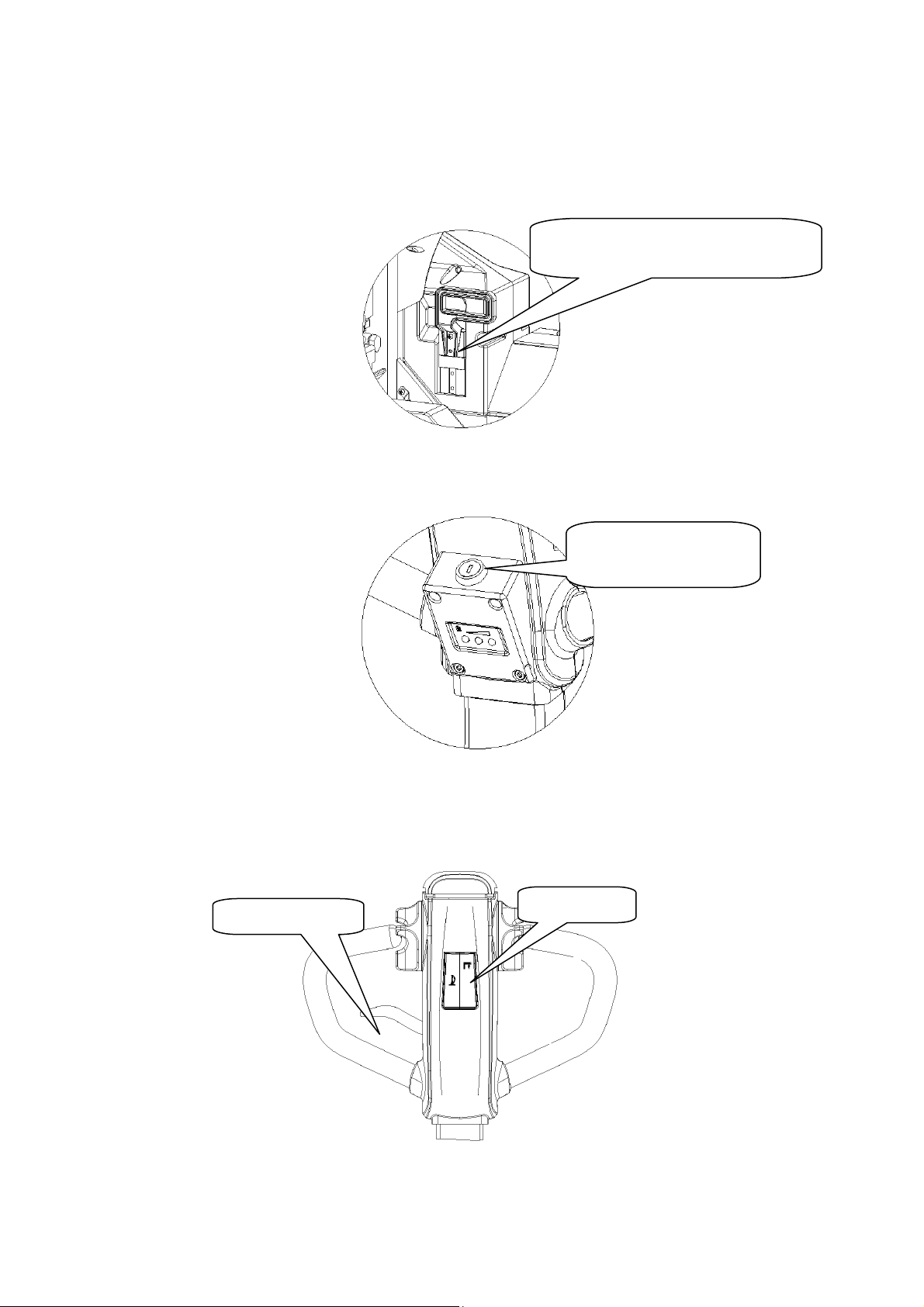

Be careful!

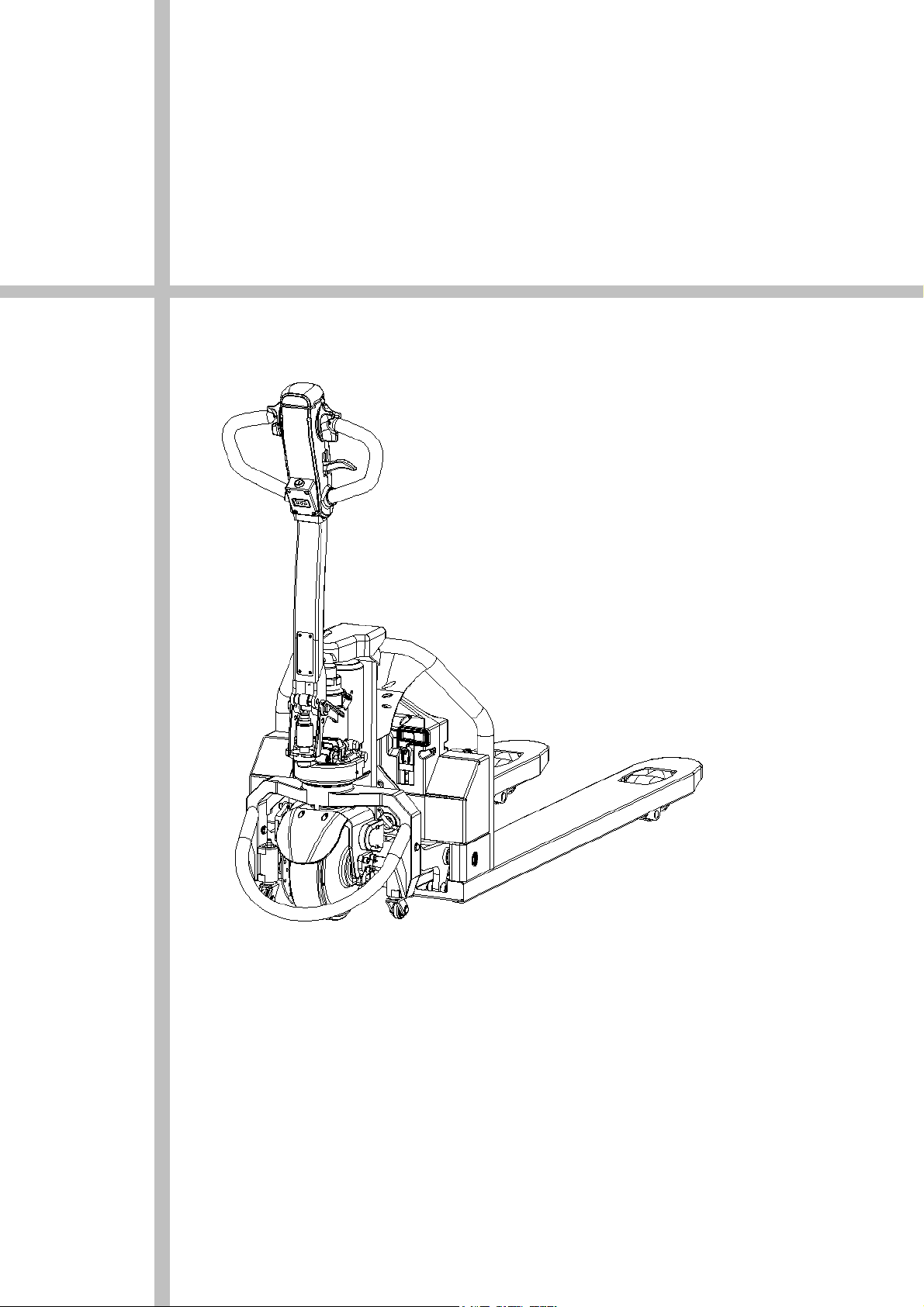

When handling goods on a slope, the operator must be very careful in

operation. The operator should operator in the upper part of the slope as

shown in the figure above.