1.9. Additional safety labels.

Keep all children, bystanders and helpers 15

meters from the machine.

Warning against flying objects wear helmet,

goggles and ear protection.

Warning: Danger from hot components,

especially exhaust - Keep clear of combustible

materials.

1.10. Additional safety instructions.

1.10.1. This machine may only be used for

trimming grass. NEVER use for other purposes,

as this may result in serious injury! Safety

instructions must be observed. DO NOT

EXPOSE YOURSELF OR OTHERS TO THE RISKS.

Follow these general instructions -

ALWAYS wear safety goggles for eye

protection.

Long hair must be tied back.

DO NOT wear loose clothing or jewelry that

could get caught in moving parts of the

machine. Safe, strong, non-slip safety shoes

should be worn.

It is recommended that the legs and feet

are fully protected, to protect themselves

during the operation against flying objects.

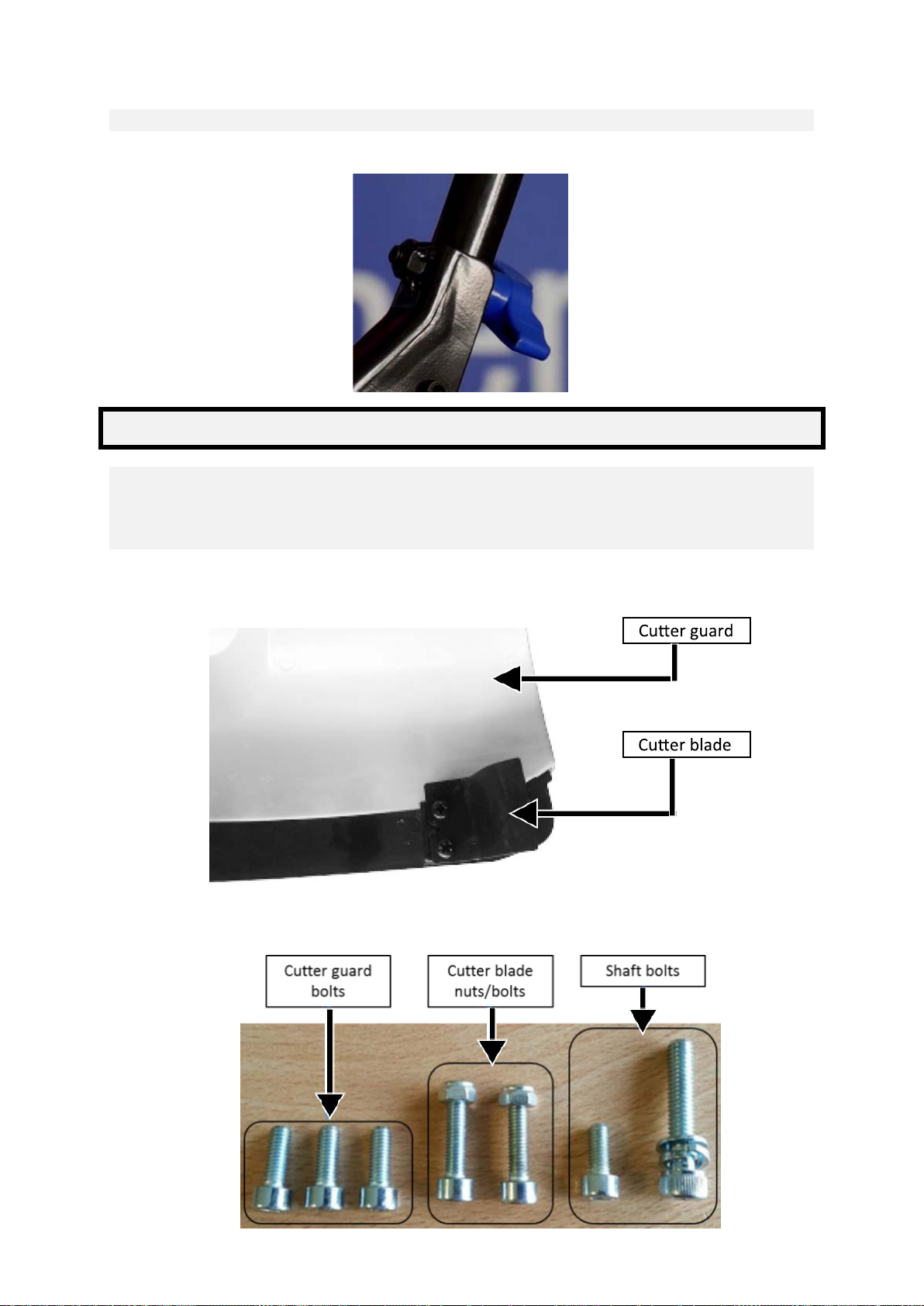

1.10.2. Check the entire machine for

loose/missing parts (nuts, bolts, screws, etc.).

Tighten/ replace before using the machine. DO

NOT use accessories with this machine other

than those recommended/supplied by the

manufacturer. Otherwise serious injuries to

the user or bystanders as well as damage to

the machine will result.

NEVER use the machine

with a saw blade attachment it is STRICTLY

FORBIDDEN.

Keep the handles free of oil and fuel.

ALWAYS use the correct interface handles

and shoulder strap.

DO NOT smoke when mixing fuel or when

filling the tank.

DO NOT mix fuel in an enclosed area or

near open fires.

Make sure there is sufficient ventilation.

Mix and store the fuel mixture in a

correctly marked container, which is

allowed by local regulations.

1.10.3. During and after use the engine and

exhaust will be very HOT you must keep all

your all parts of your body and clothing

including all combustible materials clear of the

engine and exhaust.

1.10.4. DO NOT use the machine during or

after rain, snow or sleet. The floor will become

slippery. DO NOT use the machine on a slope

or uneven ground or if there is the chance of

slipping or losing the stability.

1.10.5. If you trip or fall whilst machine is in

use you MUST immediately release the

throttle, and turn off the ignition switch.

1.10.6. If you hit any obstacles you must stop

the machine and remove the HT lead so that

you can inspect the machine. IF the machine is

damaged in any way you MUST get it repaired

before restarting work.

1.10.7. DO NOT use a damaged machine or a

machine with a blunt, cracked or damaged

cutter blade or trimmer head.

1.10.8. If any trimmed materials get tangled in

the nylon cord or cutting blade you MUST stop

the machine and remove the HT lead. Onley

then can you clear any blockages.

1.10.9. DO NOT wear rings and jewelry or

loose, dangling clothing that could get caught

in the machine. DO NOT wear footwear with

unprotected toes and DO NOT work barefoot

or without leg protection. In certain situations,

you have to wear head protection.

1.10.11.DO not use the brush cutter for

trimming trees.