Use the P-272 SIM Ignition module conversion kit to

replace a Fenwal ignition module for any boiler using a

touchscreen controller or a 5-button controller with

software version 3.11.4.

Note

the Fenwal module is not necessarily defective

when the boiler reports an Ignition Module error.

A mechanical error such as Low Water Cut-Off

may also cause Ignition Module alarms.

The earlier VFCs models were fixed-fire boilers that used

a controller with an integrated ignition module. Contact

the factory for fixed-fire VFC boiler replacement parts.

Pre-installation guidelines

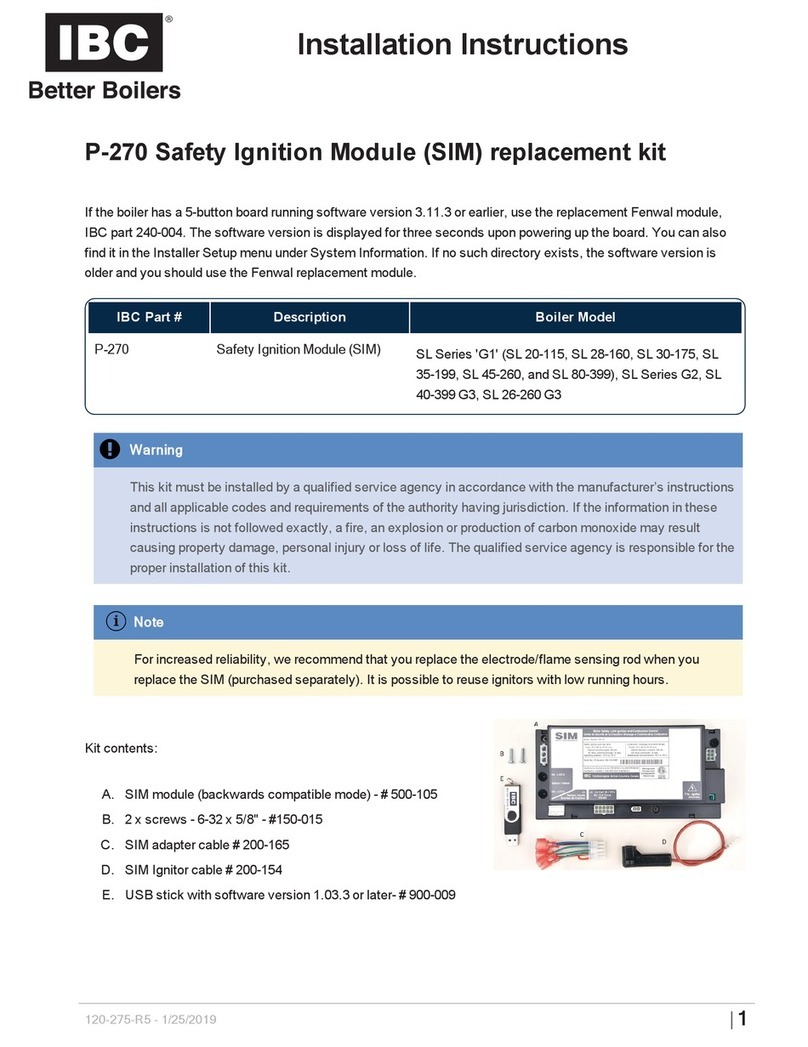

For increased reliability, we recommend that you replace

the electrode/flame sensing rod when you replace the

SIM (purchased separately). It is possible to reuse

ignitors with low running hours.

Installing a P-272 Ignition

module kit

Figure 1 Wiring connections to the SIM module

1. Remove any call for heat, and power off the boiler.

2. Remove the front door panel from the cabinet, and

allow the boiler to cool.

3. Only drain the boiler should the boiler’s water

be susceptible to freezing while the boiler is off.

4. Turn off the gas supply.

5. To remove the puck-shaped air pressure

sensor from its metal mounting bracket, lift it

straight upwards.

Figure 2 Lifting off the air pressure sensor

6. Unscrew the air pressure sensor mounting

bracket from the controller cabinet.

The Fenwal ignition module is mounted on the

back wall of the VFC, partly hidden by the

black intake air piping. You do not need to take

apart this piping nor remove the Fenwal.

7. Unplug the orange, blue, brown, and green

wires from the module. You can leave the

Fenwal module in place.

8. On top of the heat exchanger:

a. Unplug the ignitor cable boot from the

ignitor.

b. Connect the new 200-166 ignitor cable

firmly to the ignitor, then feed the cable

through the back of the heat exchanger,

passing over the top of the heat

exchanger mounting bracket (see Figure 3

). Remove the old ignition cable if