Page 4 of 18 Copyright © AVK Holding A/S, original version, rev. 1, 21-Jan-2023

3. Table of contents

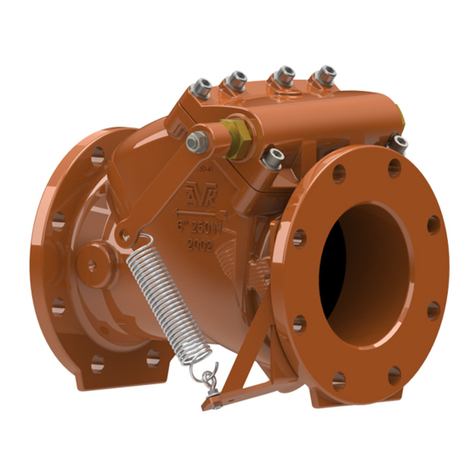

1. AVK series 41, swing check valves, exploded view...........................................................2

2. AVK series 41, parts list ....................................................................................................3

3. Table of contents...............................................................................................................4

4. Principle of operation.........................................................................................................5

5. Health and safety at work..................................................................................................6

6. Receiving and storage.......................................................................................................7

7. Installation and commissioning..........................................................................................8

7.1 Flow direction.............................................................................................................9

7.2 Lever and weight / spring (optional)............................................................................9

7.3 Adjusting lever and weight........................................................................................10

7.4 Installation of lever and weight .................................................................................12

7.5 Lever and spring, DN200 and below (optional).........................................................13

7.6 Lever and spring, DN250-300 (optional)...................................................................14

8. Application hazards.........................................................................................................15

9. Operation and maintenance............................................................................................15

9.1 Operation .................................................................................................................15

9.2 Maintenance.............................................................................................................15

9.3 Disassembly for inspection and cleaning..................................................................16

9.4 Renewal of shaft and bushings.................................................................................16

10. Decommissioning............................................................................................................17

11. Trouble shooting .............................................................................................................17

12. Recommended spare parts.............................................................................................18

13. Head Loss.......................................................................................................................18