Contents

Safety and environmental notices ........................v

About this publication .............................ix

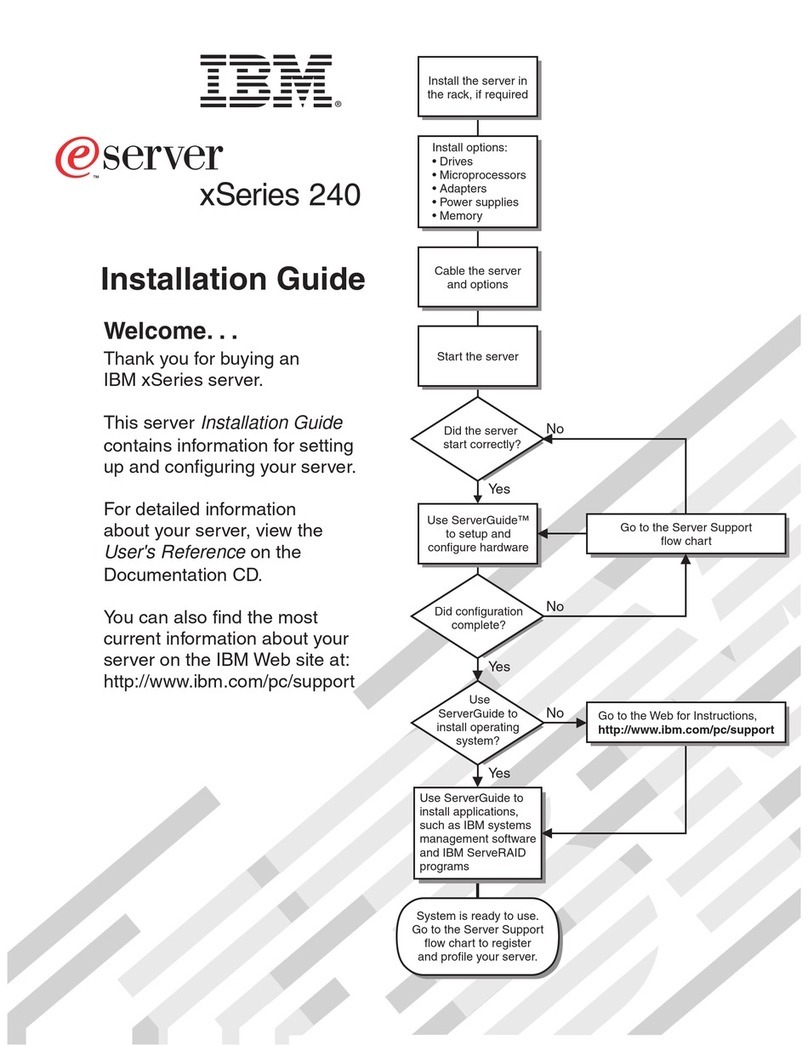

Cabling your server...............................1

Cabling your model 9405-520 with a console.........................2

Cabling a model 9405-520, 9406-520, 9406-525, or 9407-515 and a Thin Console ............2

Cabling a model 9405-520, 9406-520, 9406-525, or 9407-515 and a twinaxial console ...........9

Cabling your model 9406-520 with a console or interface ....................15

Cabling a model 9406-520, 9406-525, or 9407-515 to access the Advanced System Management Interface (ASMI) 15

Cabling a model 9406-520, 9406-525, or 9407-515 and the Hardware Management Console (HMC) .....20

Cabling the Operations Console attachment for model 9406-520, 9406-525, or 9407-515 .........26

Cabling a model 9405-520, 9406-520, 9406-525, or 9407-515 and a Thin Console ............32

Cabling a model 9405-520, 9406-520, 9406-525, or 9407-515 and a twinaxial console ..........39

Cabling your model 9406-525 with a console or interface ....................45

Cabling a model 9406-520, 9406-525, or 9407-515 to access the Advanced System Management Interface (ASMI) 45

Cabling a model 9406-520, 9406-525, or 9407-515 and the Hardware Management Console (HMC) .....50

Cabling the Operations Console attachment for model 9406-520, 9406-525, or 9407-515 .........56

Cabling a model 9405-520, 9406-520, 9406-525, or 9407-515 and a Thin Console ............62

Cabling a model 9405-520, 9406-520, 9406-525, or 9407-515 and a twinaxial console ..........69

Cabling your model 9407-515 with a console or interface ....................75

Cabling a model 9406-520, 9406-525, or 9407-515 to access the Advanced System Management Interface (ASMI) 75

Cabling a model 9406-520, 9406-525, or 9407-515 and the Hardware Management Console (HMC) .....80

Cabling the Operations Console attachment for model 9406-520, 9406-525, or 9407-515 .........86

Cabling a model 9405-520, 9406-520, 9406-525, or 9407-515 and a Thin Console ............92

Cabling a model 9405-520, 9406-520, 9406-525, or 9407-515 and a twinaxial console ..........99

Cabling your model 9110-510 with a console or interface ....................105

Cabling a model 9110-510 to access the Advanced System Management Interface (ASMI) ........105

Cabling a model 9110-510 and the Hardware Management Console (HMC).............110

Cabling a model 9110-510 to access the Integrated Virtualization Manager .............115

Cabling your model 9110-51A with a console or interface....................120

Cabling a model 9110-51A to access the Advanced System Management Interface (ASMI) ........120

Cabling a model 9110-51A and the Hardware Management Console (HMC) ............125

Cabling a model 9110-51A to access the Integrated Virtualization Manager .............130

Cabling your 9111-285 with a console or interface ......................135

Cabling a 9111-285 to access the Advanced System Management Interface (ASMI) ..........135

Cabling a 9111-285 and the Hardware Management Console (HMC) ...............137

Cabling your model 9111-520 with a console or interface ....................140

Cabling a model 9111-520 to access the Advanced System Management Interface (ASMI) ........141

Cabling a model 9111-520 and the Hardware Management Console (HMC).............146

Cabling a model 9111-520 to access the Integrated Virtualization Manager .............151

Cabling your model 9113-550 with a console or interface ....................156

Cabling a model 9113-550 to access the Advanced System Management Interface (ASMI) ........156

Cabling a model 9113-550 and the Hardware Management Console (HMC).............161

Cabling a model 9113-550 to access the Integrated Virtualization Manager .............166

Cabling your model 9115-505 with a console or interface ....................171

Cabling a 9115-505 to access the Advanced System Management Interface (ASMI) ..........171

Cabling a 9115-505 and the Hardware Management Console (HMC) ...............175

Cabling a model 9115-505 to access the Integrated Virtualization Manager .............180

Cabling your model 9131-52A with a console or interface....................185

Cabling a model 9131-52A to access the Advanced System Management Interface (ASMI) ........185

Cabling a model 9131-52A and the Hardware Management Console (HMC) ............190

Cabling a model 9131-52A to access the Integrated Virtualization Manager .............195

Cabling your model 9133-55A with a console or interface....................200

Cabling a model 9133-55A to access the Advanced System Management Interface (ASMI) ........200

© Copyright IBM Corp. 2004, 2007 iii