1. General .................................................................................................................................................... 1

1.1 Scope of manual ........................... ............................................................................................................. 1

1.2 Intended use .............................. ........................................... .................................................................... 1

1.3 General Safety Instructions ........................................... ............................................................................. 1

1.4 Standards and directives ....................... ......................... ......................... ................................................. 1

1.5 Symbols ............................................................ ..... .... ............................................................................... 1

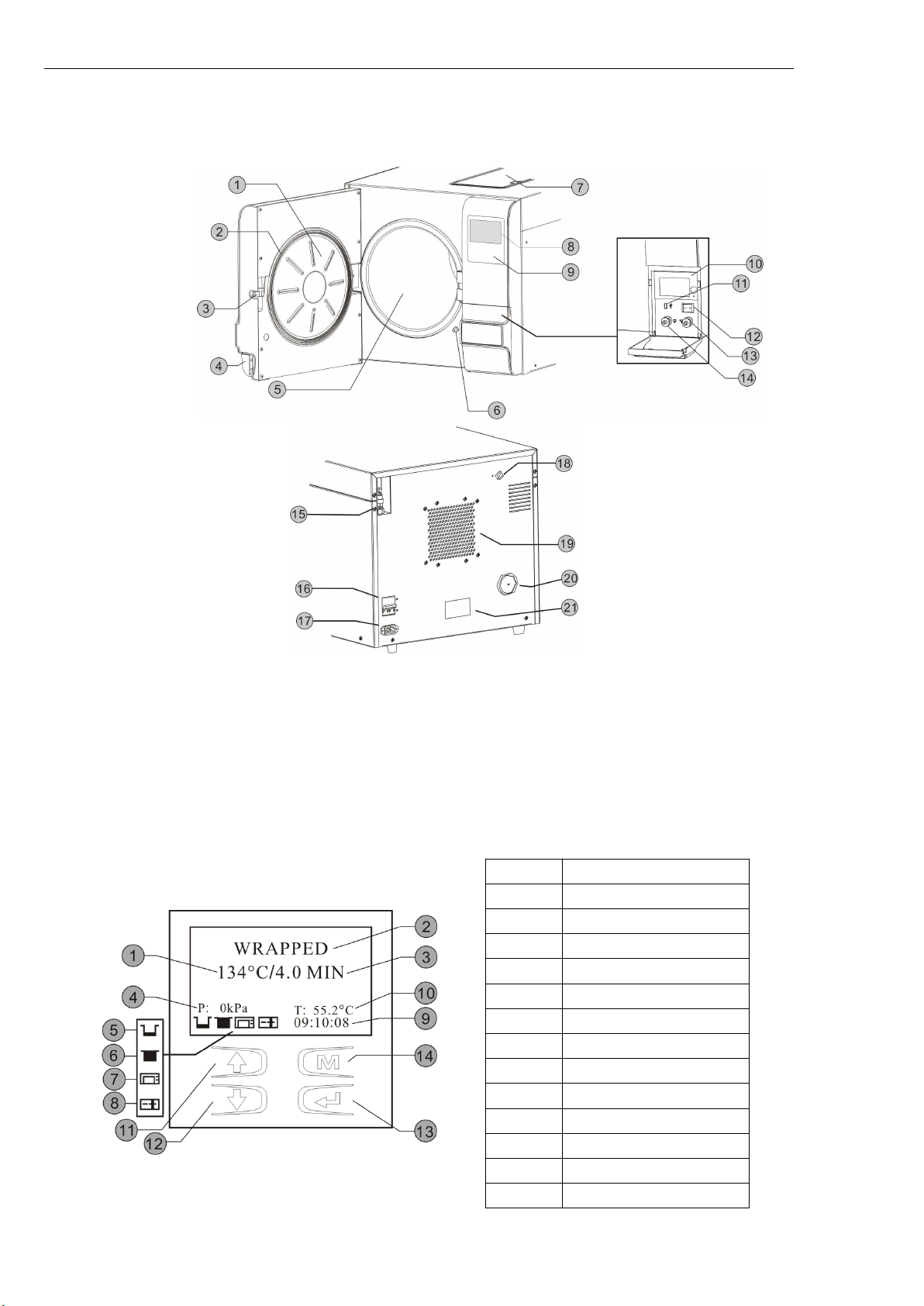

2. Description of the autoclave ........................................ ..... ......... ........................................................... 2

2.1 Autoclave views ........................................ ..... ......... ............................................................. .................. 2

2.2 Control panel ........................................ ..... ......... ................................................. .................................. 2

2.3 Technical Specifications ........................................ .......... ........................................................................... 3

2.4 Packing content ................................... ..... ......... ............................................... ........................................ 3

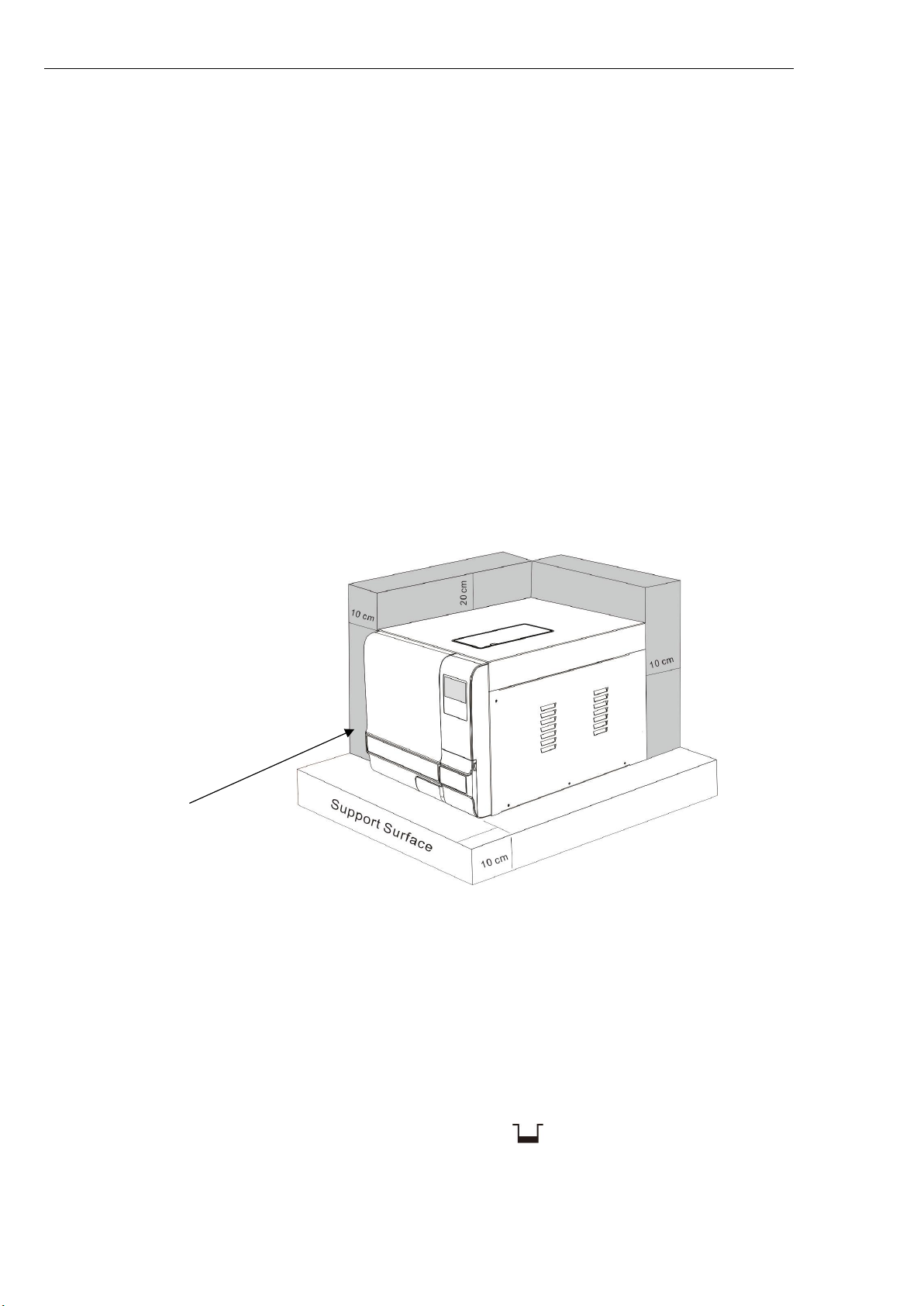

3. Installation ........................................ ..... ......... ......................................................... .......................... 4

3.1 General conditions ................................... ..... ......... .............................................................................. 4

3.2 Power supply connection .................................. ..... ......... ....................................................................... 4

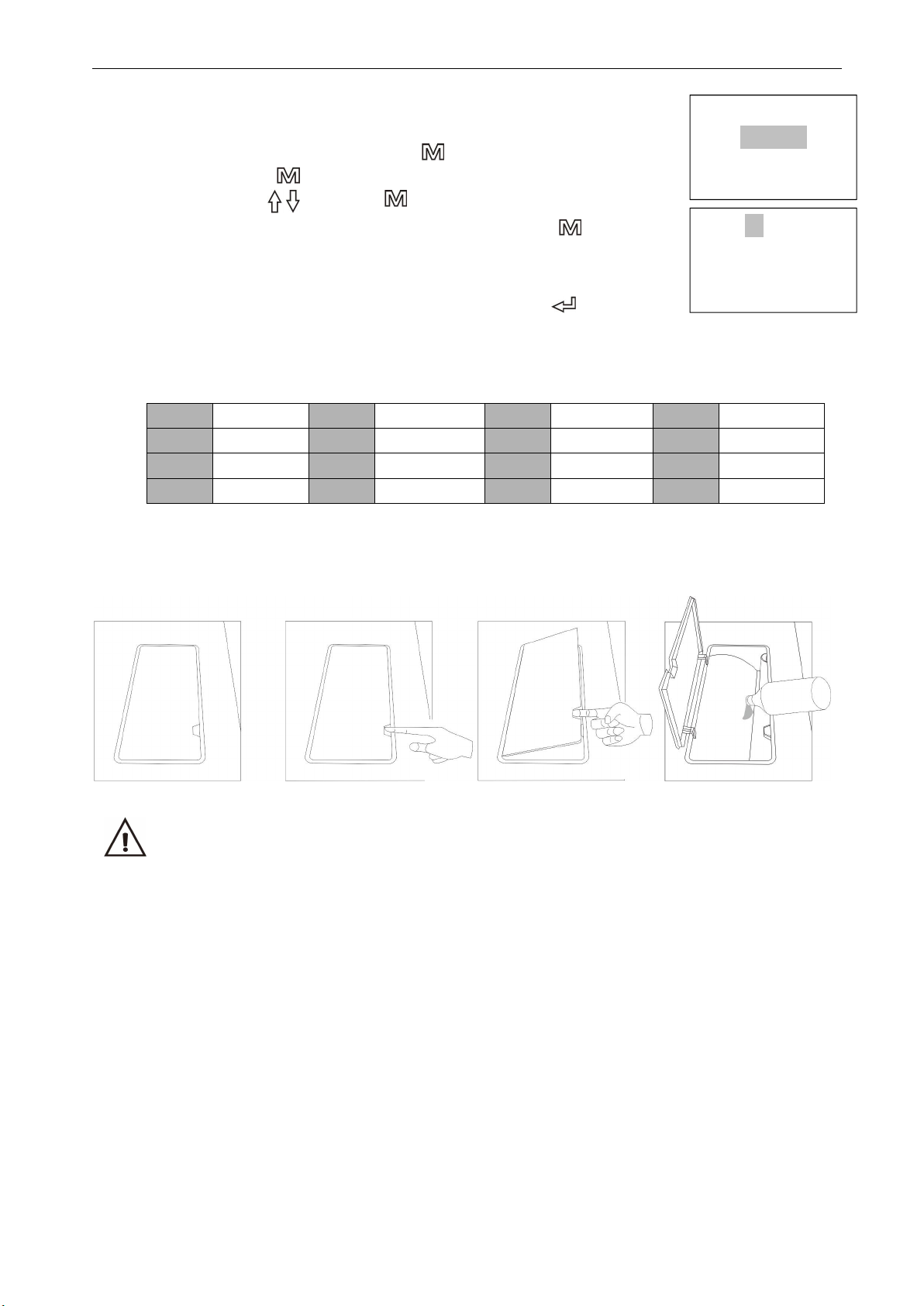

4. Setup ..................................... . ....................... ....................................................................................... 4

4.1 Basic set ..................... ....................... ................. ..................................................................................... 5

4.2 Fill the distilled Water Tank ....................... ....................... ....................... ................................................ 5

4.3 Preparation of the sterilization materials ................. ....................... ........................................................ 5

5. Operation ....................................... ...................... ...................... .......................................................... 6

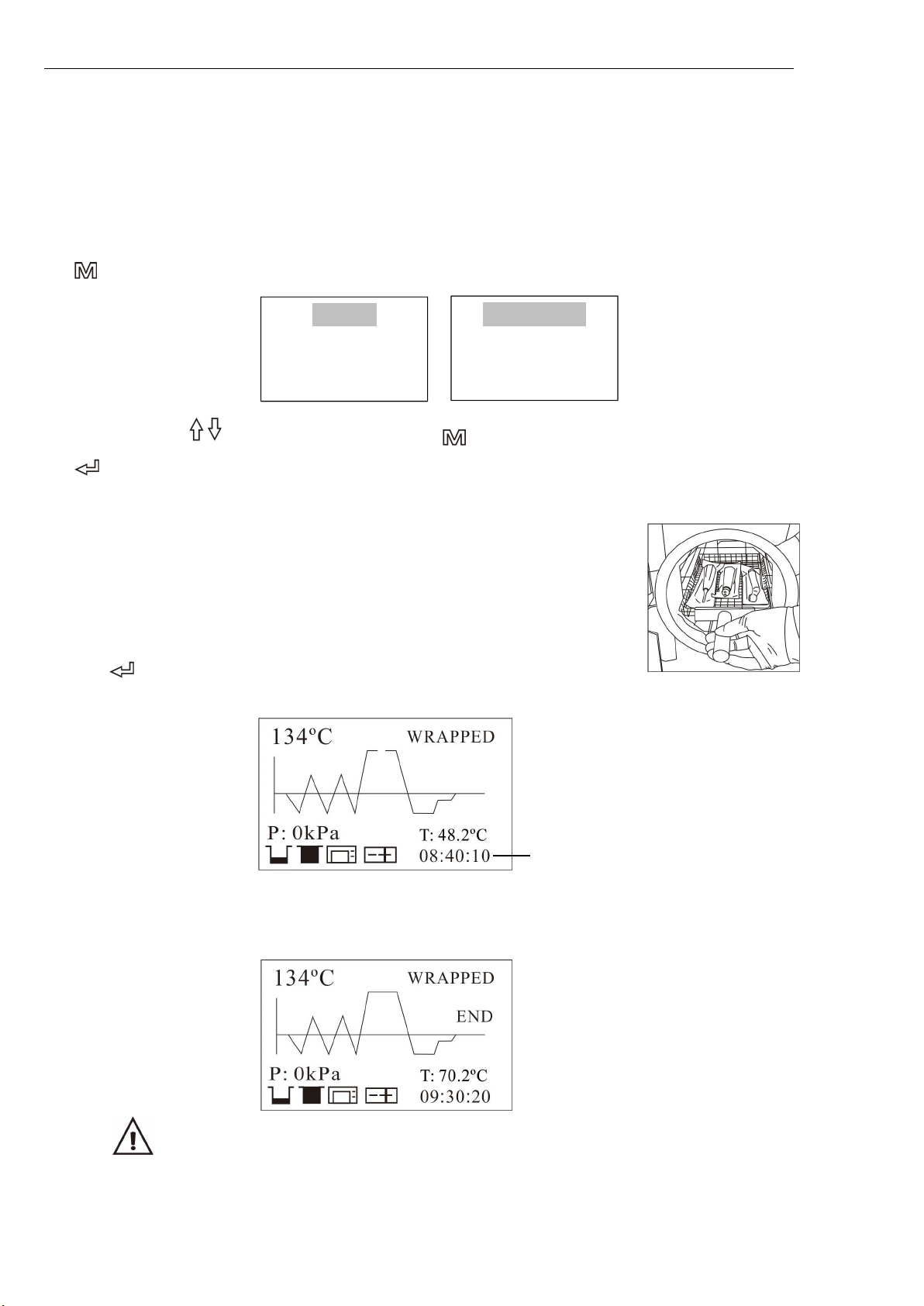

5.1 Select the program ....................... ...................... ...................... ............................................................... 6

5.2 Running the sterilization program ......................... ...................... ................. ........................................... 6

5.3 Start the sterilization program ............................ ...................... ............... ................................................ 6

5.4 End of cycle .......................................... ...................... ...................... ........................................................ 6

5.5 Manual abort the program .................. ...................... ................. ................................................................ 7

5.6 Test Programs ...................................... ...................... ...................... ......................................................... 7

5.7 Record of the cycle .................................................... ...................... ............. ............................................ 7

5.8 Printer ...................................... ...................... ...................... .................................................................... 8

5.9 Report ..................................... ...................... ...................... ..................................................................... 8

6. Advance settings ................................................................ .................. ..... ............................................. 10

6.1 Parameter ....................................... ...................... ...................... .............................................................. 10

6.2 Unit ........................................ ...................... ...................... ...................................................................... 10

6.3 Preheat .................................. ...................... ...................... ....................................................................... 10

7. Maintenance ..................................................... ...................... ...................... ........................................ 11

7.1 Clean the distilled water tank ....................... ...................... ...................................................................... 11

7.2 Replacement of the bacteriological filter ......... ...................... ...................... ............................................ 11

7.3 Clean Chamber, door seal, trays and tray Rack ............... ............. ........ ...... ............................................. 11

7.4 Door adjustment ............................. ...................... ...................... ........................................................... 12

7.5 Replacement of the door seal .............. ...................... ...................... ........................................................ 12

7.6 The drain valve .............................. ...................... ...................... ............................................................... 12

8. Error codes ....... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...................................................................... 13

9. Transportation and storage .............. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ................................... 14

10. Safety devices .................. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ................................................. 14

Appendix 1 - Water properties / Characteristics ......... ... ... ... ... ... ... ... .. ... ... ... ...... ... ... ... ... .................. 15

Appendix 2 - Diagrams of the sterilization programs ....... .............. ... ... ... ... .................... .......................... 16

Appendix 3 - Wiring diagram ................................ .................... ........... ... ... .............................................. 18

Appendix 4 - Hydraulic diagram .................... .................... ............... ...... ................................................... 19