Page 8

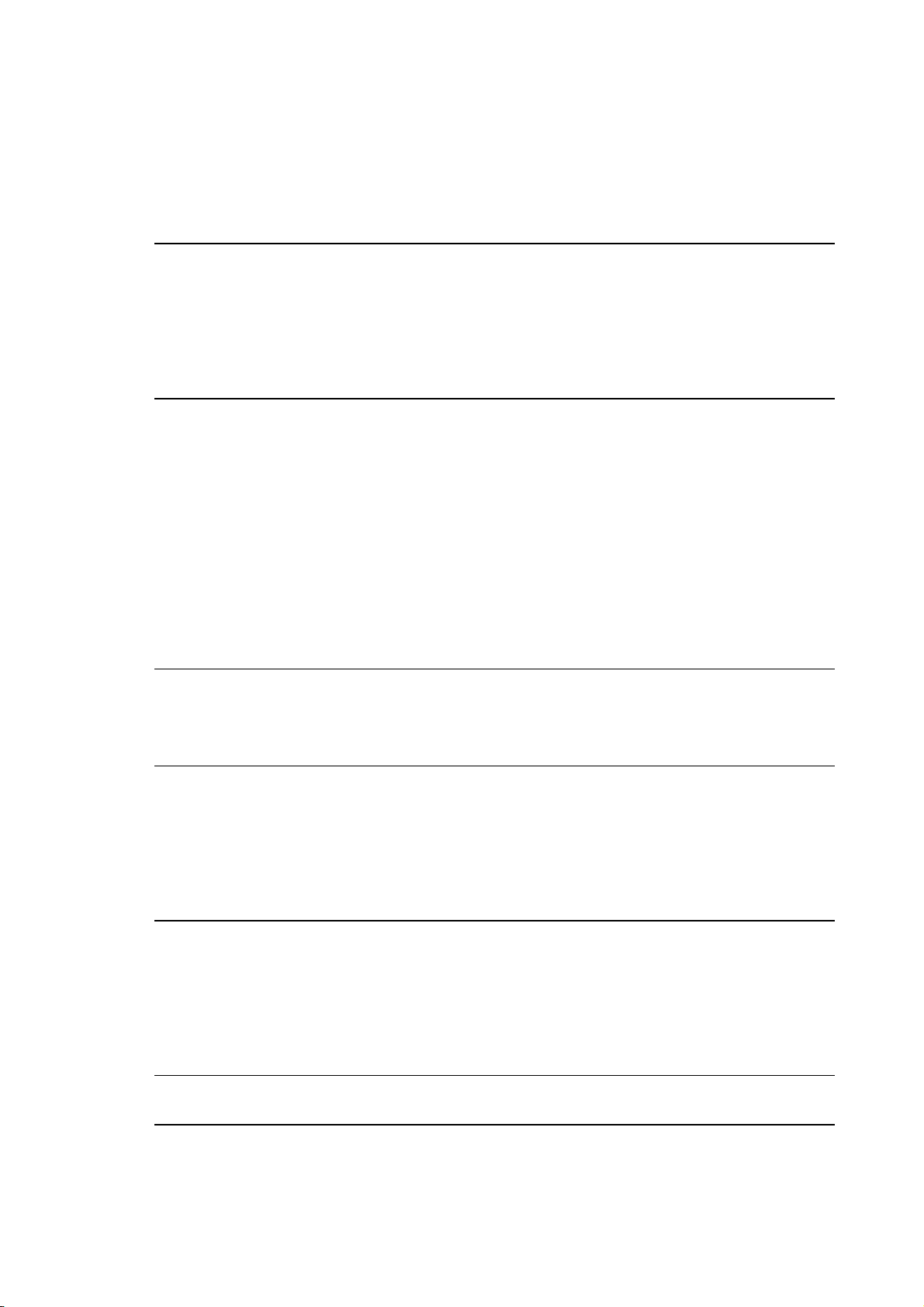

Our harness is supplied with the adjustment locked. To change the setting, you

must first remove the strap from the lock, then you can adjust the inclination of the

torso to make it more vertical by pulling the strap forward, or more reclined by

pulling the light grey strap in the opposite direction.

A sitting position ensures a low inertia and thus prevents twisting. The

horizontal position reduces aerodynamic drag and allows best glide in

accelerated flight.

Adjusting the tilt of the seat board

This adjustment varies the angle

between the legs and the back

(seating depth), distributing the load

between the seat and the back,

thereby providing the pilot with

greater comfort. If you want to

change the adjustment, you must

first loosen the strap. The more the seat board is tilted backwards, the easier it is

to "slip in" into the harness after takeoff.

Adjustment of shoulder straps

Shoulder-strap adjustment enables the harness to be adjusted to the pilot’s height.

The adjustment buckle is situated low down, near the rear edge of the seat.

The shoulder-straps also support part of the torso weight to improve comfort. After

that you have determined the correct position for the seat and back, adjust the

shoulder straps so that they are in contact with your shoulders, neither too loose

nor too tight.

The adjustment of the shoulder straps is done while standing. They are dressed so

far that you can just stand upright.

The shoulder straps must be tightened in a relaxed position so that a light

pull is felt on the shoulders.

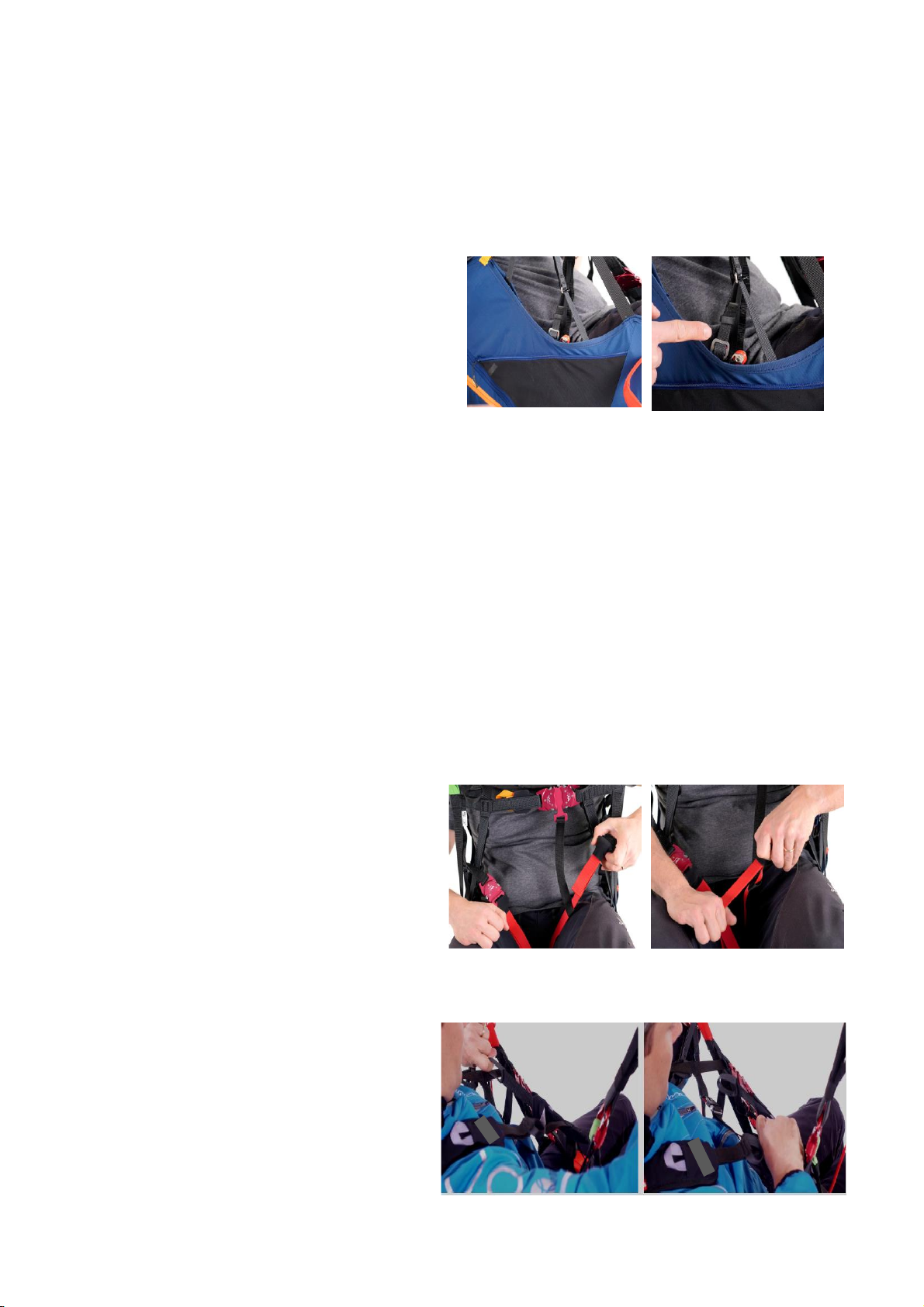

Adjustment of leg straps

Pull the leg straps tight before

starting, but make sure they do

not cut in or squeeze.

Due to a special design the leg

straps will not hinder your running

at the start. Because they are tied

tight, the front of the seat is lifted

and helps you getting into the

harness. By slipping back in the gear, the leg straps loosen a bit after start.

Adjustment of chest straps

The adjustment of the harness

chest strap controls the

distance between karabiners

and affects the handling and

stability of the glider.

The risk of twisting is also

strongly affected by the seating

position of pilot.