33

CONTENTS

ON CONSIGNMENT OF THE MACHINE .............................................................................................................................................5

INTRODUCTORY COMMENT ............................................................................................................................................................5

INTENDED USE................................................................................................................................................................................5

SERIAL NUMBER PLATE..................................................................................................................................................................5

TECHNICAL DESCRIPTION...............................................................................................................................................................6

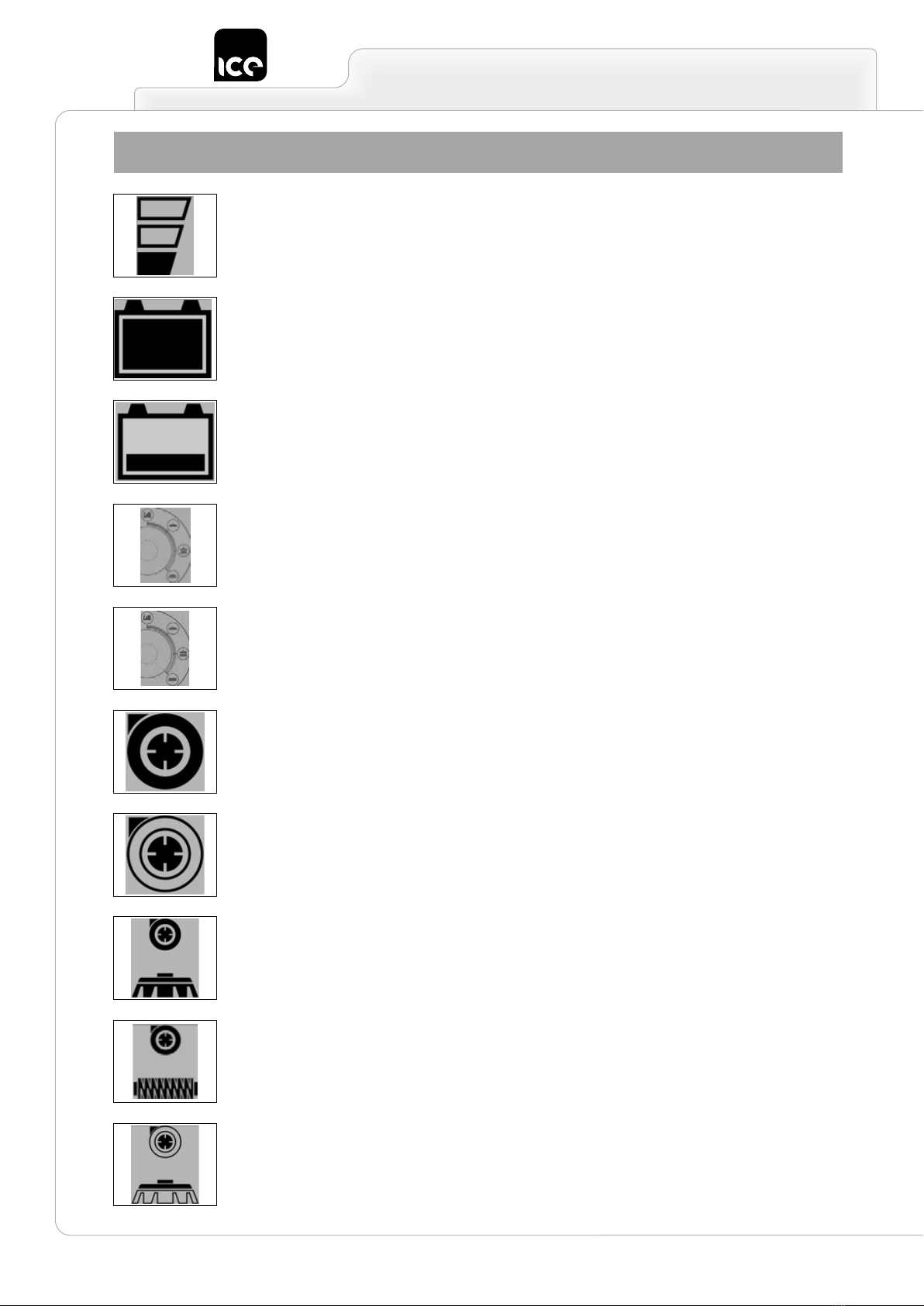

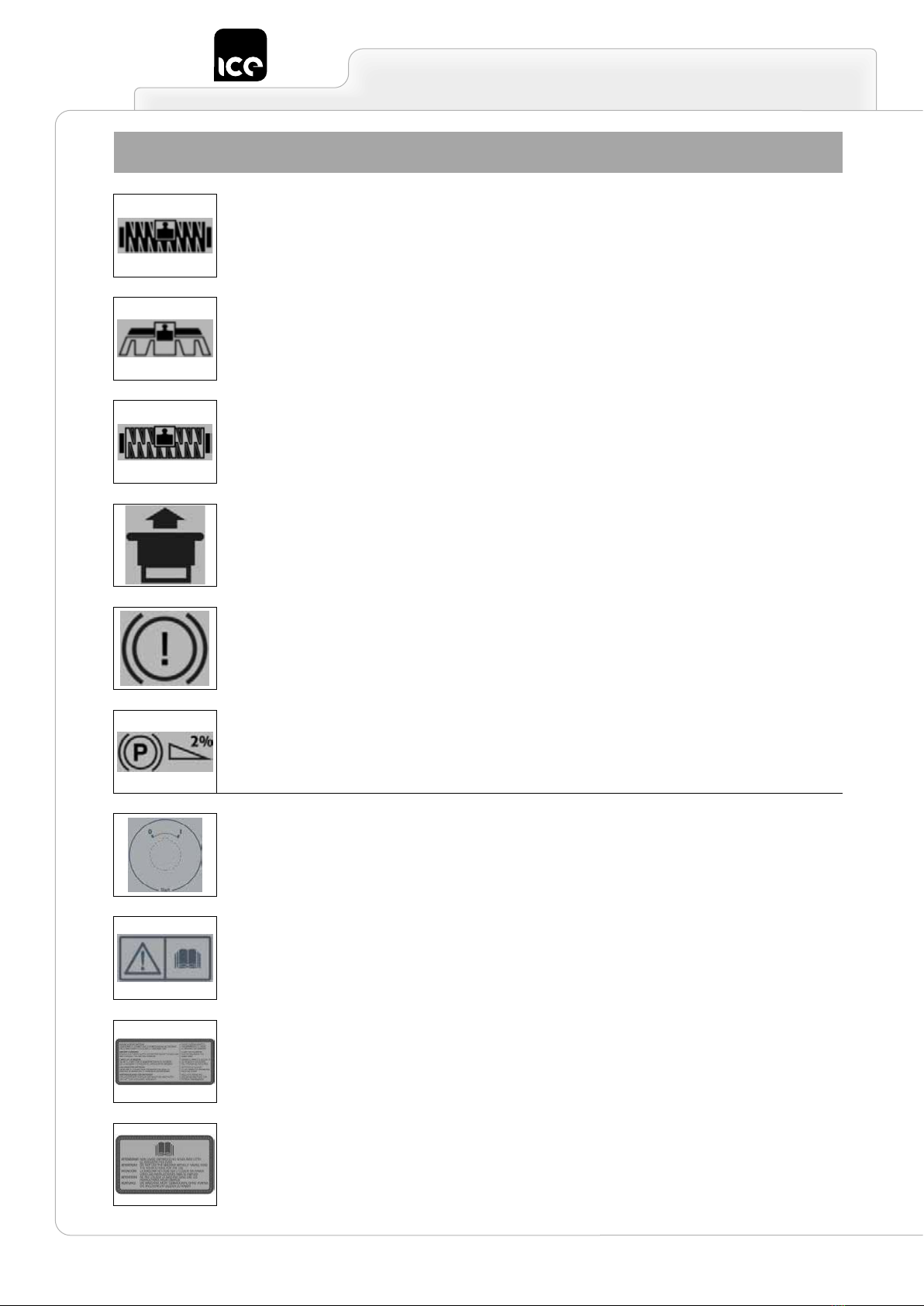

SYMBOLS USED ON THE MACHINE................................................................................................................................................. 7

GENERAL SAFETY REGULATIONS .................................................................................................................................................12

MACHINE PREPARATION...............................................................................................................................................................14

1.HANDLING THE PACKED MACHINE .........................................................................................................................14

2.HOW TO UNPACK THE MACHINE.............................................................................................................................14

3.HOW TO MOVE THE MACHINE ................................................................................................................................. 17

4.CONTROL PANEL COMPONENTS ............................................................................................................................ 17

5.STEERING COLUMN COMPONENTS .......................................................................................................................18

6.FOOTBOARD COMPONENTS.................................................................................................................................... 18

7.SIDE COMPONENTS OF THE MACHINE .................................................................................................................. 18

8.REAR COMPONENTS OF THE MACHINE.................................................................................................................19

9.SEAT SUPPORT COMPONENTS............................................................................................................................... 19

10.FRONT MACHINE COMPONENTS ............................................................................................................................ 20

11.MACHINE SAFETY .....................................................................................................................................................20

12.TYPE OF BATTERY .................................................................................................................................................... 21

13.BATTERY HOPPER MAINTENANCE AND DISPOSAL..............................................................................................21

14.FITTING THE BATTERIES INTO THE MACHINE.......................................................................................................21

15.CONNECTING THE BATTERIES AND BATTERY CONNECTOR..............................................................................22

16.CONNECTING THE BATTERY CHARGER ................................................................................................................22

17.HOUR COUNTER........................................................................................................................................................24

18.BATTERY CHARGE LEVEL INDICATOR ................................................................................................................... 24

19.WORKING FORWARD SPEED...................................................................................................................................24

20.FILLING THE SOLUTION TANK WITH WATER .........................................................................................................24

21.DETERGENT SOLUTION ...........................................................................................................................................26

22.ASSEMBLING THE SQUEEGEE ................................................................................................................................26

23.ASSEMBLING THE DISK BRUSHES (only for R-SCRUB 90D versions)....................................................................27

24.SERVICE BRAKE ........................................................................................................................................................27

25.FRONT HEADLIGHTS.................................................................................................................................................28

26.BLINKING LIGHT (OPTIONAL) ...................................................................................................................................28

27.SEAT ADJUSTMENT .................................................................................................................................................28

PREPARING TO WORK...................................................................................................................................................................29

1.PREPARING TO WORK..............................................................................................................................................29

2.WATER SYSTEM ENGAGEMENT..............................................................................................................................30

WORK............................................................................................................................................................................................31

1.STARTING WORK....................................................................................................................................................... 31

2.EMERGENCY BUTTON ..............................................................................................................................................34

3.SERVICE BRAKE ALARM ENGAGED........................................................................................................................34

4.ELECTRIC BRAKE FAULT ALARM ............................................................................................................................34

5.DETERGENT ADJUSTMENT......................................................................................................................................35

6.REGULATING THE FORWARD MOVEMENT WORK SPEED ...................................................................................36

7."ECO" DEVICE ............................................................................................................................................................36

8.BRUSH HEAD UNIT EXTRA PRESSURE ..................................................................................................................37

9.FRONT HEADLIGHTS.................................................................................................................................................38

10.BUZZER ......................................................................................................................................................................38

11.OVERFLOW DEVICE ..................................................................................................................................................38

AT THE END OF WORK ..................................................................................................................................................................39

DAILY MAINTENANCE ...................................................................................................................................................................41

1.EMPTYING THE RECOVERY TANK ..........................................................................................................................41

2.EMPTYING OF THE SOLUTION TANK ......................................................................................................................41

3.EMPTYING THE DEBRIS HOPPER (valid only for R-SCRUB 90C versions) .............................................................42

4.CLEANING THE SQUEEGEE BODY ..........................................................................................................................42

5.CLEANING THE DISK BRUSHES (valid only for R-SCRUB 90D versions) ................................................................43

6.CLEANING THE CYLINDRICAL BRUSHES (valid only for R-SCRUB 90C versions) ................................................. 44