9

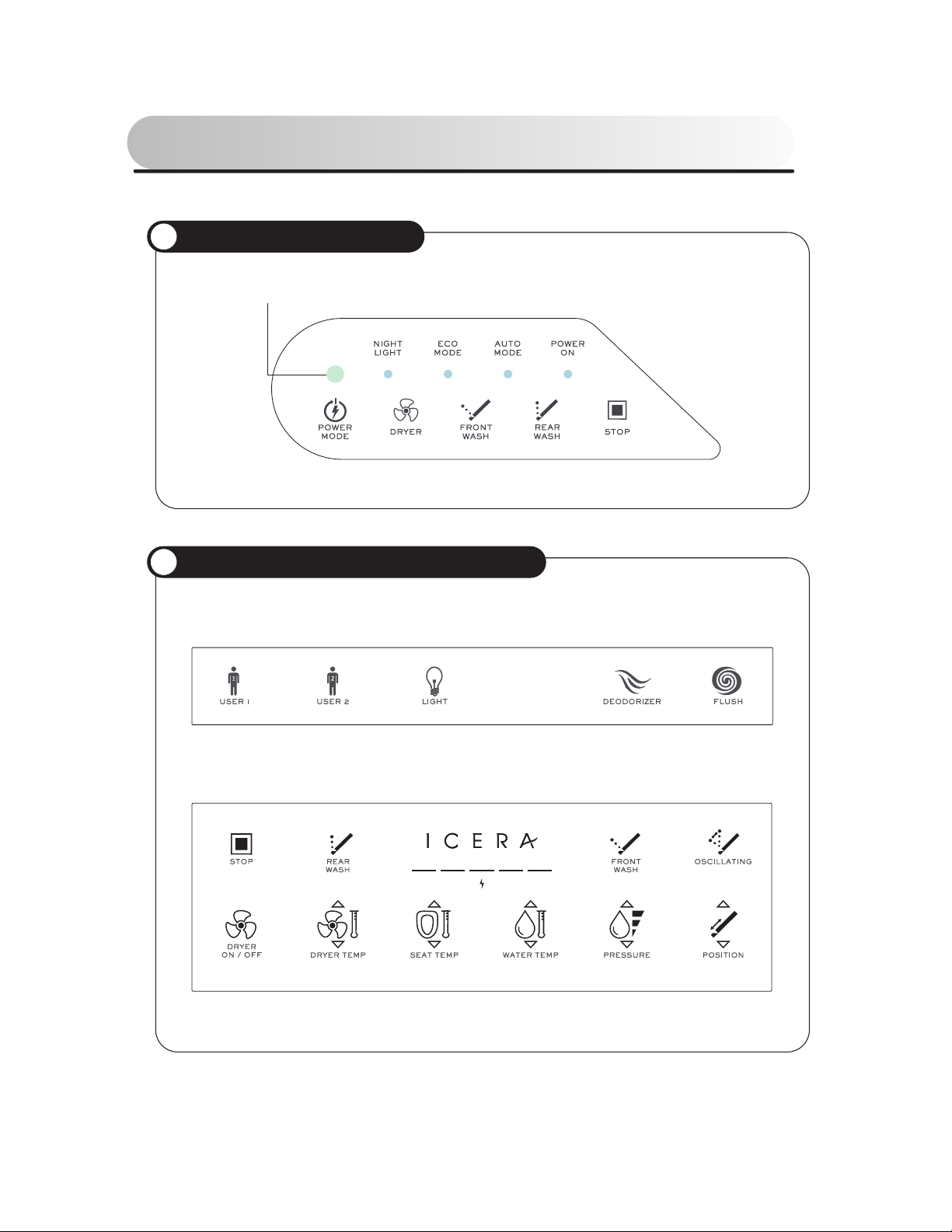

Funcons & Operaon

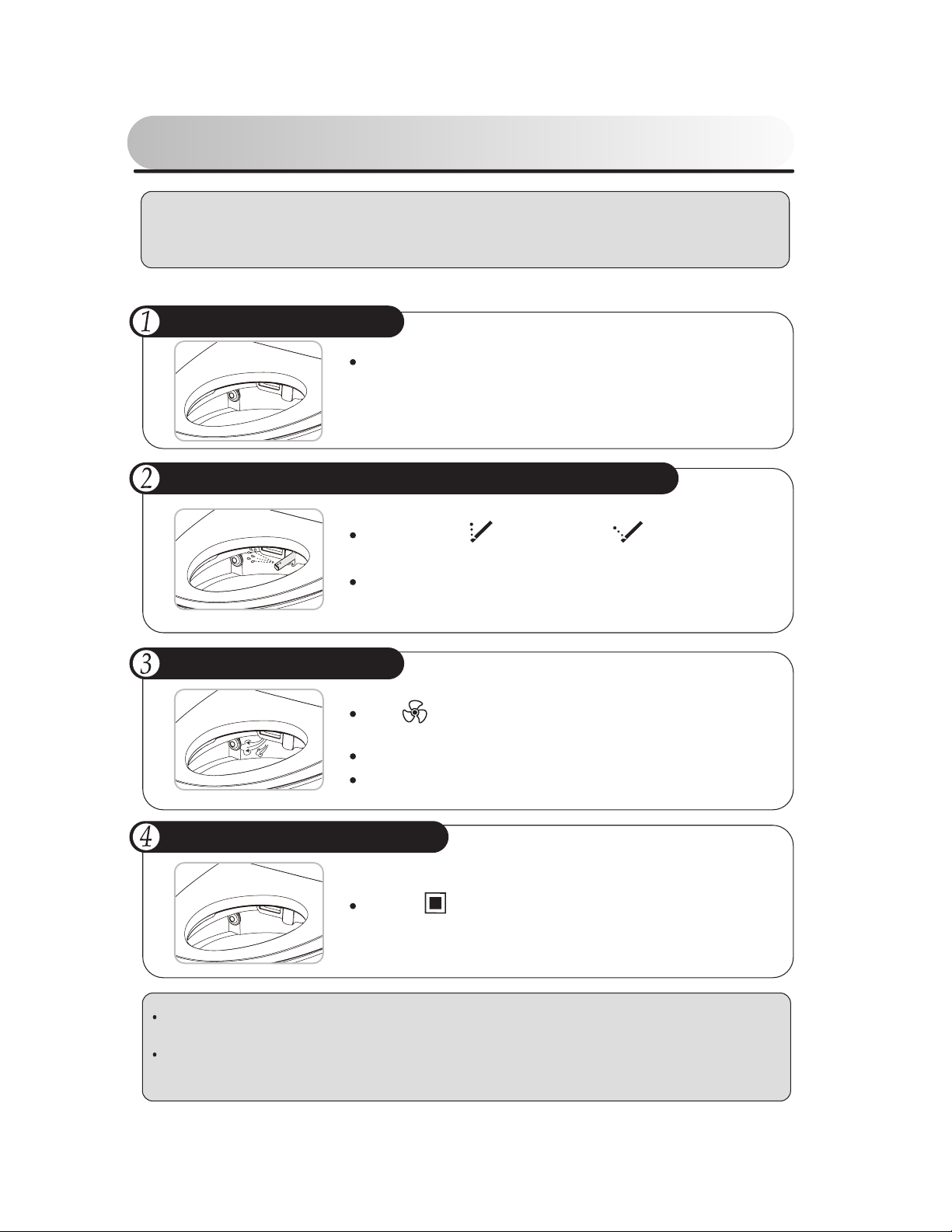

The nozzle system is both sanitary and effecve. The self-cleaning nozzle has separate secons for the front and rear

wash cycles. It is internally treated with an anbacterial nano-silver compound for added sterility. The nozzle is

automacally sanzed before and aer each use.

The nozzle should also be cleaned manually periodically. Using the control panel located on the seat, press the

REAR WASH and FRONT WASH buons at the same me. Clean the nozzle manually with a so brush.

Press the STOP buon on the control panel to return the nozzle to its resng posion. The self-cleaning funcon

will then operate.

The seat temperature will automacally lower when set to the highest seng if the seat is occupied for more than 30

minutes to protect the user against low-grade burns.

Burn Protecon

Nozzle Cleaning

09

User Presets

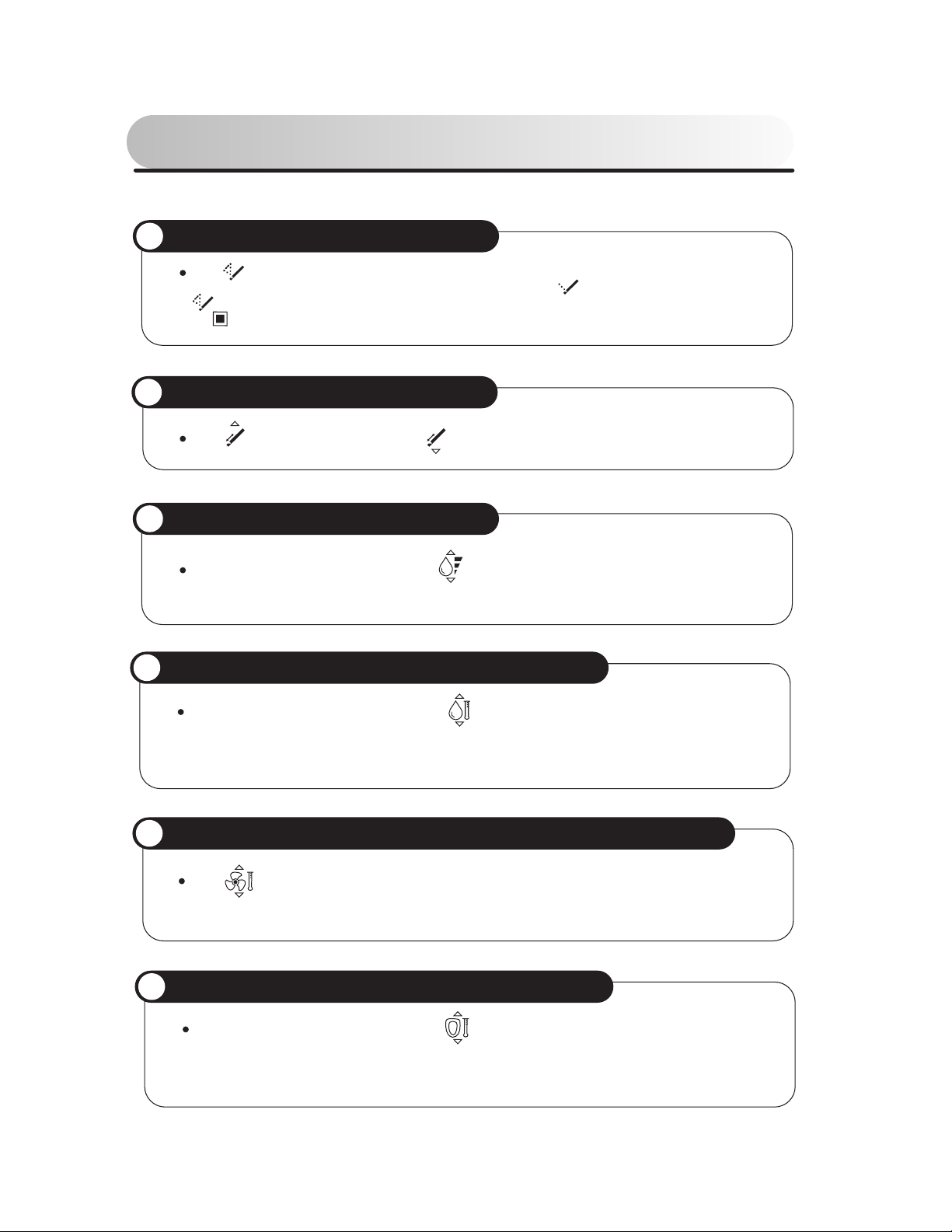

SAVING USER PRESETS: Set water pressure and temperature, nozzle posion, dryer temperature and seat temperature

to the desired sengs, then hold the buon for 4 seconds to save. A long beep will sound once the sengs are saved.

Repeat for .

ACTIVATING USER PRESETS: Quickly press and release the user preset desired to acvate. A short beep will sound

when the user preset is acvated.

STANDARD: In Standard mode, the seat temperature will be maintained at the seng last selected by the user.

AUTO: Press the POWER MODE buon on the seat control panel to acvate the AUTO power saving mode. In

AUTO power saving mode, the seat temperature will be maintained at 86° F (30° C). Once occupied, the seat

temperature is fully adjustable via the remote control.

ECO: For even greater energy-efficiency, press the POWER MODE buon on the seat control panel twice to

acvate the ECO power saving mode. In ECO power saving mode, the seat will be maintained at room temperature.

When a light is turned on in the bathroom, the seat will switch to AUTO power saving mode and revert back to ECO

power saving mode when the light is no longer detected.

Power Saving ModesPower Saving Modes

Power On/Off

To turn the unit off, hold the POWER MODE buon on the seat panel for 4 seconds (unl the LED lights shut off).

To turn the unit on, press any buon on the remote except the water, dryer and nozzle adjustment buons.

Power On/Off

In the event of a power outage or failure, the temp. and pressure sengs will default to the last used sengs when the

seat is powered on again.